If you’re fascinated by the idea of humans traveling through space and curious about how that all works, you’ve come to the right place.

“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center from Houston, Texas, home for NASA’s astronauts and Mission Control Center. Listen to the brightest minds of America’s space agency – astronauts, engineers, scientists and program leaders – discuss exciting topics in engineering, science and technology, sharing their personal stories and expertise on every aspect of human spaceflight. Learn more about how the work being done will help send humans forward to the Moon and on to Mars in the Artemis program.

For Episode 118 Tara Jochim and Brian Mader talk about a unique and difficult set of spacewalks to repair an experiment called the Alpha Magnetic Spectrometer. The two discuss the work that has been done so far to prepare for these spacewalks and what the teams will be doing to execute these complicated maneuvers. This episode was recorded on October 9th, 2019.

Transcript

Gary Jordan (Host):Houston, we have a podcast. Welcome to the official podcast of the NASA Johnson Space Center, Episode 118, “Alpha Magnetic Spectrometer, The Spacewalks.” I’m Gary Jordan. I’ll be your host today. On this podcast, we bring in the experts, scientists, engineers, astronauts, all to let you know what’s going on in the world of human spaceflight. Coming up very soon, this November 2019, astronauts aboard the International Space Station are set to kick off a unique and difficult set of spacewalks to repair an experiment called the Alpha Magnetic Spectrometer. Sounds like something straight out of sci-fi, right? But it’s very real, and a very complicated piece of equipment. The Alpha Magnetic Spectrometer, or AMS, is collecting data from high energy particles and looking for evidence of antimatter and dark matter in the cosmos, which may reveal more about the formation of the universe. Now, with such a complicated particle physics experiment, comes some complicated spacewalks, where astronauts get in their spacesuits and go outside of a spacecraft, and in this case, for the International Space Station, to go through a well-thought-out and planned procedures with special tools to fix things. So, to help bring to light the significance of this experiment and these spacewalks, we’re going to dive deep into the story of the AMS and this repair, and break this into three parts: the science, the spacewalks, and the tools, all with fascinating discussions with the experts that are working on repairing the AMS. So, last episode, we sat down with Brandon Reddell, and he walked us through the astrophysics and cosmology of it all, and what this Alpha Magnetic Spectrometer is all about. So, today, in part two of this three-part series, we’re going to focus on this complicated series of spacewalks with the very people who are leading the effort, Tara Jochim and Brian Mader. Tara is the Project Manager, and Brian is the Task Lead for this repair mission. And they walk us through all of the work that’s been done so far to prepare for these spacewalks, and what the teams will be doing to execute these complicated maneuvers. So, here we go. The history and details behind the Alpha Magnetic Spectrometer spacewalks, with Tara Jochim and Brian Mader. Enjoy.

[ Music ]

Host: Tara and Brian, thank you so much for coming on the podcast today.

Tara Jochim: Thanks for having us.

Host: Alright. Tara, welcome back to the podcast. I think it was episode 83, we talked about planning for, I’ll say with quotes, “A regular EVA.”[Extravehicular Activity] But now you’ve been — actually even at the time, I believe, when we were talking about planning for a normal EVA in episode 83, you were working on these spacewalks.

Tara Jochim: That’s right. It’s been a long haul here. Four years we’ve been working to develop and design and really train for these EVAs. It’s been a great road.

Host: That’s right. Now, your role specifically is what for these particular spacewalks?

Tara Jochim: I’m the Space Station Program Project Manager for the AMS EVA Repair activities. So.

Host: OK.

Tara Jochim: It’s a mouthful. I herd a lot of cats, and get everybody where they need to be hopefully. You know we set up the requirements way back in the beginning, almost four years ago, on how we were going to go about doing this. I helped the team then figure out how we’re going to get there, get them the funding to do it, and make sure in the end we’ve met all the requirements and everyone’s going to be safe to go off and do their activity. So.

Host: OK, so it’s defining those requirements and then making sure — herding the sheep and making sure everyone’s following along, right on time, keeping that timeline going.

Tara Jochim: Right.

Host: OK. Brian, welcome to the podcast.

Brian Mader: Thank you.

Host: Your role is Task Lead?

Brian Mader: Yes.

Host: So, what do you do as Task Lead?

Brian Mader: So, my job title, I’m the EVA Task Lead. EVA is Extra Vehicular Operations Spacewalks. So, in general, what I’m responsible for is training astronauts to do their spacewalks, and then developing the procedures for the spacewalks. And when we’re actually doing them in space, I’ll be in the Mission Control Center, in one of the back room, support rooms. So, the MPSR’s are Multi — what is it? Multi-Purpose Support Room. There we go. [Laughter]

Host: Anytime you can pull out the actual long form of an acronym, it’s pretty impressive, because there’s so many. You learn stuff every single time we do this podcast. But your job I guess, in the back room, would be, and correct me if I’m wrong, to know those procedures backwards and forwards?

Brian Mader: Yeah, yeah. So, for normal EVAs, we don’t have as long of a lead time. We’ll probably talk about that later, but for these, like Tara said, four years in the making. We’ve gone through all the hardware development, just from the phases of what tools do we even need. And then, OK, we figured out what tools we need. How do we make those usable for somebody in a spacesuit? So.

Host: OK. That’s kind of where I wanted to start with this one, because Tara, like I mentioned, we talked about generally planning for a spacewalk and how I wanted to start was comparing that. Comparing what we would say as just a normal spacewalk. Let’s take for example, the battery spacewalks that we have going on right now, which we’ve done in the past. We have the tools. And then the differences with what it takes to plan for these AMS EVAs.

Tara Jochim: Well, I think one of the big things is what we consider these different types of EVAs. And a normal EVA, I think is what we’ve been calling it is more of a skills-based training event that the crews go through. They’re given a series of different training activities and they learn, kind of generically, how to do EVA. And they’re able to go on orbit and perform more of these more generic skillsets. And for the AMS EVAs, things are rather different than that. We have a lot of specialized tools that were built specifically for AMS. We incorporate our more generic EVA tools as well, but these specific tools, they had to receive a lot of training on, and be able to understand the specific tasks that they have to do, which again, are very unique to AMS. So, I think those are the big differences. Brian, if you have any other thoughts on that one?

Host: So, what if you — if you’re going through your normal training, what does that look like? What does normal EVA training look like?

Brian Mader: So, as Tara said, we do a skills-based training. So, for an astronaut that is assigned to fly to space station, they have about a year and a half of a training plan. And we have — it’s about eight neutral buoyancy lab runs, where they get in the suit, get in the pool, and they go through generic tasks. So, those are focused largely on what we call the Critical Contingency EVAs, or CCEs. So, critical station systems that if one breaks, we have to get outside and fix it pretty quickly. But again, skills-based, so they focus on generic tools and things like how to get around station. Not necessarily how do you put certain tasks together in a spacewalk.

Host: But if you’re going to practice a run of any kind of task, it’s going to be your emergency tasks, because you want to know if something goes wrong, you at least know the basis of how to work with that issue.

