Students at the University of Idaho are advancing NASA technology that could improve wildfire spotting and farmland monitoring.

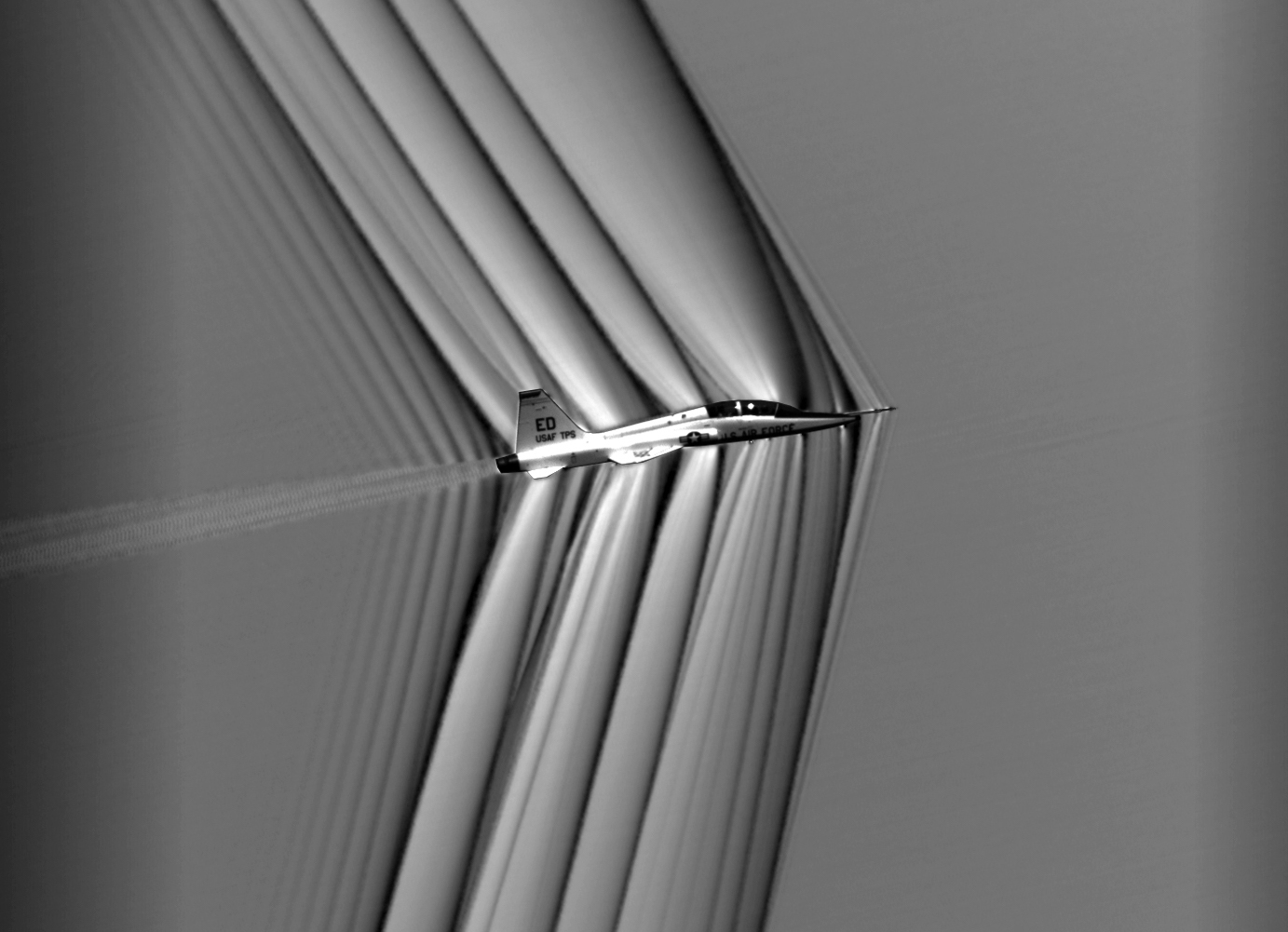

Through NASA’s Technology Transfer University, or T2U, students are looking at two NASA technologies for inspiration: Preliminary Research Aerodynamic Design to Lower Drag, or Prandtl-D, developed at Armstrong Flight Research Center in Edwards, California, and print-assisted photovoltaic assembly, or PAPA, developed at Marshall Space Flight Center in Huntsville, Alabama.

