6 min read

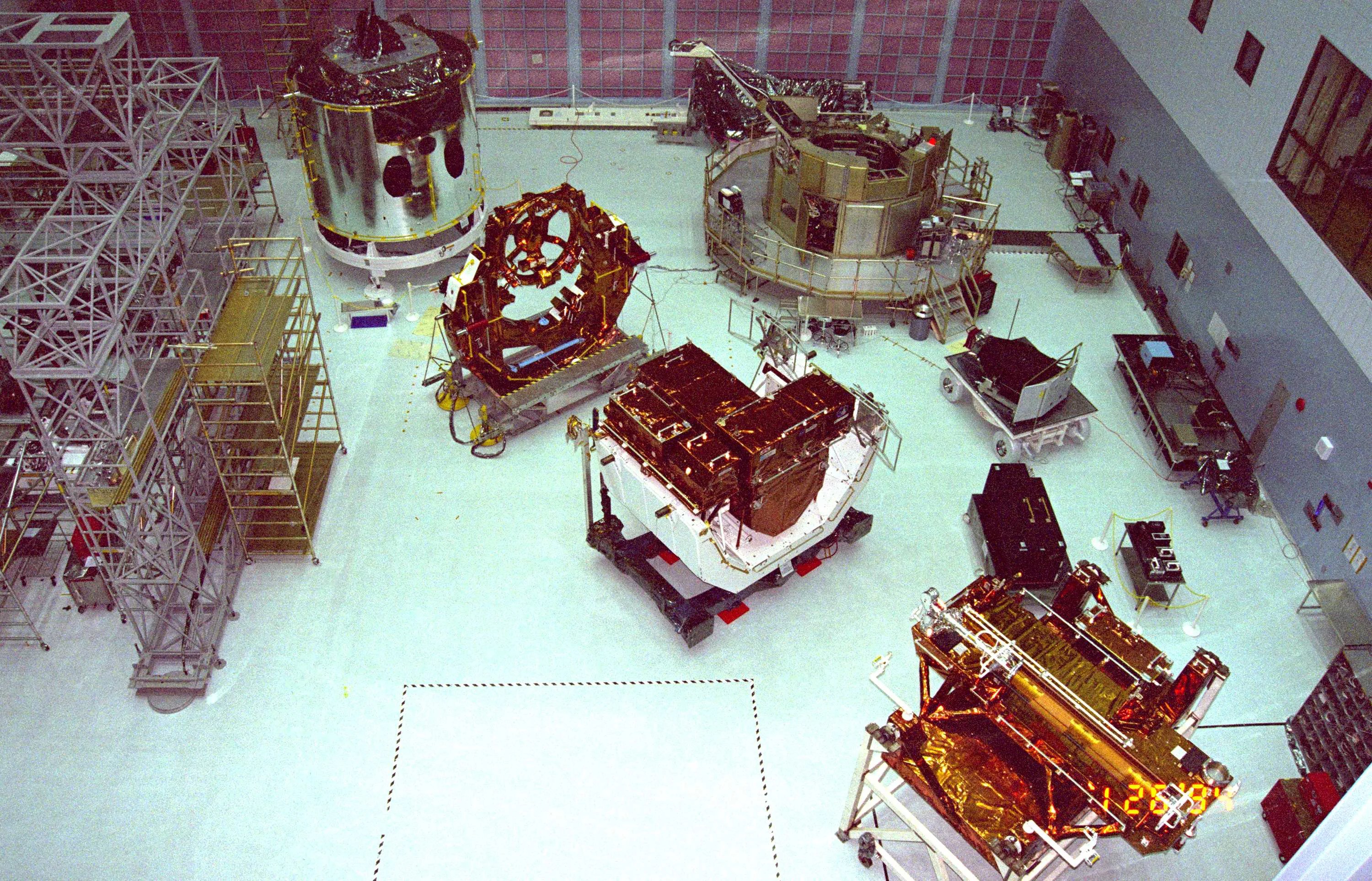

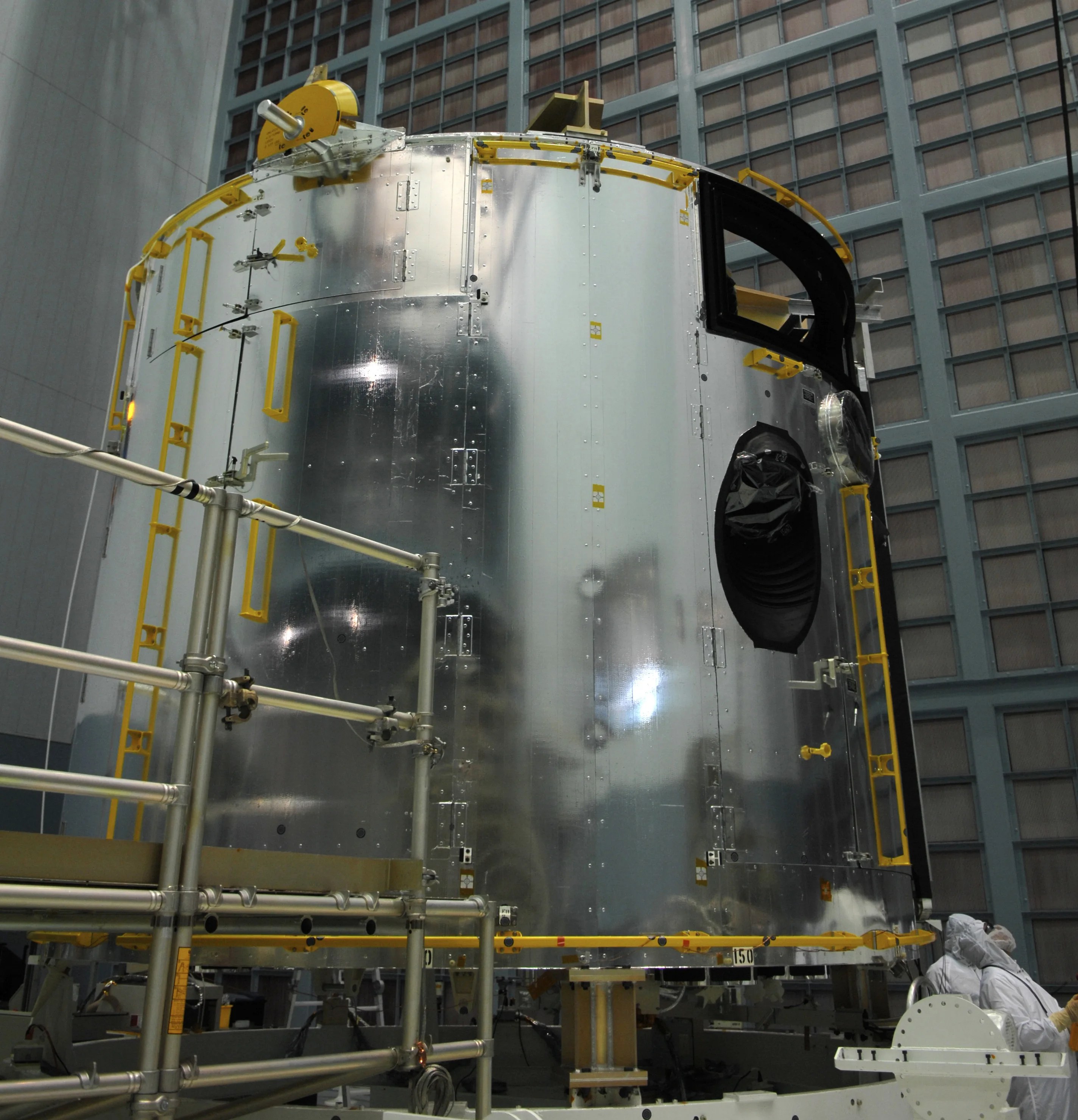

Astronauts will travel to the Hubble Space Telescope in 2009, installing new instruments and other components during Servicing Mission 4. But before these components are cleared for launch, they go through one final checkup in the world's largest clean room at NASA's Goddard Space Flight Center in Greenbelt, Md.

"The High Bay Clean Room is to Hubble what hospital operating rooms are to patients," says Mike Weiss, Hubble's technical deputy program manager at Goddard. "Surgeons wear sterile gowns, gloves and masks during surgery, and operating rooms must be kept free of germs to keep patients healthy. In our case, Hubble is the patient."

Before entering, workers pass through a set of "lobbies," all responsible for keeping the clean room clean. In the first lobby, or vestibule, as engineers call it, walking across the floor feels like walking inside a movie theater. But that sticky texture doesn't come from spilled soda. Adhesive floor mats trap loose dirt from employees' shoes.