Brian Mader: Sure, and we do reserve the last — it’s usually in about the last two runs of their training flow where if we have an idea that maybe this particular crew is going to do a spacewalk, we would put that content in there. So, for AMS, we’ve known for a long time, you know, these are much different than that skills-based, so we wanted to get a lot of specific training for the crew.

Host: OK, so we’ll get into that. We’ll get into that in a second, but I did want to go through — so, we talked about training tools. What are the normal tools that they would be using?

Tara Jochim: For the AMS EVAs, we’ve got — I wouldn’t call them normal. I would call them unique, right? We went through and had to figure out what these specific tasks were going to be for EVA. So, a lot of the unique tools are involved with cutting some stainless-steel tubes. Really thin tubing that is located on the AMS itself. We have to be able to go in and bypass a system that’s there, and install a new system in place of it. So, you have to be able to hook up this stainless-steel tubing. We don’t like to cut things in orbit, in a spacesuit. You know, you’re going to generate a sharp edge or maybe some debris. So, those are considerations we had to take as we went off and designed these different tools, the engineers, you know, the smart EVA engineers that have designed tools for a long time, had to say, “Well, this — this is going to be a unique place that we’re going to be at, this worksite. A unique skill that’s going to need to be done, and how can we make it safe for the EVA crew member throughout the process?” So, some new cutting tools, some new swaging tools, and just some unique EVA handrails and things that we didn’t have in the past, have to be installed in this location.

Host: OK, so like, I guess you would say, tools for — for example, the battery spacewalks. They’re not as you know, you don’t have to deal with those sharp edges. It’s — and like you said Brian, they’re learning kind of the basic skills with these tools when they at least first start training to learn how to do an EVA in the first place.

Brian Mader: Sure. So, for example, when a new astronaut comes in and they’re first starting their training in the pool, you know, it’s learning how to maneuver in the suit. So, it’s not easy just being in the suit. But then talking about generic tools, one of the most basic tools that we use is a tether. So, everything in space has to be tethered at all times, otherwise, it floats away, and that’s not fun. Especially if it’s you. So, the crew members have tethers, right? And they’ve got a safety tether. They’ve got other tethers that they use to hold themselves at a worksite. And then every piece of equipment is tethered. So, you know, imagine drinking your coffee in the morning and having a rope going to it, and then you have to move it to another one. It’s very time-consuming. And it can also be — you know, they take tennis balls to do hand exercises, right?

Host: Oh, wow.

Brian Mader: Because it’s very forearm intensive. The suit is pressurized at 4.3 psi, so anytime you clench your hands, make a fist, you’re fighting against that pressure. So, just being outside is physically draining in that regard, too.

Host: Very true. Yes, spacewalking 101, attach yourself to all things, and attach all things to yourself. So, that — yes, you don’t want any kind of free-floating things. So, that’s spacewalking 101. And then spacewalking skills 101, get that grip strength going.

Brian Mader: Yeah.

Host: Yeah. That’s a good one.

Tara Jochim: Yes, and some of the other stuff, you know, you talk about these battery EVAs that were going in right now, and they are a little bit more skills-based, right? They have these generic EVA worksites that were designed for the EVA crew member to be there. They are protected from a safety perspective of being able to withstand a crew kicking or bumping that location. In theory, they’re not sharp. You know, they’ve been protected from that on the ground. And they have handrails in those locations so to allow the crew member to stabilize themselves in that worksite. We don’t have any of that for AMS. So, going in and looking at these, what we determine to be worksites, we had to go make them so that they were EVA-able. We installed handrails in locations where they are none. Certainly no brackets or they weren’t locations that were built for an EVA handrail to be installed on, so the engineers here had to go off and design new handrails for an EVA crew member to be able to go and install them. So, simple things like that. You have to set up the worksite. If you’re at home working on your car, you have to have a workspace for yourself to work in. Well, we had to go off and design that on a piece of hardware that’s in space. So, you only have the drawings that you have on the ground, the recollections from the engineers that were the ones that built it and designed it in the first place, many years ago. And then you go off and do your best effort to figure out, how is this new piece of hardware that we’re going to just — going to design, fit with the item that’s in space?

Host: So, naturally, this is where those four years of planning come in, because you’re working with something that A, wasn’t really meant to be worked on, so you have to design a way to work with it. And then not only that, but you don’t really get to play with it a little bit. You have to — that’s a lot of guesswork, but I guess educated guesswork, because you said you’re looking at drawings, you’re talking to experts, it’s just not the real thing.

Tara Jochim: Right, very educated guesswork. I would call it. [Laughter]

Host: Yeah, for sure. This is a sensitive piece of equipment which I think is part of the reason why you’re developing the techniques and tools the way that you’re doing is because like you said, you mentioned the part of the battery spacewalks that they’re doing, you know, if crew members can bump up against some things, this is not a piece of equipment you really want to bump up against. So, I’m sure you’re designing, not only tools and — but also techniques to really help you to deal with that.

Brian Mader: Sure, so, you know, one of the things that we put into a lot of those runs in the pool, and we also used ARGOS, [Active Response Gravity Offload System] which you guys are familiar with.

Host: Oh, yeah. I was there. I got to check it out.

Brian Mader: Yes. So, we’ve used ARGOS to train the crew a lot. You know, the spacesuit takes up a lot of space, just in and of itself. And we’re trying to get into very small areas, as Tara said, that weren’t designed for EVA. There’s also things — I mean, this is a big particle physics experiment. So, there’s tons and tons of wires and cables and some of them were used for ground testing and they’re not that important anymore. If we happen to cut or rip one of those, it’s not that big of a deal. But, there are other ones that are critical to the experiment, where if we cut certain cables, there’s one that we’re going to be very close to for a lot of the work that we’re doing, have nicknamed the aorta of AMS because it’s a main data channel for a lot of the experiment.

Host: Wow.

Brian Mader: So, we’ve got to be really careful with that one.

Host: So, I guess a lot of designing this spacewalk was trying to figure out how this thing works, and knowing all the ins and outs of it so that you’re cutting the — you’re cutting the right wires.

Brian Mader: I’m no particle physicist, I’ll say that.

Tara Jochim: Yes. You know, somewhat, yes. We had to understand what those pieces and parts are that you know, the crew members going to be interfacing with, but that’s where you also bring in the experts. We’re fortunate that we have the AMS Project Office here in Houston, and it has worked with the engineers and the physicists over in Europe for a number of years, and helped design and build the AMS itself. Having that knowledge here at JSC has been just super, super helpful to us to be able to go off and design this. To help you know, build the mockup for us to be able to go off and use in these training events, and really are tool design events I would call them, in the beginning. And their innate knowledge from that is what helped us be able to go figure out the exact worksite that they wanted to be in. When we first, Brian I’m sure you remember, when we first started this, many years ago, we were actually in a different location on AMS itself. And once the smart EVA folks got together with the smart engineers that knew about AMS itself. We determined that was not going to be the best location for an EVA crew member to access what we needed to get to, so they went back with the folks at CERN, [Center European Research Nuclear, Geneva Switzerland], and really determined another location. “OK, this new location will also give us this access. Would this work from an EVA perspective?” So, Brian’s team went off and they figured out what was going to be the best way to access that, and we went running from there. Here we go. Here we are.

