NASA’s Commercial Crew Program

NASA’s Commercial Crew Program started the year by securing an additional four crew rotation missions from Boeing and SpaceX. The missions will carry astronauts to and from the International Space Station through 2024. The four additional missions fall under the Commercial Crew Transportation Capability contracts and bring the total number of crew rotation missions awarded to each provider to six. The missions will fly following NASA certification.

To meet NASA's requirements, the commercial providers must demonstrate that their systems are ready to begin regular flights to the space station. Two of those demonstrations are uncrewed flight tests, known as Orbital Flight Test for Boeing, and Demonstration Mission 1 for SpaceX. After the uncrewed flight tests, each company will carry out a flight test with crew prior to being certified by NASA for crew rotation missions.

NASA’s four astronauts training to fly the test flights on Boeing’s Starliner and SpaceX’s Crew Dragon spent time evaluating both providers’ progress during 2017. The astronauts are learning about the systems, being fitted for spacesuits and readying for flight tests to and from the International Space Station.

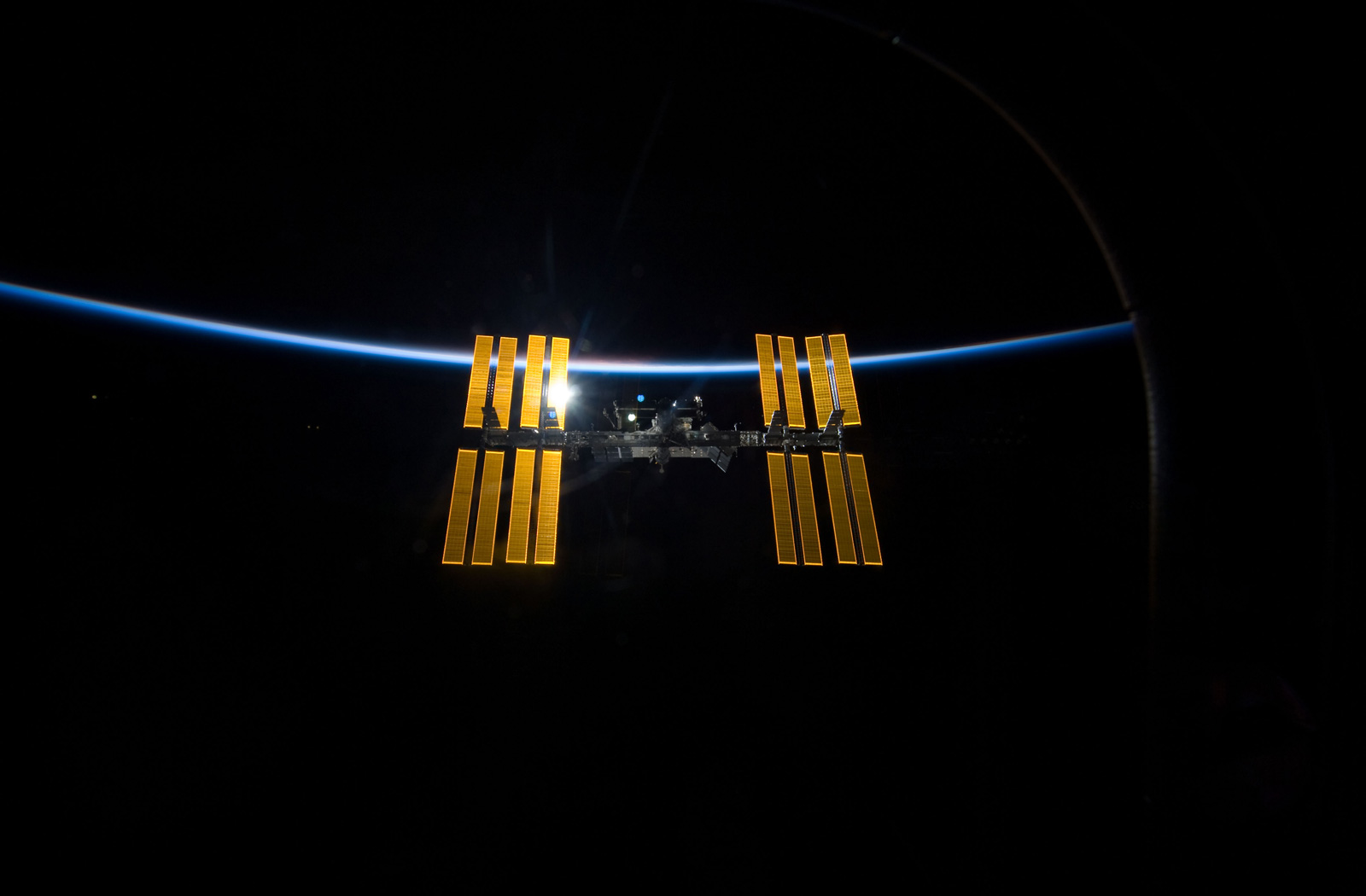

The International Space Station continued to prepare for the new commercial spacecraft to arrive. During Orbital ATK’s resupply mission to the space station in November, the cargo spacecraft maneuvered above the Harmony module prior to its release. There, it gathered data relevant to future rendezvous and docking operations for U.S. commercial crew vehicles that will be arriving for a linkup to Harmony’s international docking adapters. Other work included the space station crew installing and performing check-outs of a control panel on Harmony for the docking adapter.

