Name: Rachel Rivera

Title: Acting Instrument Design Laboratory Team Lead

Formal Job Classification: Technical Manager

Organization: Code 550

What do you do and what is most interesting about your role here at Goddard? How do you help support Goddard’s mission?

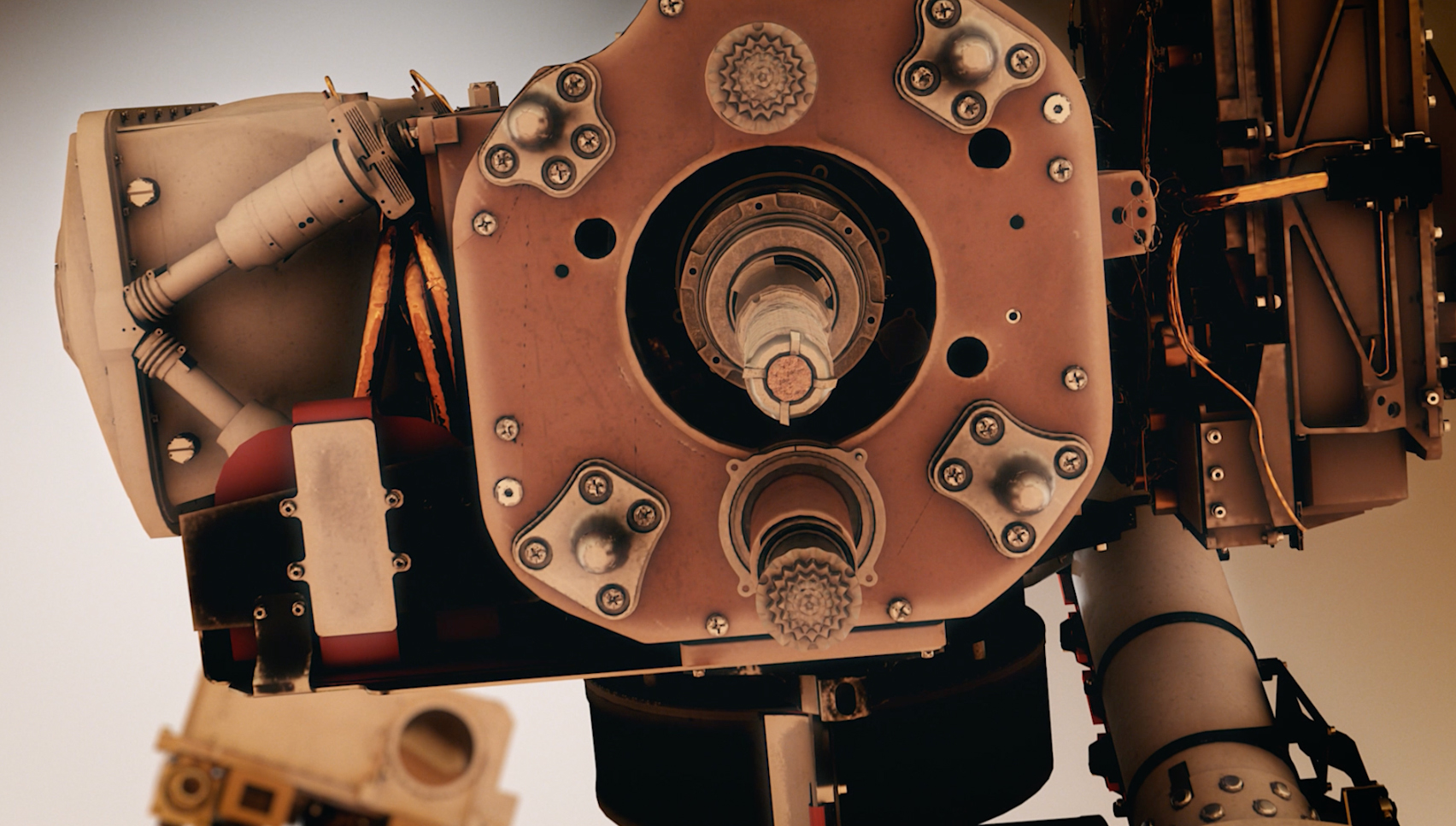

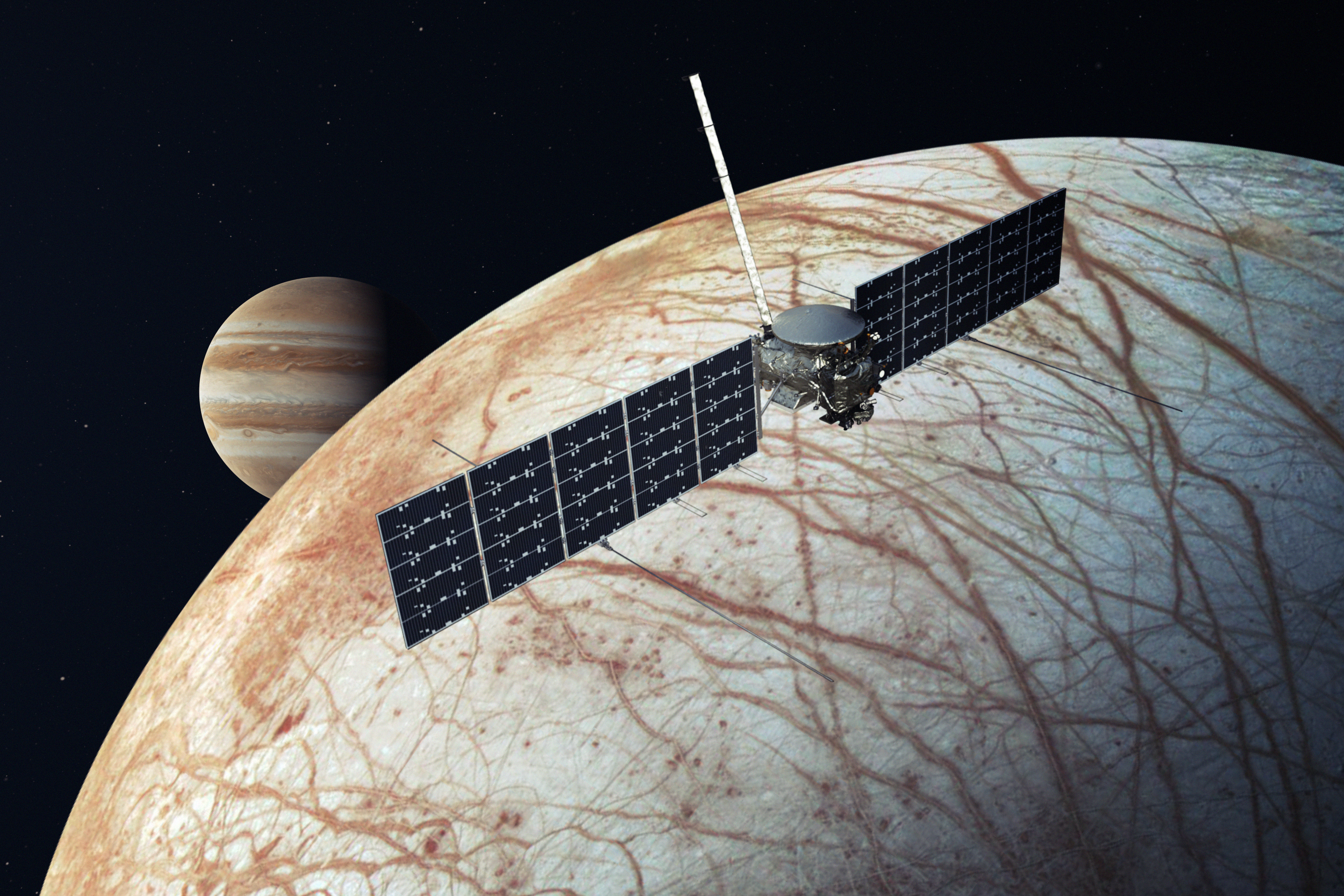

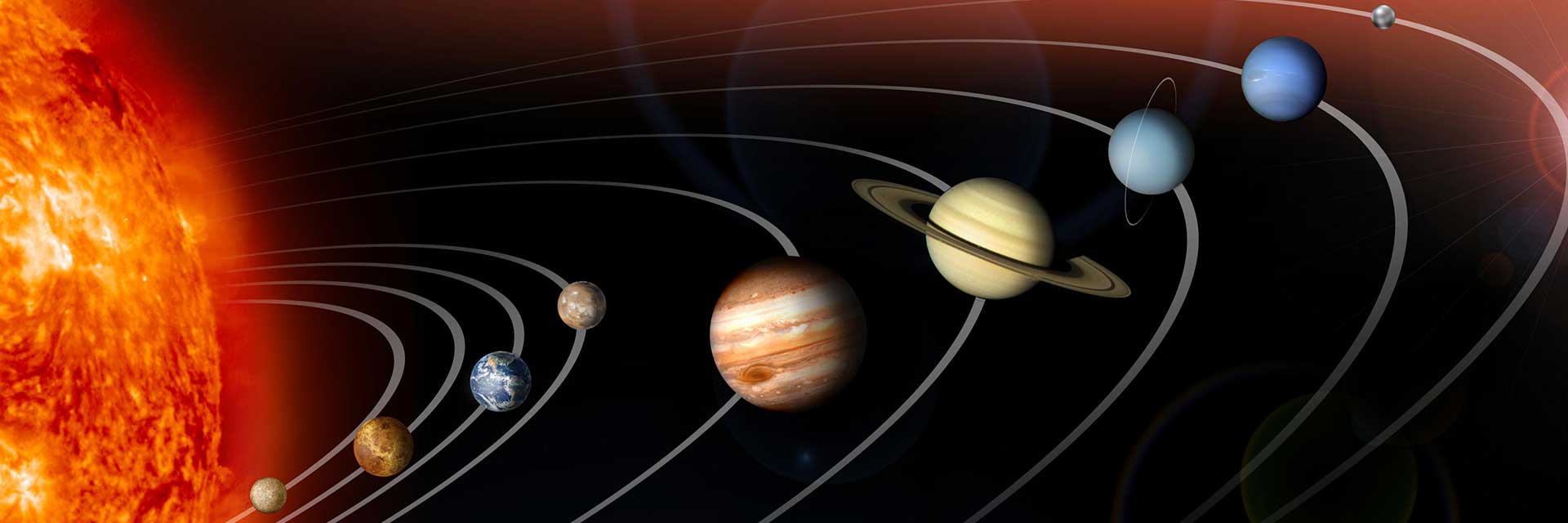

I am the acting team lead for the Instrument Design Laboratory (IDL) at Goddard’s Integrated Design Center (IDC). The IDL supports instrument concept studies in heliophysics, astrophysics, planetary and Earth sciences. Our lab creates the design concepts for instrument payloads that support the science on satellites.