Host: Yeah, here we go. I know you said the — you’re working with teams that are sort of local. You also have to work with teams kind of all over. Did you pull some — I’m trying to think of like another scenario. The one that comes to mind naturally is Hubble. Was there knowledge pulled from those servicing missions?

Tara Jochim:Absolutely, yeah.

Brian Mader: So, a lot of the fasteners, so we’ve got to remove a lot of fasteners that are just normal fasteners you’d have, maybe not at home but on hardware on the ground, that are not EVA compatible. So, for bolts that we plan to remove during the spacewalk, it has to be captive, right? We don’t want it floating away. So, they’re generally spring-loaded. They’ve got a clip or some other means to keep the bolt captive, even when it’s released from the hardware that you’re using. So, for this hardware, none of that was built in place because they didn’t intend to do it, right? That was one of the things that was, I think I can say, a large part of the work on Hubble where they removed a lot of fasteners. And some of them even, tiny, tiny fasteners. So, we’re able to leverage that and use, we call them Hubble Heritage tools to capture these fasteners. So, they’ve got basically a bit with a fork at the end that you’re able to scoop under the head of the fastener, and under the washer, and actually capture that fastener as you’re backing it out of the hardware.

Host: See, it is details like that, that I find absolutely fascinating, because you just hear like, “Oh, it was meant to — it was — you know, you were meant to service this on a spacewalk.” Like batteries, right? Everything is kind of designed so if human hands were meant to go service it. But when you get into the details of why this was not designed to be serviceable, it gets really complicated, because you’re talking about these tiny, little things that can float out. Not only very tiny and hard to work with, but you’ve got to do it in this bulky suit with these bulky gloves. Now, that’s where I guess the challenges come for you guys.

Brian Mader: For sure.

Tara Jochim: Yeah, and you asked some of the other differences with Hubble, what I would focus on from a program perspective is shuttle — or I should say Hubble, had individual shuttle missions, designated. You know, this is what we are going to do. We are launching this shuttle mission so that we can go up and repair Hubble. They had a whole army of folks behind them, and a rather larger bucket of cash to pull from to be able to go off and design all these great new tools and events, training, all these things that they needed. From a space station perspective, we have a lot of other priorities going on right now. You know, at space station, we live and breathe and work in space every day of the year, and so we had to balance those priorities with the priority of going off and being able to repair the AMS. So, our group of folks was much smaller that we were able to leverage against this problem that we saw in front of us, and our bucket of money was smaller. So, it was a real challenge from the team perspective of really looking at this differently, and saying, “How can we go about this safely, with a high opportunity for mission success, and to be able to repair this item and really, you know, increase our knowledge of physics for years to come?”

Host: Yeah.

Tara Jochim: So, it’s been a really unique challenge for the entire community.

Host: Resource-wise, staffing-wise, definitely those constraints. Also, like you mentioned, I mean this is on the International Space Station. I guess the difference with the shuttle going to Hubble is that that was it. It was shuttle going to Hubble. This thing, there’s a lot of other things happening on board the space station. The crew is busy. There’s launches and landings happening all the time. So, not only you know, finding the — your limited resources to work with this, but finding the opportunity, the timeframe, where you can actually do it. That’s got to be challenging as well.

Tara Jochim: Yeah. The planners certainly have a big challenge ahead of them with these next, you know, series of battery EVAs and like you mentioned, all the comings and goings to station. And all the other great science that station is doing as well. So, it’s a balance, right?

Host: Yeah.

Tara Jochim: It’s a balancing act to be able to fit all these things into the limited number of hours in the day, besides the fact that the crew, they live there, right? They have to eat. They have to exercise. They have to take care of business on station. So, it’s just like being at home here. We all have things we have to do at home. You have to balance that workload.

Host: That’s right.

Tara Jochim: They’re doing a great job so far. We’re really looking forward to seeing the schedule in the coming weeks.

Host: Well, let’s rewind the clocks a little bit. Let’s go back to, you mentioned four years. You mentioned four years that you’ve been working on it. Take me back to the beginning when this first became something that we started talking about. “We’re going to look at repairing the Alpha Magnetic Spectrometer.”

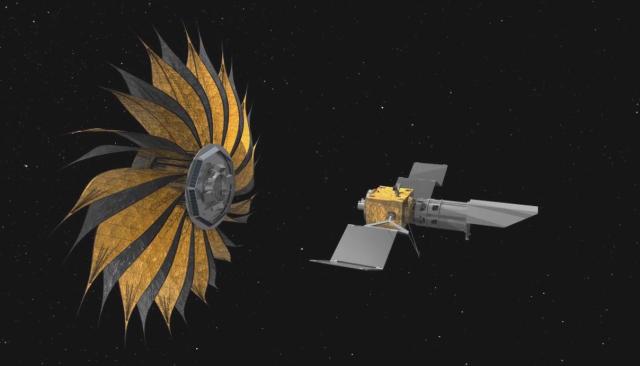

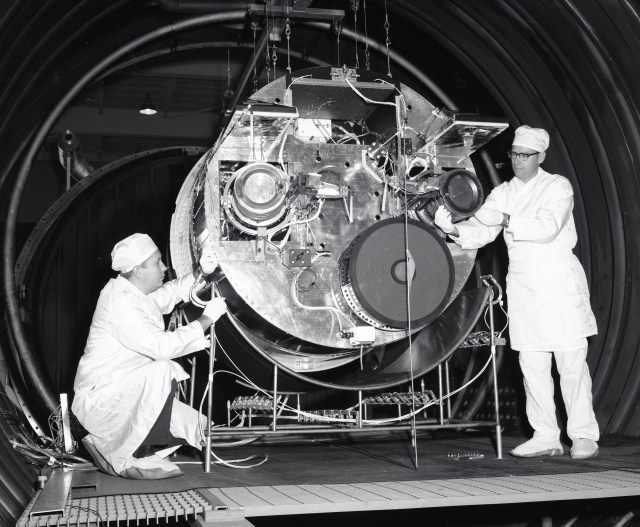

Brian Mader: So, you might remember, it was about four years ago, we did a spacewalk where part of that was we installed a big blanket on AMS. So, they were having difficulty with thermal conditions at that time, and the blanket was kind of their first step in troubleshooting. They thought it was just something in how the system was designed. Something they didn’t anticipate. So, we did that. We installed a blanket on the whole port-facing side of AMS. And we also installed a smaller — we called it a tent, put a little tent blanket over a very small radiator, probably about the size of a — like a lunch bag, I’d say. And it was very soon after that where the AMS folks were looking at their data still. And quickly realizing that that wasn’t accomplishing what they thought it was going to. And they realized they had a bigger problem, at that point. So, they started looking into it, and it was really on the heels of that spacewalk when we kicked off all these discussions to replace the whole cooling system.

Host: So, that’s what was wrong, was the cooling system?

Brian Mader: Mmhmm.