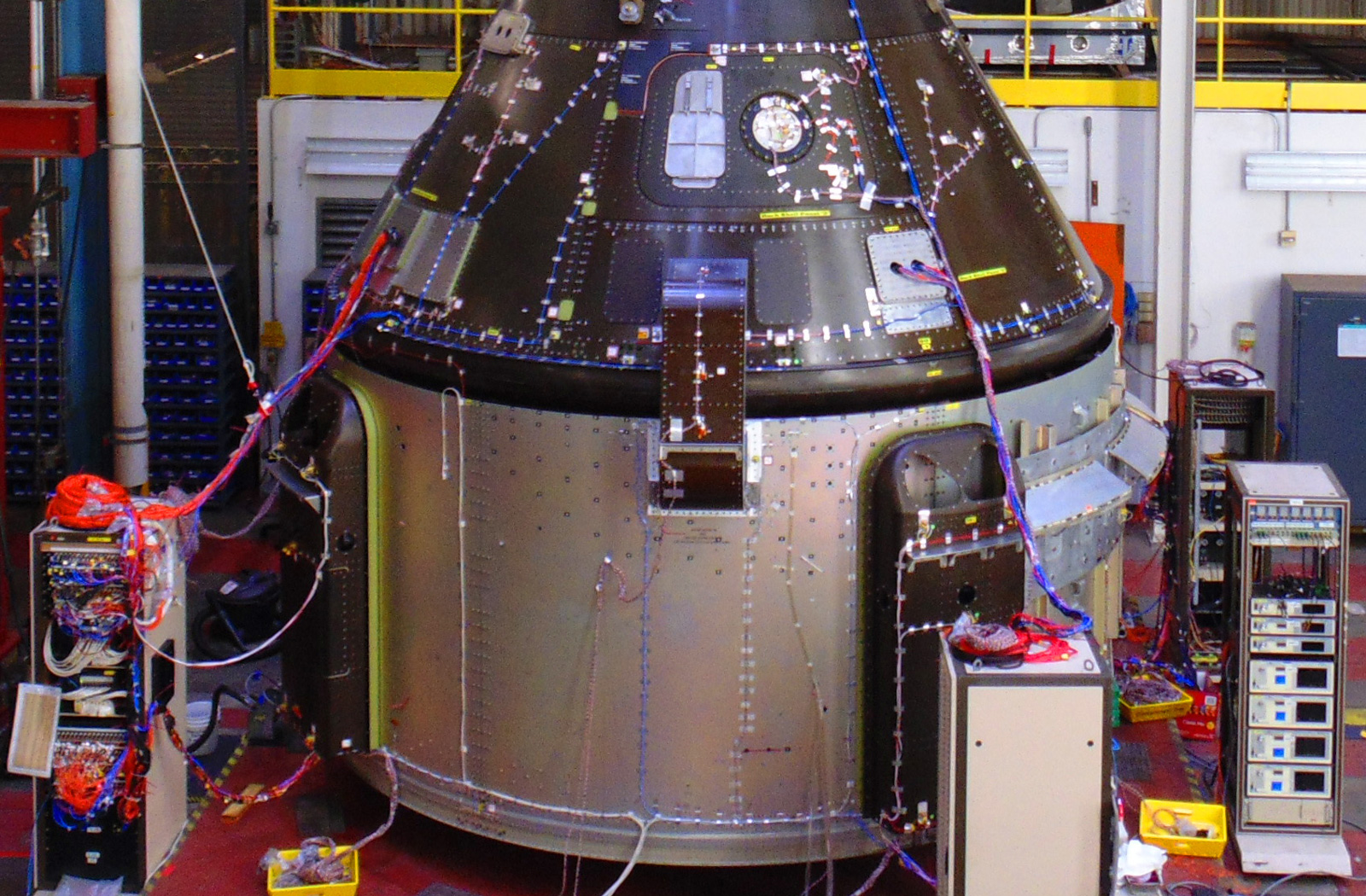

Boeing’s Starliner continued to be manufactured inside of the Commercial Crew and Cargo Processing Facility at NASA’s Kennedy Space Center in Florida. Three Starliners are in production inside the manufacturing facility.

This year, the Starliner was powered on for the first time, and test versions of the spacecraft have been shipped across the United States to be put through the extremes necessary to understand how the Starliner will perform in the space environment.

A Starliner Structural Test Article arrived at the company’s Huntington Beach Facility in California where the spacecraft, including the service module and other hardware of the Atlas V upper stage, are being put through rigorous qualification testing, including tests like shock, separation and vibration. Other tests are aimed at simulating the actual pressure that the Starliner will encounter during ascent, orbit and reentry to Earth’s atmosphere.

At the Landing and Impact Research Facility at NASA’s Langley Research Center in Virginia, a Starliner mock-up endured a series of land landing qualification tests designed to simulate a crew return to Earth in the Western United States. The test series verified that the vehicle would be stable in landing conditions. The capsule is designed for landing on land, making it reusable up to ten times with a six-month turnaround time between launches. Testing at Langley is complete with 14 tests performed.