The next stop is a small glass box a little larger than a phone booth where employees receive a forced-air shower. Dozens of air jets on the walls blow away loose debris from hair, skin and clothing. A green light indicates when it is safe to enter the last station, a larger area with lockers and benches. It is in this area where anyone intending to enter the clean room must don sterile bodysuits, head covers, gloves, boots and face masks, a painstaking process that can take upwards of 10 to 15 minutes.

Significance of the Clean Room

The clean room and the elaborate steps taken before entering it are vital to the success of every Hubble mission. Even a speck of dust or a fingerprint could severely damage the sensitive telescope components and instruments, so the clean room must filter out these harmful contaminants. Unlike personal digital cameras, a smudge or speck of dust on Hubble's optics and sensors can't be easily cleaned, especially once the instruments have reached orbit, Weiss says.

Besides being extremely clean, this facility is also the only place large enough to house Hubble's components and simulators, as well as all the equipment needed to prepare the components for launch. In fact, the Goddard clean room is big enough to house two space shuttle payloads at the same time.

Because of its size and sanitary conditions, Weiss says all the components taken to Hubble on the four previous servicing missions (SM1, SM2, SM3A and 3B) made their way through Goddard's clean room.

The Types of Contaminants

The entryway vestibules and suit-up process help counteract particulate debris, one of two contaminating offenders. Particulate debris includes tiny bits of dirt or dust workers might track in, such as loose fabric lint or flakes of dead skin. A robust ventilation system and an entire wall of air filters provide further protection.

The clean room ventilation system circulates almost one million cubic feet of air every minute through 9,000 square feet of HEPA filters located along one wall. The filters are not your typical off-the-shelf HEPA variety from the local home improvement store. These are specially designed to last several decades, Weiss says.

Combined, all these features afford the Goddard clean room a Class-10,000 rating. That means any cubic foot of air in the clean room has no more than 10,000 particles floating around in it larger than 0.5 microns.

How small is that? A micron is one-millionth of a meter, and typical "outside" air has millions of such particles. (A human hair is between 20 and 200 microns wide.) If an inch ballooned to the size of the Empire State Building, a 0.5-micron bit of dust would still be smaller than a penny on the sidewalk.

Molecular contaminants, the second offender, are a little more difficult to describe. Most people are familiar with "new car smell." Over time that smell fades away because molecules in the car's plastics and leather vaporize, or "boil off." Exposure to the heat of a summer day speeds up the process.

The optics and sensors inside Hubble and other spacecraft go through a similar process. Orbiting Earth every 97 minutes, Hubble passes through the intense heat of the sun a whopping 15 times a day. Those higher temperatures can cause materials inside Hubble to boil-off molecules.

The loss of some molecules poses no threat to a car, but this molecular damage can devastate sensitive optical equipment. To prevent this, all of Hubble's new components and instruments are put into a vacuum chamber and literally baked at high temperatures. This process eliminates potentially damaging molecules in one fell swoop, so they do not cause problems after the components are installed on Hubble.

Pre-Launch Testing

Because the Goddard clean room does an excellent job of filtering out contaminants, it is the perfect place to assemble and test Hubble's components. Technicians spend hours running system compatibility tests to make sure all of the telescope's new instrument electronics and software will work correctly, a key step in pre-flight preparations. Hubble's new instruments are connected to an exact duplicate, or simulator, of Hubble's electrical system, called the Vehicle Electrical System Test facility, or VEST.

Instruments also go through a mechanical test to ensure components will fit and operate properly once they are installed in the telescope. Engineers mount the instruments inside an exact mechanical replica of the telescope's optical end: the High Fidelity Mechanical Simulator, which was built from the same blueprints as Hubble. Using this simulator, astronauts have the opportunity to see how hardware will look like once installed on Hubble.

The clean room also contains a structure called the Flight Support System. When reconfigured for the Hubble mission, the FSS will provide structural, mechanical and electrical interfaces between Hubble and the space shuttle. It serves as a maintenance platform, holding Hubble securely in place as astronauts work on the telescope. After servicing is complete, the support system enables astronauts to safely return Hubble to its orbit.

Only after all ground testing is completed and fit checks are performed will Hubble's new instruments and components be carefully packed for shipment to NASA's Kennedy Space Center in Florida.

Next stop: the Hubble Space Telescope!

By Robert Garner

NASA's Goddard Space Flight Center, Greenbelt, Md.