Tara Jochim: Yes, there’s a series of four pumps that are on two different channels in the cooling system there, and the pumps were having issues. Started failing, pretty much one at a time. Serially, as they would start the new pump up, one pump runs at a time, and a pump would run for a while, and it would see some issues. Eventually, three of the four pumps have failed, and really, the fourth pump is on its last legs. They run it occasionally. They’re able to get science when the pump is running. The system is being cooled. So, we’re hopeful to go and bypass that old system. We cut into the old system, and install a new system on top of it, and then we’ll provide them four new pumps to last them the life of space station.

Host: OK.

Tara Jochim:So we have a lot more science out there still.

Host: Yes. And that’s kind of a key driver of this, right? I think, if I’m not — if I’m not mistaken, AMS was designed for a three-year lifespan. However, it’s getting some really valuable science, and people recognize that, and want to continue that. So, this work is really to extend the life and keep that science going.

Tara Jochim: Right.

Host: We want to keep collecting the data.

Tara Jochim: Right.

Host: And it’s your guys’ job to do that.

Brian Mader: No pressure. [Laughter]

Host: No pressure. OK, so let’s get into the nitty-gritty of the Alpha Magnetic Spectrometer and why it’s a bit more complicated. So, you started kicking off — you know, you realized there was this issue four years ago. The pumps aren’t working. OK, where do we start? What is wrong? How are we going to fix this thing? What were some of the first things you were doing?

Tara Jochim: First we gathered the team. And then we got the EVA experts. Brian was a part of the blanket install, so he came onboard. And of course, the AMS Project Office that built and designed, you know, was in support of that whole side of things to get it launched on the shuttle. We brought in safety and tools engineers that had built tools in the past, and are real familiar with EVA, and we just kind of started brainstorming with that team, and really looking at the wooden mockup, a very vague structure that we had of AMS. And a lot of PowerPoint presentations and things. And really just started brainstorming ideas on how we were going to go about — what is it that we needed to do, and then how we would approach it from an EVA perspective.

Host: That’s interesting. What is the EVA — the EVA perspective is, I guess I’m trying to think of the elements that would happen. What tools do you need? How much time do you need? What angles are going to be the best to, not only I guess, reach what you want to reach, but then not bump anything along the way. These are all things that you’re considering.

Brian Mader: What can you hold onto? What can’t you hold onto?

Host: Yeah.

Brian Mader: Yes.

Host: OK so–.

Tara Jochim: You know, I think how we’re going to get there? Are you approaching the worksite robotically? Are they climbing on the hardware that’s next to AMS? Can we install a foot restraint somewhere near it to get the crew member to where they need to be? So, it was, you know, much broader than just the EVA operations community. They had to bring in robotics and other folks. So, there was a lot of people to talk to, and then just starting to identify our requirements, and how we’re — what was the base tools that we needed to build? And some of the first ones were, we have to install handrails. We know we’re going to remove all these non-captive fasteners that Brian was talking about. Then we brought Goddard in to help. And then where are these handrails going to go? What would be the best location for that crew to approach this worksite?

Host: OK. Yeah, that’s got to be one of the top things, is actually getting there.

Tara Jochim: Seems simple, right? Well, of course. You just go to the worksite. Well, usually our EVA worksites are already designed for us, and were tested on the ground and launched. This time around, we had to do all that work with the hardware on orbit, and create it together.

Host: OK so, I guess number one would be access. You want access to the AMS. You want ways that you can actually reach what you want to reach. So, naturally handrails would be one of those things, and a handrail, I guess is just — is just something you grab onto and it doesn’t pull anything, or you know, affect anything when you’re grabbing onto it.

Tara Jochim: That’s right.

Host: That’s number one.

Tara Jochim: It’s got to meet all the loads underneath, right?

Host: Oh.

Tara Jochim: You can’t just stick a handrail on any old piece of hardware. It has to be able to sustain the loads that a suited, or massive EVA crew member can impart into that structure below it. So, you don’t want them ripping the handrail off the side of AMS. That would be bad. So, the AMS engineers had to help with that in identifying those locations of where we could put the handrail. And then Brian’s team had to go off and say, “You know what? That’s great but we actually need it over in this location, because that’s where the crew is going to be from a worksite perspective.” So, then the tools engineers would go off and figure out, “Well, we see the structure that’s available to us. How can we create an interface that meets all the learning concerns, and allows the crew member to be able to handle the item itself?”

Host: See, right there. That’s where it gets super complicated, right? Because you have a need, right Brian? You want to — your need is, “I want this handrail to be where it is easiest to actually complete the task.” But you have the scientists saying, “No, that’s going to you know, break the — this certain piece of equipment, or it’s going to — it’s not going to be able to handle the load of the person that’s actually putting their whole body weight on that.” So, where do you find those happy mediums? How do you work with those teams to make sure you’re doing what you need to do?

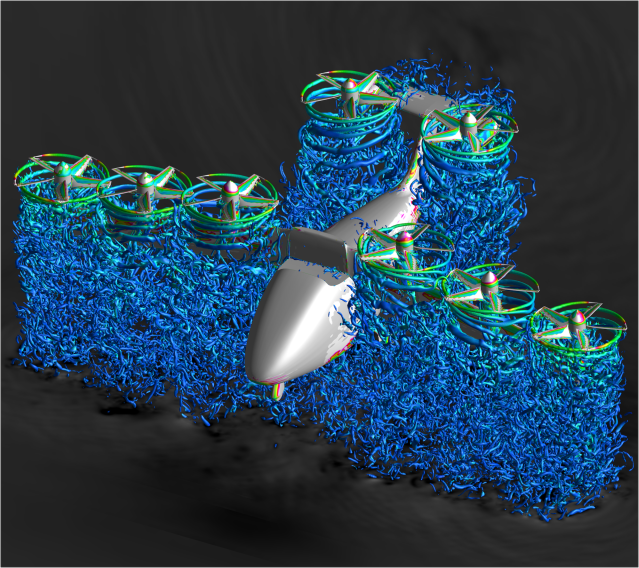

Brian Mader: Lots and lots of discussions. So, one of the stories I love to tell in this regard too, is just what it takes to operate in the spacesuit. You know, we’ve talked about that a little bit. In my job, I’ve been working around astronauts in the suit for many years, and I’ve been in the suit pool myself, which is invaluable to understand, “Oh, that’s why they can’t do that.” But when we bring a team together like this on a piece of hardware that was never intended for spacewalks, the people that built AMS are brilliant. And the — I mean, the things that they put together on that are incredible. But one of the most basic things, we’re installing this new cooling system, the basic thing you need power and you need data. You need to be able to command the pumps and get telemetry. So, early on, one of the — actually the path to get data, was a very, very small connector. About the size of your pinky nail. Not your whole pinky, but just the top part of your pinky finger.

Host: Oh, my God.

Brian Mader: And you know, for people that have put the hardware together on the ground, it makes sense, right? That’s where the data is. That’s where you go get it. But then I look at that and go, “You can’t do that in a spacesuit.”

Host: Yeah.

Brian Mader: So, you know, they had to go off and find and entire new path to get data, and it’s that understanding of you know, “What can the suit do? What can’t the suit do? What kind of space can you get into?” You know, when they built AMS, there were literally people crawling inside of it. Well, you can’t do that in the spacesuit.