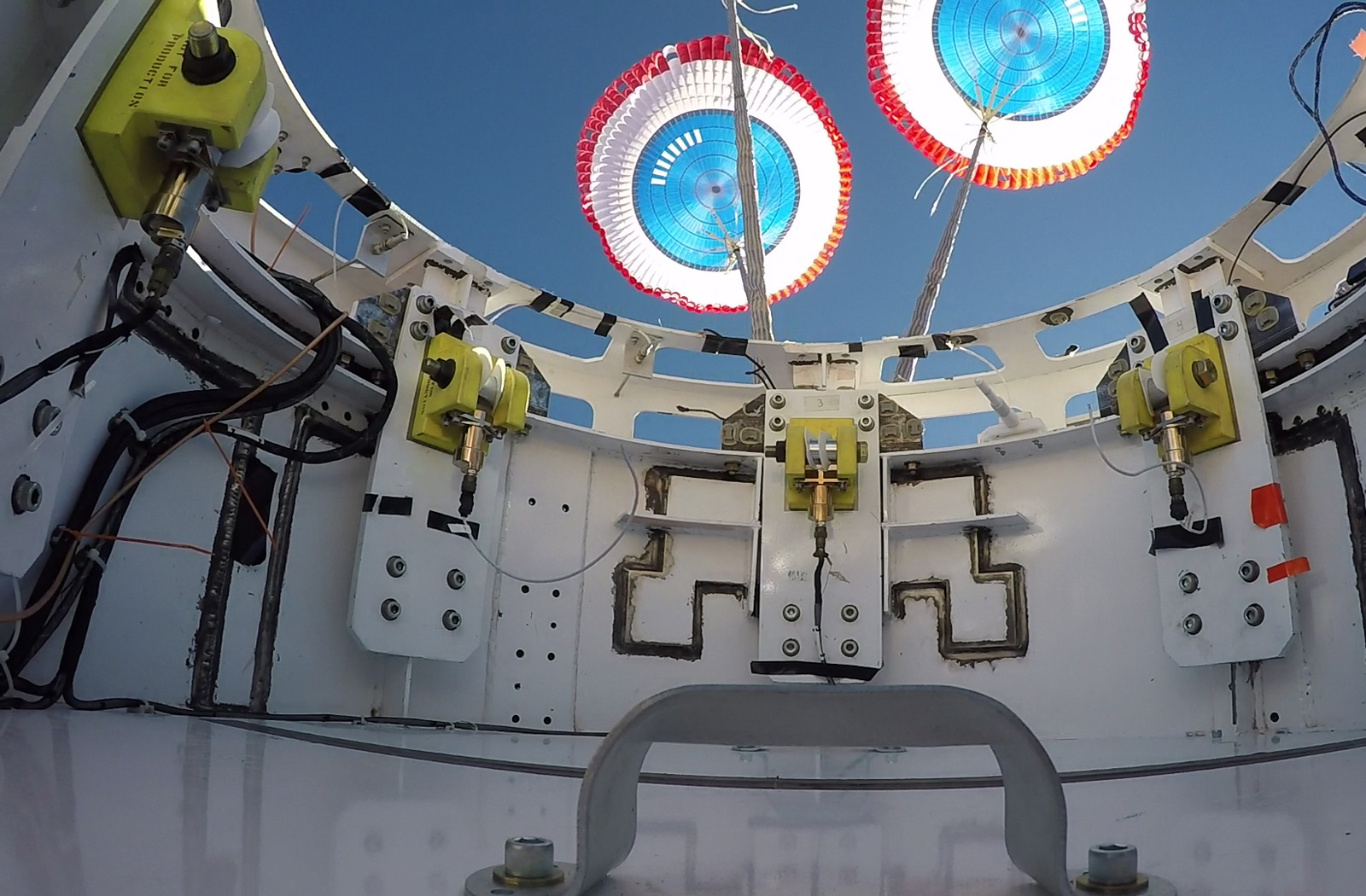

At the Spaceport America facility near the Army’s White Sands Missile Range in New Mexico, the Starliner went through a series of choreographed tests of its parachute and landing system, wherein the Starliner deployed its parachute systems to land safely on the ground. A large balloon lifted a flight-sized boilerplate of the Starliner to about 40,000 feet in the air. The test team then released the spacecraft to complete each test. Parachute testing will continue into 2018.

Boeing unveiled the company’s new, blue spacesuit astronauts will wear while aboard the Starliner. Designed to meet NASA’s safety and functionality requirements, the suit weighs about 20 pounds in total by using advanced materials, new joint patterns and zippers making the suit light and flexible. The suit has integrated boots, a soft helmet and visor connected to the suit and touch screen-sensitive gloves for using the onboard computers. For the astronauts’ comfort, the suit also aims to make the experience in the suit cooler through vents built into the suit while still allowing the suit to be pressurized if needed.

Boeing is developing the Starliner to fly on the United Launch Alliance Atlas V rocket from Space Launch Complex 41 on Cape Canaveral Air Force Station in Florida.

At the ULA facility in Decatur, Alabama, the company made progress on manufacturing the Atlas V that will launch Starliner for its uncrewed flight test in 2018.

An emergency exit system was installed and tested. The system will be available to astronauts and launch support personnel in the unlikely event of an emergency prior to liftoff. Each person on the Crew Access Tower would get into their own seat attached to the wire and slide more than 1,340 feet to a safe area. The wires are situated 172 feet above the pad deck on level 12 of the tower.