Tell us about the Instrument Design Laboratory.

The magic in the IDL comes from our people, our processes and our tools. The tools facilitate our engineers’ expertise and our processes ensure that we produce a consistent, reliable product for our science customers.

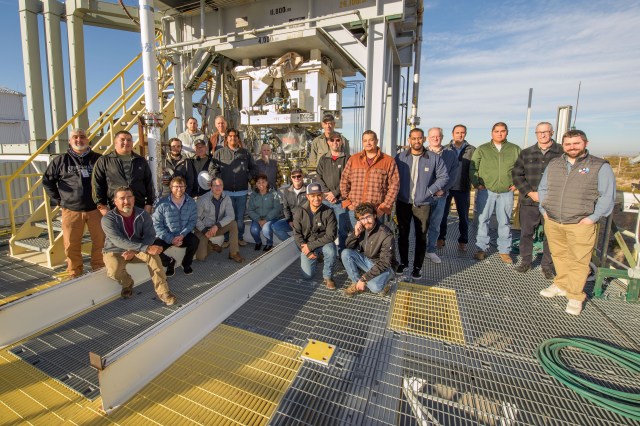

The IDL is full of computers manned by all types of engineers, each of whom has a different specialty, such as systems, thermal, mechanical, electrical, flight software, detectors, structural, optical and radiometrics. Each engineer comes to the lab with a particular expertise. We ensure that their computer is equipped with their particular software reflecting their expertise.

The engineering team conceptualizes, models and analyzes instruments that have not yet been built. We perform all the calculations and analyses to make sure that the instrument will meet the science needs.

What is the IDL’s final product?

Each design study is only one week. Our final product is a presentation from each engineering discipline including their calculations and analyses validating their portion of the design. For instance, the thermal engineer will support his or her concept that the overall instrument design will meet thermal operating requirements based on calculations using input from the other engineers, including those involved in producing heat and others involved in cooling the components.