Tara Jochim: That’s a really good example, too, of the integration that it took between our communities, right? So, the idea of that connector, didn’t seem like much of a problem to the AMS side of the house, until the EVA community, we had to go over to Europe and explain, “You know what? We’re not able to manipulate that size of a connector, in our big snowmobile gloves,” is what I like to call. You know, the suit gloves, they’re very big and they’re very awkward to handle small detailed items. So, they had to take that information back, somewhat reluctantly in the beginning of, “Hey, this is our best method. Why can’t we design some kind of tool?” And the EVA community needed to help them understand, that you know, “It’s just not going to be safe for your product in the end,” right? “We have a high likelihood of destroying this connector with our gloved hands here.” So, they took that, and they went back, and they came up with another great concept that was much more EVA-able. Now, it’s not perfect and it’s not an EVA connector that we like to use on orbit, but it’s something that we could make work. So again, it’s an iterative process of going back and forth and figuring out, “What’s going to be the best solution for the hardware that we have?”

Host: I love that term, “EVA-able.” But it sounds like it’s definitely like a — it goes both ways, right? So, obviously the AMS folks are telling you, “No, no, no. Don’t put that there.” And then you have to kind of work with that whenever you’re designing your tools, but if you say, “An astronaut is not going to be able to work with that. It’s too fine. We’ve done a bunch of spacewalks before, and it’s just — it’s not going to work. You need to design something new.” I mean they have to run with that. They have to take it and design something new that’s actually going — because ultimately, the whole goal here is everybody’s working together to save this piece of equipment.

Tara Jochim: Absolutely.

Brian Mader: That’s right.

Host: Yeah.

Tara Jochim: Same goal in mind.

Host: Yeah. Alright, so we talked about access. Access is one of the definitely main things for the AMS. You were talking about requirements, Tara. You know, what are the requirements to actually do this? You need to access it. Here are the points that you can actually attach things to, and get to it. And then come the tools. So, how do you pick what tools, how many tools, how to work with tools, how does that even begin? Because these are all brand new, right?

Brian Mader: She tells me no. [Laughter]

Tara Jochim: That’s right. I tell him no.

Host: You tell him no.

Brian Mader: I say, “I want them all.”

Tara Jochim: You know, it was some trial and error in the beginning. Engineers had some great concepts. The operations guys had some other concepts. And it was kind of a meeting of the minds. How do we come together? Sometimes the engineers would 3D print some tools and we would go over to the ARGOS mockup where we had this AMS standing mockup, and they can physically get in there and we would put on some EVA gloves and see if this tool could fit into the worksite, I f the crew member would be able to reach it with their typical arm length to get in there. Lots of factors that they had to look at. And we’d go back and forth. If something worked, great. If something didn’t, hey, back to the drawing board and they would figure out how to modify maybe that current design, or they’d scrap it all together and come up with another one.

Brian Mader: And one thing that we do where we’re kind of blurring the lines between AMS and, I’ll use air quotes, “normal spacewalks,” so, when we’re developing new hardware, we like to get a good evaluation, right? So, when we’re designing hardware for station, we want to make sure that it’s usable for all the crew members. Different sizes. Different abilities. So, we do — usually we’ll do development runs in the neutral buoyancy lab where we’ll get at least three runs with different crew members, and have them try the tasks. So, we did that early on with this project, too. And quickly found out that because of the access issues that we’ve been talking about, a lot of what we’re working on is recess inside AMS. It actually kind of drives arm length requirements. So, we don’t explicitly have you know — you have to have 47.8-inch arms, or whatever. But we did see in some of the early development, where one person would get in and do a task, no problem. And the next person would get in, and simply could not do it. They couldn’t reach. So, as Tara was talking about, that did drive some of the lengths of some of our hardware as well.

Host: Something — oh, go ahead.

Tara Jochim: Well, I was going to say, those kind of filled in the blanks for our assumptions to begin a project with. You know, we assumed we were going to have, and I had this in every presentation I think I made, was that we were going to have a highly trained, highly skilled, set of EVA crew members be able to go off and do these activities. And we couldn’t name who those EVA crew members were, for a number of reasons. We didn’t know when our hardware was going to exactly be ready. When would AMS be ready for us to be able to go to it and do these activities? You know, lots of different factors. All the stuff we’ve talked about before with space station on how busy station is. When is station going to be able to accommodate these activities? So, it all came down to this past, really this past January that we identified the specific crew, that was going to be on orbit at the time of these activities. And that really drove who was going to be trained then for this set of steps. So, we had a great set of crew members, all the way along for the last four years that have really been an integral part of the team. That’s probably the only part that we haven’t mentioned, from a team perspective is that we had lots of different crew members come in and really give us great feedback. A lot of them have had on orbit experience. Others have had a ton of experience in the pool. And they help us out and help drive us to a conclusion on some of the items that we had that were out there.

Host: Yeah, that’s actually a big part of this discussion, I think would be working with astronauts. Getting their feedback. So, you know, we talked about access. We talked about some of the tools you’re defining these requirements. What do you need? What are you going to use to actually get there? Now, you’ve got to go, and you actually have to test this out. You already talked about a development runs. So, you already talked about you have this idea of how it’s going to work. Hey, let’s test it out with some, it sounds like, astronauts. You were testing that with astronauts. So, what were some of the things they were giving you right off the bat? Who were you working with, and what were some of the feedback they were giving you right off the bat?

Brian Mader: So, we worked with, gosh, over the years, we’ve probably had at least half the astronaut office go through some of our testing and development. We got all kinds of feedback. There’s the running joke.

Tara Jochim: Sometimes that’s the problem.

Brian Mader: Yes. The running joke, “Ask three astronauts for an opinion, and you’ll get five answers.” Right?

Host: Yeah.

Brian Mader: Fill in the blank. That’s not just astronauts. That’s engineers, too. [Laughter] So, and it’s an iterative process, too. So, there are sometimes where we would go in and we’d test a particular tool, and we’d decide, “Hey, we need to go this path. We need to modify it this way.” And we’d get back in the next time, and we’d say, “Well, no, actually we had it right before. We need to go back to that.” So, it’s a whole process and it’s why we take a lot of time. You want to learn those things here on the ground. And you don’t want to learn those in space.

Host: Oh, yeah. You want to know when you’re in space. No surprises. That’s kind of the — one of the main things, I guess, with training and defining these requirements is, limit the amount of surprises you’re going to get. Do the best that you can.

Tara Jochim: Yeah.

Brian Mader: And there’s always going to be unknowns.

Host: Sure.

Brian Mader: It happens every time, but you want to be able to react.

Tara Jochim: Yes, especially in this scenario where the hardware’s not here for us to–

Host: That’s huge.