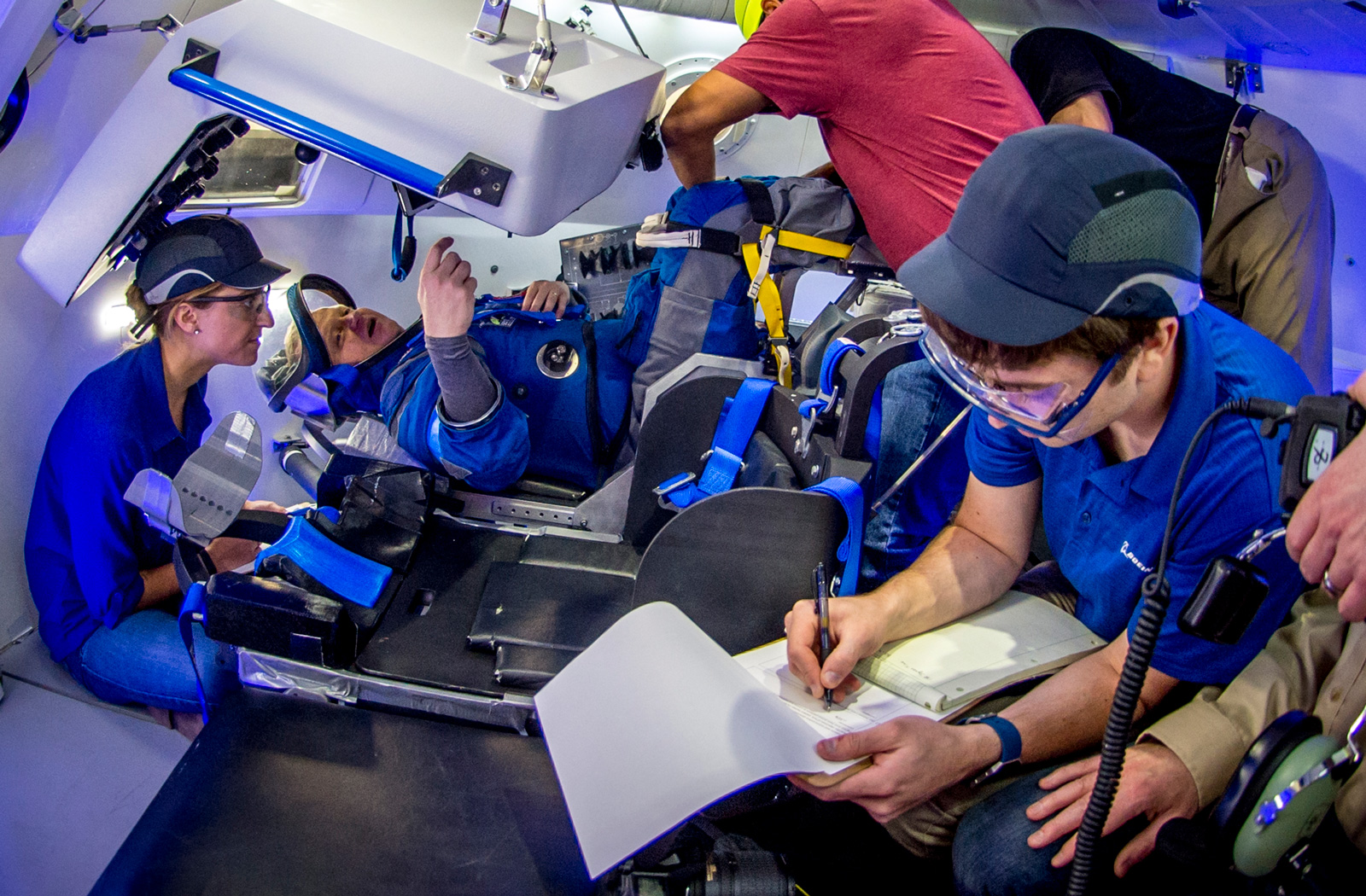

Engineers working with Boeing’s Starliner spacecraft lab tested their seat design focusing on how the spacecraft seats protect the head, neck and spine of the astronauts for the 240-mile descent from space. Test dummies also were incorporated inside Starliner during full-scale mock-up landing tests at Langley.