How do you manage all the energy in the IDL?

There is no quiet time. We are a very dynamic environment where everything happens all at once. I coordinate everyone and keep us all marching to the same drumbeat so we can meet our single point design product in one week. There are many possible design outcomes, but we converge on a single design that meets the requested science requirements.

It takes a lot for me to get stressed. I am a middle child so I tend to go with the flow and try to make everyone happy. I’m also very adept with details and communicating and collaborating.

How do you facilitate communication within your engineering team?

The IDL is like a design war room. We all work in the same place for an entire week. Ours is a concentrated effort, with everyone all in the same room without other distractions, with everyone’s special tools and other’s expertise at their fingertips.

I produce the overall scope and list of design goals that need to be performed. Twice a day, at the beginning of the day and again after lunch, I lead a team tag-up to go over the daily status. We discuss what was completed and what needs to be completed to ensure that everyone is on the same page at the same time. After our tag up, people hold side bars for their various tasks. Everyone is in the same room at the same time holding different conversations, occasionally pulling others into their discussion.

What engineering collaboration inspires you?

A great, classic example of collaborative engineering comes from the Apollo 13 on-orbit incident involving the vital air filter. Engineers on the ground had to troubleshoot how to fit a square peg in a round hole. They were given the same pieces of hardware that were already aboard the Apollo 13 capsule, including duct tape and cardboard. The engineers all worked in the same room, collaboratively and without distraction, until they engineered a working solution. These ground engineers communicated their fix to the Apollo 13 astronauts and saved their lives.

Why did you become an engineer?

I always excelled in math. My fourth grade teacher would give me the math test but I would finish it so fast that I would end up helping her grade everyone else’s tests. I am fascinated with learning and love to read about science and the natural world. I love to find out how things work.

I received my bachelor’s degree in chemical engineering from The City College of New York. While at Goddard, I completed my master’s degree in engineering management from George Washington University in Washington, D.C.

How did you come to Goddard?

While I was an undergraduate, I was president of the American Institute of Chemical Engineers. In late 2003, we chartered a bus to a NASA recruitment event at Morgan State University. Goddard hired me on the spot to be a contamination control engineer. I worked for 11 years supporting multiple missions, such as the Solar Dynamics Observatory (SDO), the Lunar Reconnaissance Orbiter (LRO), the Landsat Data Continuity Mission (LDCM, later dubbed Landsat 8), the Deep Space Climate Observatory (DSCOVR) and the Laser Communication Relay Demonstration (LCRD).

How did you come to your current position as the Acting IDL Team Lead?

In 2015, I took a detail to become the deputy IDL team lead. I wanted to do something different. I always enjoy a challenge. Every study is different, so I am constantly learning which I find very rewarding. In 2018, I became the acting IDL team lead.

What is the one thing you would tell somebody just starting their career at Goddard?

I would tell them to do what they love to do because they will have to do it 8 hours a day, 5 days a week until they are 65 years old. Make the most out of life. I am fortunate that I look forward to going to work every day. Not everyone can say that.

Who is your science hero?

A big hero of mine is Mae Jemison, the first African-American woman in space. Mae was first a chemical engineer, then decided to become a medical doctor, and then she went on to be an astronaut, among other things. She is an inspiration that we can be anything we want to be!

My background is one of a successful immigrant story. My mom came to New York City as a child from the Dominican Republic and was granted political asylum. Our family had no money. My mother became a single parent with three children, working multiple jobs at a time to survive. Despite our hard upbringing, we overcame our circumstances to become successful individuals. My brother is a doctor. Like Mae Jemison, we believed that we could become anything we wanted to be — and we did!

What is the most important part of your life story that you want to pass on to your two young children?

I want to pass on a strong work ethic, a determination to be independent and to thrive. I also want them to learn to persevere through any tough times. And I want them to have passions and be kind, especially to those less fortunate. As a family, we volunteer often to give back to those in need.

Is there something surprising about your hobbies?

My father is a metallurgical engineer and my mother is a talented artist. She paints, she sings and she designs clothes. My work side comes from my father and my artistic side comes from my mother.

I enjoy scrapbooking with friends and even go to scrapbooking conferences. I also do crafts. I make little model cars and boats. I make all the family Halloween costumes. My daughter and I are constantly drawing together. There is always a fun craft project going on at home. My hot glue gun is always ON.