Tara Jochim: You know, connect things up to and make sure it all fits. Yeah, the crew office has done a really great job from our perspective, of supplying us with folks with experience. Chris Cassidy, Jeremy Hansen, Mike Hopkins, those are some of the main guys that really helped us through this. Kate Rubins, Anne McClain, was in there a couple times. And we just had a lot of folks with real experience, both on the ground and in an orbit, come in and give us ideas. And you know, a lot of times, we would ask for the, “Is this do-able?” kind of thing. Are we even that far down the path? Does this make it a do-able scenario? And sometimes it wasn’t. And you’d start over. And you would keep going. And four years sounds like a really long time to develop a project, but boy, it’s blown by quickly. And I was thinking, Brian and his team was giving a presentation, just this past week to some of the program management and hearing all the training that the crew went through, doesn’t seem like it was that much. Not as much as we wanted in the beginning, right? We just didn’t have available time with the crew. But oh my word, when we were going through it, it was something that was every day. It was constant, constant, constant for months. And I look back now and I was like, “Oh, that wasn’t so bad.” [Laughter] Seeing it on paper doesn’t seem so bad, but over the time period, it was a constant go. Go, go, go. Fitting in schedules, training schedules, all that stuff.

Host: It sounds like — like you said, four years doesn’t really sound that surprising when you’re talking about so much back and forth. You had the back and forth with the AMS teams, trying to figure out who this is all going to work. Then you have the back and forth with the crew to see, you know, “Hey, we have this idea of how we think we’re going to fix this,” and they say, “No, I can’t reach it.” So, that’s huge. That’s a huge piece of feedback, because you need that piece of feedback, and it’s a huge requirement. When you talked about the crew that’s identified on orbit, we knew I believe it is Andrew Morgan and Luca Parmitano.

Tara Jochim: Right.

Host: They are the people that’s going to be doing these spacewalks, because they were most importantly, going to be in orbit at the time that you wanted to do this, but also, meet all of the requirements that you’re talking about. They have the training. And they can reach it, right? That’s got to be a big part of it, is being able to reach it, otherwise, you can’t complete the task.

Tara Jochim: Right.

Brian Mader: Very true.

Host: Yeah. So, tell me about working with them. Getting them prepared for it because this is quite a number of EVA’s that they have to do all in a row, just the two of them. And they have to do it with this piece of hardware that’s not meant to be worked on. So, what was it like working with the two of them?

Brian Mader: So, starting with the past, you know, in shuttle days, crews were assigned about two years before a flight. And they were EVA specialists. So, they were crew members on the flight that their main job on that flight was doing whatever spacewalks for that mission. So, they would spend a year to two years training their exact tasks. And you know, talking about Hubble earlier, one of the Hubble repairs, they did about ten runs in the pool, for every spacewalk that they did. So, I mean, they pretty much had everything memorized, right? And they could–

Tara Jochim: So, I mean think of that. I mean that’s like 40 NBL [Neutral Buoyancy Laboratory] runs they did for one mission.

Host: Wow.

Tara Jochim: Now, listen to what we did for here. [Laughter]

Brian Mader: So, as Tara said, you know, we knew in January that it was going to be Luca and Drew, and they were leaving the country for launch, the end of May, I guess it was, or early June. So, that was our window. We had a four-month window. And by the way, in that four months, they’re not here doing AMS training 100 percent of their time. They still have to go to Cologne and Germany. They still have to go to Japan. They still have to go to Russia to do all their other training. So, of that four-ish months, we probably had two, two and a half months, when they were actually here. So, we crammed as much as we could into their schedule. We did, like we talked about. We did NBL runs. We did ARGOS runs. We have glove boxes over in one of the buildings here where that’s a table-top sized container, and you can put EMU [Extravehicular Mobility Unit] spacesuit gloves in there. You suck all the air out of the container, and now you’ve got essentially pressurized gloves. So, we can put small pieces and they can use that to kind of do part task training is what we call it. So, driving a wrench on this little gizmo. I mean, we’ve pulled out everything we could think of to get these guys up to speed. So, I said ten to one for Hubble. So, for AMS, we’re looking at four EVAs in space. Luca and Drew had seven NBL runs, total.

Host: Wow.

Brian Mader: So, that’s not even a two to one ratio.

Host: Yeah. But that was what you had to — like you said, that’s what you had to work with.

Tara Jochim: That’s what we had. Right.

Host: Yeah.

Brian Mader: Yes, but you asked about working with them. I mean Luca and Drew are great. So, this is Drew’s first spaceflight. He is up there right now, just knocking out of the park.

Tara Jochim: Knocking it out of the park.

Brian Mader: He is doing amazing.

Tara Jochim: Absolutely.

Host: Well, yes. He is. He really is. Even through these battery spacewalks, getting a lot of spacewalk. He’s getting through those skills. So, that’s valuable experience right there. Plus you did mention, I mean that’s — you’re just talking about working with these specific crew members. You’ve been working with crew members for a while now to hone these skills, just the general basis of the skills in designing the procedures.

Brian Mader: Sure.

Host: Which is — which is big. Let’s talk about the training. Let’s talk about what we actually did. We’ve been saying Neutral Buoyancy Laboratory, quite a bit. And just for folks who may not know what that is, what is the Neutral Buoyancy Laboratory and what were the AMS spacewalks like inside of it?

Brian Mader: Sure. It’s a giant swimming pool. It’s a little over six million gallons. And we have a mockup of the space station. It’s 100 feet by 200 feet across, and 40 feet deep. So, a lot of water. Even with that size though, we can’t fit the whole space station in there. So, we’ve got kind of the main central part of the space station. And then kind of spread out across the sides of the pool, we’ve got some of the outer areas. So, AMS is part of the — it’s sitting on top of the main truss section, the backbone of space station. In the pool, it’s kind of set in a corner, not because it’s in trouble, but because you know, that’s where it fit in the pool.

Host: Sure.

Brian Mader: So, you know, we use that for all our spacewalk training from the very beginning, the first time somebody gets in the suit, all the way through the specialized training that we’re talking about, which is a whole other level we haven’t even touched on. We have to you know, when this started, we had to figure out how to build a mockup for the NBL. Right? A lot of what we do in spacewalks, as we already talked about, is generic. It’s large. You know, we’re looking at just big things on the outside of space station. For this, we’re talking very tiny things, inside of a mockup. So, it was very new territory for folks at the NBL too, where there’s concerns for what kind of materials you can use in the water, because metals get eaten. It’s a corrosive environment. So, you know, some of that was trial and error, too, where you know, the first couple of runs we had some brackets and some fasteners that completely rusted out.

Host: Oh.

Brian Mader: So–

Host: So, it’s not even with the techniques or the procedures. It’s just with the manufacturers and the mockup.

Brian Mader: It’s the environment.

Host: Wow.

Brian Mader: Yep, yep.

Host: Do you got to work through all those?

Brian Mader: And we talked about accessing AMS in space. Access in the pool is a big deal, too, right? You’ve got crew members in there for six hours at a time. You don’t want to hang them upside down all day.

Host: Yes. [Laughter]

Brian Mader: So, you know, we had to think about how the mockup was oriented in the pool, which way was up. So, we ended up putting it on its side. And that’s one thing we talk about in my group a lot, the mental gymnastics, right? So, we had a mockup over at ARGOS that when we were doing engineering evaluations, it’s standing — you know, it’s sitting there on the ground. When we were using ARGOS, we would lay it down on its back. When we were in the pool, AMS was in a different orientation. So, every time somebody came to it, you know, it’s like, “OK, wait, wait, wait. Which part am I looking at here? Which ways up?”