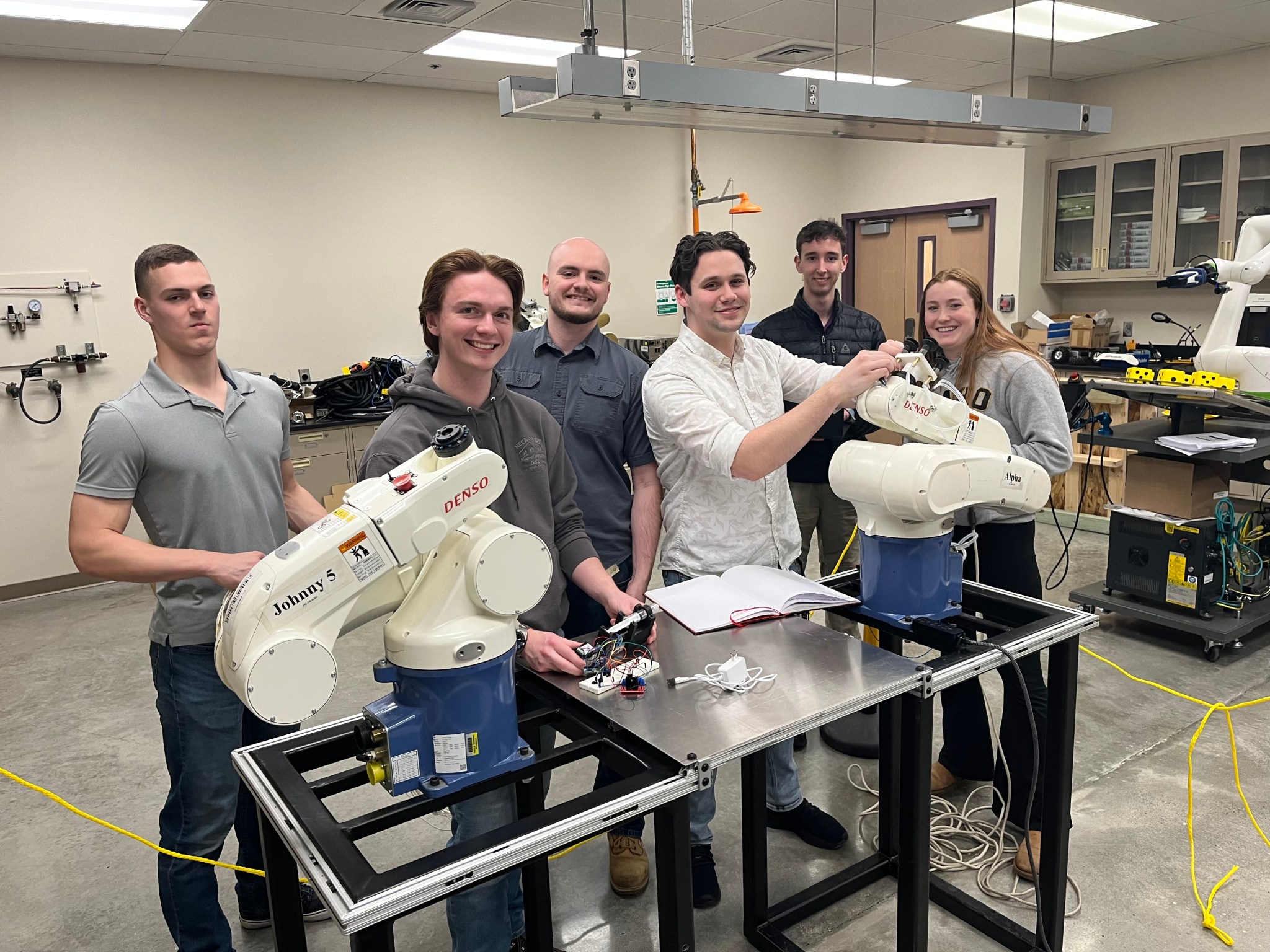

One group of university students is designing and building a remotely controlled aircraft based on Armstrong’s Prandtl-D tailless aircraft technology. The students’ work could lead to aircraft performing duties like farmland monitoring and wildfire spotting. Another student group is working with the Marshall technology, an automated assembly process for turning thin-film cells into larger photovoltaic arrays. The students are designing and will demonstrate a repeatable and automated assembly process for compiling thin-film cells into larger photovoltaic arrays using robotic armatures working in tandem. NASA is eyeing the use of such thin-film cells to power spacecraft and could even use the technology for creating solar arrays in space, enabling long-term spaceflight.

The university’s Interdisciplinary Capstone Design Program is using NASA technology to infuse real-world experiences into students’ engineering education. “I think it’s just a tremendous opportunity to engage so many students and faculty on working on really neat stuff that elevates NASA, elevates our university, and elevates our students,” said Matthew Swenson, Capstone’s director.

The partnership with University of Idaho is a good case study of T2U’s goal to link students with NASA research and technology to help create a new generation of engineers and entrepreneurs, said Brian Boogaard, NASA Armstrong’s T2U representative.

“The students are advancing the technology and helping to showcase additional commercial applications for each, all while developing engineering skills that will serve them throughout their careers,” Boogaard said.

With the Prandtl-D technology, the students are designing and building an electric-powered aircraft with an 11-foot wingspan. Looking like a boomerang, the Prandtl design mimics bird flight, using twists in its wingtips for maneuvering. NASA research indicates the design could provide an 12% reduction in fuel consumption. One group of students is focusing on manufacturing the aircraft, while another group is working on communication and controls.

