Suppose an astronaut needed to make a repair to a piece of equipment on the International Space Station. Today, astronauts aboard the International Space Station depend on cargo resupply missions to ferry parts and tools from Earth, sometimes waiting weeks or months for critical maintenance supplies. As we venture farther into the solar system, these cargo resupply missions will become more costly and complex, compelling NASA to consider alternate options for spacecraft supplies. Rather than stock a “spare parts” drawer, what if tools and equipment could be made right there in space?

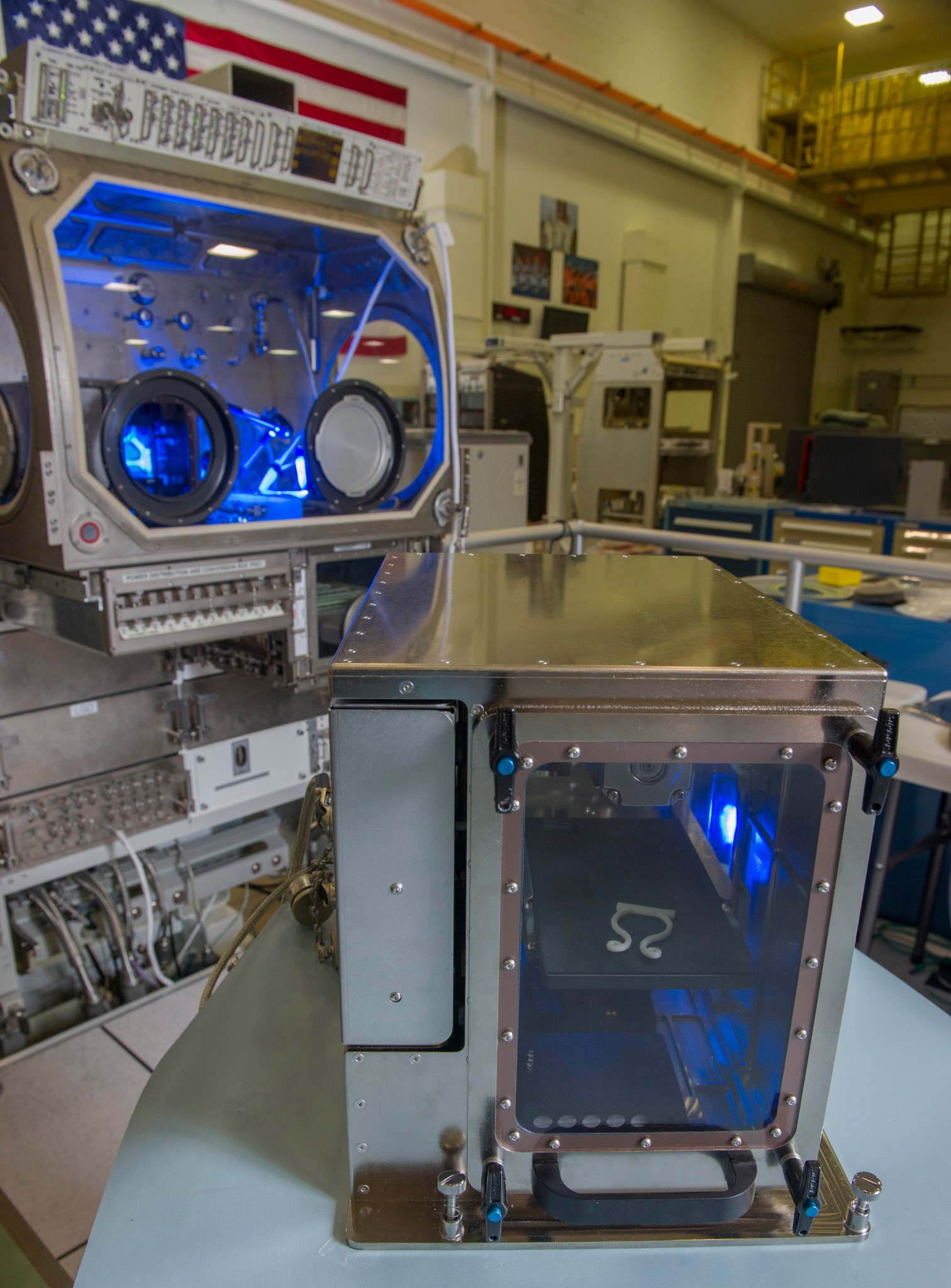

It may seem like an unbelievable feat, but NASA’s Marshall Space Flight Center awarded Made in Space a Phase III Small Business Innovation and Research Contract to develop, test and certify for flight the first mini-machine shop to perform 3-D printing in space.

The 3-D printing in Zero-G Experiment project, or 3-D Print for short, has been underway since October 2012. The resulting printer will fabricate small components and equipment on orbit and on demand.

“The greater the distance from Earth and the longer the mission duration, the more difficult it is to resupply materials,” said Niki Werkheiser, 3-D Print project manager in Marshall’s Technology Development & Transfer Office. “The space station is an ideal platform to begin changing the current model for resupply and repair to one that is more suitable for all exploration missions.”

The 3-D printer is about the size of a dorm microwave and uses extrusion-based additive manufacturing, building parts, objects and tools layer by layer out of plastic. Researchers hope to show a 3-D printer can work normally in space and produce parts equal in quality to those printed on the ground.

The initial parts to be printed are already loaded into the 3-D printer, but additional part designs will be added by uplinking new CAD files from the ground to the printer on orbit. The printer’s operations can also be controlled from the ground, including powering it on and off, as well as monitoring and controlling the printing process. Astronauts on board the International Space Station will set-up the printer and remove the completed part from the print tray when ready for use.

The printer can create parts about the size of large candy bar, between 2.3 inches (6 cms) by 4.7 inches (12 cms) by 2.3 inches (6 cms). However, with 3-D Printing, larger parts can be assembled by connecting individually printed parts together. Print time can range from 15 minutes to an hour depending on the size and complexity of the part being printed.

Marshall and Made in Space, Inc. worked closely together during the printer’s design process. NASA offered insight and guidance to the company during the development cycle to ensure that all flight requirements were met, which ultimately led to successfully passing the stringent flight certification tests without any major issues. Additionally, all of the environmental and qualification tests required for flight and safety certification were conducted at Marshall in several facilities.

“The technology to produce parts on demand in space offers unique design options that aren’t possible through traditional manufacturing methods, while offering cost-effective, high-precision manufacturing,” said Werkheiser. “Additive manufacturing limits the need to stockpile parts and may alleviate a lot of structural and geometrical constraints caused by launch loads and vehicle stowage requirements.”

“We also look forward to using this technology as an educational tool by partnering with the American Society of Mechanical Engineers Foundation to issue the Future Engineers. We will be offering students from grades K-12 the opportunity to design a part to be printed on the Space Station through the Future Engineers 3-D Printing in Space Challenge kicking off in September,” Werkheiser added.

The 3-D printer effort is a shared investment between NASA’s Human Exploration and Operations and the Space Technology Mission Directorates, which together seek to innovate, develop, test and fly hardware for use in NASA’s future missions.