SpaceX is manufacturing the Crew Dragon spacecraft inside the company’s headquarters and manufacturing facility in Hawthorne, California. In total, SpaceX has six Crew Dragon modules in various stages of production and testing, including a qualification module, a life support system testing module, the two spacecraft for flight tests and the first two for fully operational missions. This year, SpaceX integrated the Crew Dragon capsule, performed acceptance testing, and powered up the avionics onboard the Demonstration Mission 1 module in preparation for the company’s uncrewed flight test. Further qualification testing and work on mechanical integration for Demonstration Mission 2, the crewed flight test, is ongoing.

Astronauts Bob Behnken and Eric Boe, two of NASA's four veteran astronauts who supported SpaceX as it refines its crew transportation system designs, checked out the Crew Dragon being used for qualification testing at Hawthorne. Behnken evaluated the Crew Dragon's hatches. The top hatch, at the nose of the spacecraft, will be the connecting port at the space station. The side hatch will be the entryway for crews getting into the spacecraft when on Earth.

Behnken and Boe also evaluated the controls, seating and other aspects of the crew compartment of a mock-up of SpaceX's Crew Dragon spacecraft during a visit to the company's headquarters in Hawthorne. The astronauts studied many aspects of the crew compartment's layout, including spacing of displays and ease of movement. SpaceX has continued to mature displays and controls, crew interfaces and operations.

SpaceX built a test version of its Crew Dragon solely for evaluation of the life support system that will provide tight control of parameters that are important to human safety such as temperature, carbon dioxide levels, oxygen levels and cabin pressure. The environmental control and life support system (ECLSS) was extensively tested and evaluated at the company's headquarters in Hawthorne.

SpaceX, NASA and U.S. Air Force personnel completed full-scale joint recovery trainer exercises to prepare for and ensure crew safety in the unlikely event of a rescue scenario. A full-size model of the spacecraft was used during rescue training. The Rescue Trainer was lowered into the Indian River Lagoon near NASA's Kennedy Space Center so that Air Force pararescuers and others could learn techniques for quickly reaching the spacecraft and supporting the astronauts onboard. SpaceX followed up the rescue and recovery testing in the Atlantic Ocean with spacesuit-clad astronauts and personnel who will assist upon return to Earth. The company will continue these training exercises in 2018.

SpaceX unveiled the first look at its new spacesuit design that astronauts flying to and from the International Space Station will wear inside the Crew Dragon spacecraft. Suit testing is underway to ensure the suit performs as designed. NASA astronauts have been doing spacesuit fit checks and other testing to prepare for missions, including the first pressurized spacesuit tests using NASA astronauts.

In February, SpaceX hosted its inaugural flight from historic Launch Complex 39A at NASA’s Kennedy Space Center in Florida. In addition to performing water deluge sound suppression tests, multiple Human-in-the-Loop and software simulations, and completing structural upgrades at the site, the company has successfully launched 12 missions from 39A in 2017 providing insight into the pad for commercial crew missions.

The company’s Crew Access Arm will be installed on the launch pad and provide a bridge between the crew access tower and SpaceX's Crew Dragon spacecraft for astronauts flying to the space station on the company's Falcon 9 rocket. The access arm will be installed in early 2018.

NASA’s Commercial Crew Program continued work with Blue Origin and Sierra Nevada Corporation in 2017 to develop and refine their respective spacecraft and launch systems. Under these agreements, NASA provides expertise and insight into their spaceflight designs.

Sierra Nevada Corporation's Dream Chaser spacecraft completed a series of tests at NASA’s Armstrong Flight Research Center located on Edwards Air Force Base in California. The testing culminated with a free flight test where the uncrewed spacecraft was lifted about 12,400 feet into the air by a helicopter and then released for a successful approach and landing, leading to the completion of a major milestone under a Space Act Agreement with NASA's Commercial Crew Program. The tests helped Sierra Nevada Corp. validate the aerodynamic properties, flight software and control system performance of the Dream Chaser under the Commercial Crew Integrated Capability Space Act Agreement, or CCiCap.