Several challenges emerged upfront, including understanding the aerodynamics of the design, determining what payload-carrying capacity was desired, and how to power and control the vehicle.

“The whole thing is about student learning, designing and building something from scratch using engineering principles,” said Vibhav Durgesh, assistant professor of mechanical engineering. “Because there are no aerodynamics or aircraft design course here, they have to learn all of these things as they go along with this process.”

The students should begin flight tests this spring. The aircraft will launch with a bungee cord, fly for about an hour, and then land on its belly, with its commercially bought folding propellers collapsing back. If the aircraft proves reliable, Durgesh would like to borrow a sensor from another research group on campus so the students can compare their design’s performance against other air vehicles.

With the PAPA technology, students are working on the robotic equipment performing in tandem, alternating tasks as they build a solar array roughly two feet square. These small arrays could merge to form larger ones. The students tackle challenges, such as ensuring the adhesive is uniformly applied and developing panels that are not brittle, Swenson said.

“We won’t have anything that’s turnkey, that somebody could insert into their assembly line and start producing these things,” Swenson said. “But we like to think that we’re going to bring this up to a higher technical readiness level. It’s still going to require someone in industry who really wants to take this and run with it.”

Both projects are recruiting business students to develop business plans and marketing pitches. They will complete in regional pitch competitions and hopefully drum up interest from industry, Swenson said.

“We’re just grateful and honored that we got to work on both of these super special and advanced technologies and create these opportunities for our students,” Swenson said. “We want to have students who are really passionate and energetic about engaging in these projects so that they really take ownership and invest a lot of their own time and effort and make the best out of them.”

To learn more about NASA’s T2U program, visit https://technology.nasa.gov/t2u