Host: But you have to orient it based on what’s the most valuable for that particular training. So, you angled the — you angled the AMS in the pool because in the pool, they would — I mean, you’re floating around in the pool, but you still have gravity affecting you. So, you have to–

Brian Mader: Right.

Host: You know, that would stink to be upside down for that whole time. You keep mentioning ARGOS. What’s ARGOS and what were some of the runs done there?

Brian Mader: So, ARGOS is the Active Response Gravity Offload System. And it’s a really neat tool over in the engineering side of the house, where you’re able to suspend somebody in a hand-gliding harness. And it’s a — basically a giant robot, and it mimics microgravity. They can do planetary gravity, too. Spacewalking, we’re interested in microgravity. They can also hang a spacesuit from it. So, early on, we did the shirt-sleeve, is what we would call it. So, somebody just in the hand-gliding harness. And they could climb around on the AMS mockup, try some of the tools. Once we had an idea of what we thought was going to work, we brought in the spacesuit, and put somebody in that, and then figured out if that would work. So, you know, the early side, the shirt-sleeve environment, it’s a quick turnaround. You can hop in, hop out. You know, try something. Go tweak something, come back. Putting the spacesuit in there. There’s more overhead, right? You’ve got a person in a suit, so it’s a pressurized environment. You’ve got to have oxygen. You’ve got to have a lot of — a lot of other ancillary things to make that happen. So.

Host: So, what was the value of doing some stuff in the pool, and some stuff on the ARGOS? And then you also mentioned some tabletop stuff, too.

Brian Mader: Yeah, so at ARGOS, we’ve got a very high-fidelity mockup. So, we’re not concerned about the corrosive pool environment, right? So, we could build it — and it’s also — people are just working on it, shirt-sleeve, right, so, they can build anything they need to. The NBL mockup, they did all the initial construction out of the water, but then once it goes in the water, it’s a pretty big deal to take it in and out of the water. They’ve got to get a crane and a whole team to do that. So, once it’s in there, it pretty much stays in there, and only comes out maybe once or twice a year. So again, at ARGOS we did more high-fidelity training where the mockup was a lot more flight-like, is what we like to say. Whereas the Neutral Buoyancy Lab was — you know, it didn’t have all the detail in the mockup. It had the detail where we’re actually working, but some of the surrounding structure maybe wasn’t even there. So, it’s a little bit–

Tara Jochim: And I would say that ARGOS was invaluable during the development phase of the project. Very early on, it allowed us from a quick turnaround perspective. We could go over there and only spend a few hours with a very small team of people, and allow the engineers to get in the sling. The harness, you know, the hand-gliding harness, to allow them to be over the mockup and really work in the worksite. It helped them, I think, you know, visualize how their tools were going to work, or what they needed to alter in their tools to make them work. It was a — just a great process for us, you know, to be able to iterate those different changes and work quick, quick, things, which was great. And the NBL is fantastic for training, and more of a real environment. But that ARGOS was just invaluable to us in being able to process through everything in the amount of time that we did.

Host: Yeah. Just that you’re kind of — you make the design. You have an original, I guess high-fidelity mockup. This is kind of what we’re going to be working with, but you know, refining those things, that’s invaluable. And plus, being an engineer where you have to say, “Hey, I’ve got to strap myself into that harness, guys. Sorry, it’s for science.”

Tara Jochim: It was pretty rough for them, yes.

Brian Mader: Take one for the team. Yeah.

Tara Jochim: Yes.

Host: OK, so, let’s walk through some of the spacewalks that you have. Brian, you mentioned four, where — we’ve actually — that’s a new number to me, because I think originally we were looking at a little bit more.

Brian Mader: Yeah, so early on, you know, we — when this first started, we really had no idea, right? And then you kind of — you kind of estimate by what you think it’s going to be. So, early on, we were saying between three and five EVAs was kind of the rough guess. After Luca and Drew went through all of their NBL runs, one of the things we do, we keep time-tracking, for all the tasks. So, I’m sitting there with the pen and paper. Everything they’re doing, I’m recording how long it takes them. It gives us an idea of how long it’s going to take in space, right? So, the pool isn’t exact. The hardware isn’t exact. The procedures aren’t exact, but it gives us a good gauge. So, once they went through those seven NBL runs, I was able to sit down and compile all that data, and do the math, and put things together. There’s a lot, a lot, that goes into packaging all the different tasks into EVAs, so generally we try and — we keep it to six and a half hours. A whole other podcast to talk about why. But you know, there’s efficiencies, too, right, because you’ve got to setup the worksite. You’ve got to bring all the tools out. You’ve got to open up the bag. So, you try and group things a certain way, so it fits in that, right? But basically, you take the times from the pool, and again, going back to the generic spacewalks, we don’t always have that information, right, because people might be on orbit before we even know we’re doing that spacewalk. But we have the luxury in this case of knowing Luca and Drew’s times, we were able to extrapolate that to what we think it will be on orbit. So, we’re able to package everything. We are stretching that six and a half hours a little bit on the middle two EVAs. We think those are going to go a little bit longer. But it’s what allows us to get to four EVAs instead of five.

Host: Which is, I guess ultimately, yeah it’s a little bit longer in the middle, but for the crew, taking away another day of spacewalking, Tara, I think we went over this a little bit when we talked about how to plan a spacewalk. I mean, a lot of it just has to do, if I had to shorten it, with just how much time before and after the spacewalk. It’s very taxing for the crew, so it’s just a long day. Anything you can do to help them with another long day, I think would be much appreciated. Plus, as we’ve mentioned before, there’s a lot of other things going on in space station.

Tara Jochim: Absolutely.

Host: So, let’s walk through the spacewalks. If we had to do a summary of each of the four, what are the main tasks that we’re looking at for each of them?

Brian Mader: So, the first one is basically just getting access to everything. It’s opening up the worksite. Taking off a couple of different shield covers, and that’s pretty much it for the first one, which might not sound like much, but again, we’re talking all those non-captive fasteners. It’s very time consuming. The second EVA is when we get into kind of getting ready to bring the new pump system out. So, we access the power cable, the data. We actually cut tubes on that one. So, that’s when we put AMS on life support or however you want to say that. But at that point, their cooling system is no longer working. We cut into it, and it’s on life-support. So, and that’s pretty much the content of that at a high level. The third EVA is when we bring out the new pump system, we install that, and then we’ve got, I think Tara said it earlier, we’ve got eight tubes that we’re connecting. So, the box has all this plumbing on it, outside, and stainless-steel tubing. It’s about the width of a pencil. And it’s a piece of art. It’s really amazing how, and for everybody listening, you should go out and find pictures of this box because the way the engineers figured out how to coil these tubes on the box. It is two things, right? You don’t want this big spider coming out of the airlock. It would never make it out. So, you want to keep things contained, but we need the length on these tubes to really route it inside AMS and connect to the lines that we’re connecting to. So, it’s really a piece of art. But we make all those connections, those eight connections. There’s six in one location, and then two more on the nadir side or the bottom side of AMS. And that’s the bulk of the third EVA, is making all those connections. The fourth EVA is really coming out and, so the fittings that we’re using have a built-in leak check mechanism. If it’s leaking, it has a visual indicator that will show that. So, we come out and we look at those leak indicators. If there is a leak, then we take action. Hopefully, that’s not going to happen. But you know, that’s why it’s there. And then we close everything out on that EVA. So, we took off those shields, those covers, a lot of MLI or Multilayer Insulation. All of that needs to be covered back up for thermal reasons. So, we’ve got several new blankets that we’re installing on AMS.

Host: OK. There it is. That’s the task. It makes logical sense

Tara Jochim: Easy. Really sounds easy when you talk about it, Brian. Piece of cake.

Host: Four years of work? Not a problem. So, Brian, tell me what you’re going to be doing as the — or helping out in Mission Control, real time?

Brian Mader: Sure, so I’ll be in the back room, and we’ve got a lot of folks. So, during any spacewalks, we’ve got — gosh, I can’t even do the math in public on how many people are involved. There’s a lot of people. So, we got the main Mission Control Center that you see on TV. We’ve got the MER, [Mission Evaluation Room] which is a team of engineers in basically, another mission control room.

Host: Mission Evaluation Room, I think.

Brian Mader: That’s right, yeah. And then every — so pretty much every person you see sitting in the Mission Control Center, there’s at least one, in some cases four or five people in a back room, that are supporting that person as well. So, everybody’s talking on the communication loops. We’re all in headsets. My role is kind of that intermediary, where I’ll be talking directly to the engineers, the AMS folks, the tool folks, and anybody else that I need to. Sometimes there’s other people you need to talk to. And then, communicating information back and forth. So, I’m the one that’s written the procedures. So, I’m also following along to what the crews is doing, making sure that they’re getting through things that they need to get to. If there’s any trouble, we have what we call a crib sheet, which — Tara, how many hours do you think we spend developing one of those?

Tara Jochim: Oh, my goodness. Many, many, many, many.

Brian Mader: We spend a lot — so, we spend a lot of time developing the nominal procedures, or the you know, the regular procedures. And then we take those procedures and every step in that procedure, we say, “Oh, what if that doesn’t work? What if that doesn’t work? What if this breaks? What if that–?” So, it’s a lot of “what-if.” But again, it’s — spacewalking time is so valuable, you don’t have the luxury of saying, “OK, guys. Just hang out for the next three hours while we talk about this, right?” You need to have a plan going in. So, you know, I’m following along, and if we do need to go to that crib sheet, you know, I’ll be the one saying, “Hey, we’re on crib sheet, page 47.” Whatever it is.

Tara Jochim: Well, and he talks about that crib sheet. And going back to the normal EVAs and things that we do, we have a toolbox on orbit. We have other tools that can help us through some of these crib sheet items that occur. Sometimes, we have to go create things from new, either from internal tooling that we have there, or sometimes you may have to launch something new. Well, from the AMS perspective, this whole worksite is so unique. We don’t have a toolbox up there. So, we really had to step through and think about things, “What can we protect for?” We’ve got limited time, limited budget. You know, what are the events that we think is most likely to occur, and how would we recover from those incidents? So, just recently, in the past week actually, they determined there was one other thing that we really needed to go protect for, in that crib sheet or that failure scenario. So, we just created a couple new tools that we’re going to launch on the vehicle here in the coming weeks. So, it’s very quick turnaround. Very quick way of thinking about the tool itself, and this is just kind of that throwing the kitchen sink at — you know, at the failure. If this occurs, we’re going to be stopped. So, let’s come up with a solution before it occurs and be able to fix in real time. So, that’s our goal with that.

Host: I think a lot of people can relate to that. Just you work so hard on something, and it’s getting up to like when it’s actually going to start kicking off, and you just you want to, you know, make sure everything is right in place, and tweak this, and just double-check that, triple-check that. It sounds like you’re even making some changes even now. How you feeling coming up to it? Is it – are we– do you feel good that it’s coming up so soon, and we’re going to actually kick this off and all that four years, probably more of hard work going into it, are going to start paying off soon?

Tara Jochim: Oh, absolutely. I’m very excited about it. We joked for a long time that we could you know, see the tunnel, and the light at the end of the tunnel. We didn’t know if it was the train or if it was actually the end of the tunnel. And I really feel like there’s no longer a train. It is the end of the tunnel and we’re really — we’re going to go off and do this. And we’re going to be successful, and it’s going to be a great ride for everyone that’s involved in it, and just really looking forward to the success we’re going to have in the next few months.

Host: That’s awesome. Brian, you feeling good?

Brian Mader: I’m looking forward to it. So, one of the great things, you know, crew members love going outside, outside the space station. They talk about the views and all that. They get really excited about doing spacewalks. This is kind of the epitome of what we do here, right? Where we’ve developed a lot of new things, a lot of off-the-wall thinking, too. So, looking forward to seeing it.

Tara Jochim: Well, it’s neat to see — from this project, we don’t always get this perspective anymore, because we already have that toolbox on board, and all those things have been developed. This, you know, is a new creation, so to speak and we watched it grow from infancy, all the way up here now. And now we’re going to see it out in space, being used. And it’s just awesome to be able to see that entire process. What a great team that has been involved with this all the way along. And it’s just going to be super to see it all come together.

Host: I’m so excited for you both. Tara and Brian, thank you so much for coming on the podcast today, and really, best of luck to you. Best of luck to the teams. Best of luck to the astronauts. Really looking forward to kicking this off. Thanks again.

Tara Jochim: Appreciate it. Thank you.

Brian Mader: Thanks for having us.

[ Music ]

Host: Hey, thanks for sticking around. We had a fascinating discussion with Tara Jochim and Brian Mader about the Alpha M agnetic Spectrometer spacewalks today. Very exciting time. I really hope you tune in to watch them. You can go to NASA.gov/NTV to look at the schedule for when we’re going to be actually conducting these spacewalks. And you’ll find some more information about the spacewalks at NASA.gov. If you want to know more about the space station, NASA.gov/ISS. And if you really love NASA podcasts, we’ve got a lot of them at NASA.gov/podcast. I would highly recommend that you go and watch the NASA documentary called “AMS: The Fight for Flight,” to learn more about the history and struggle of getting the Alpha Magnetic Spectrometer on the space station. It’s available through a link on the episode web page. Otherwise, you can follow us at the NASA pages or the International Space Station pages, or where we are at the NASA Johnson Space Center pages, of Facebook, Twitter, and Instagram. Use the hashtag #AskNASA on your favorite platform to submit an idea for the show, and make sure to mention it’s for Houston, We Have a Podcast. This episode was recorded on October 9th, 2019. Thanks to Alex Perryman, Pat Ryan, Norah Moran, Belinda Pulido, Rachel Barry and the International Space Station Program Science Office team. Thanks again to Tara Jochim and Brian Mader for taking the time to come on the show. We’ll be back next week with the last episode on this series of the Alpha Magnetic Spectrometer.