Chapter 14

The Advanced Turboprop Project:

Radical Innovation

in a Conservative Environment

by Mark D. Bowles and Virginia P. Dawson

In 1987, a Washington Post headline read, "The aircraft engine

of the future has propellers on it."1

To many this statement was something like heralding "the reincarnation

of silent movies."2 Why would an "old

technology" ever be chosen over a modem, new, advanced alternative? How

could propeller technology ever supplant the turbojet revolution? How could

the 'Jet set mind-set" of corporate executives, who demanded the prestige

of speed and "image and status with a Jet," ever be satisfied with a slow,

noisy, propeller-driven aircraft? 3

A Washington Times correspondent predicted that the turbojet would

not be the propulsion system of the future. Instead, the future would witness

more propellers than Jets and if "Star Wars hero Luke Skywalker ever became

chairman of a Fortune 500 company, he would replace the corporate jet with

a ... turboprop."4 It appeared that

a turboprop revolution was underway.

NASA Lewis Research Center's Advanced Turboprop Project (1976-1987)

was the source of this optimism. The energy crisis of the early 1970s served

as the catalyst for renewed government interest in aeronautics and NASA

launched this ambitious project to return to fuel saving, propeller-driven

aircraft. The Arab oil embargo brought difficult times to all of America,

but the airlines industry, in particular, suffered and feared for its future

in the wake of a steep rise in fuel prices. NASA responded to these fears

by creating a program to improve aircraft fuel efficiency. Of the six projects

NASA funded through this program, the Advanced Turboprop Project promised

the greatest payoffs in terms of fuel savings, but it was also the most

conceptually radical and technically demanding.

The project began in the early 1970s with the collaboration of two engineers,

Daniel Mikkelson from NASA Lewis, and Carl Rohrbach of Hamilton Standard,

the nation's last major propeller manufacturer. Mikkelson, then a young

aeronautical research engineer, went back to the old NACA wind tunnel reports

where he found a "glimmer of hope" that propellers could be redesigned

to make propeller-powered aircraft fly faster and higher than those of

the mid to late-1950s.5 Mikkelson and

Rohrbach came up with the concept of sweeping the propeller blades to reduce

noise and increase efficiency and NASA received a joint patent with Hamilton

Standard for the development of this technology. At Lewis, Mikkelson sparked

the interest of a small cadre of engineers and managers. They solved key

technical problems essential for the creation of the turboprop, while at

the same time they attracted support for the project. After a project office

was established, they became political advocates, using technical gains

and increasing acceptance to fight for continued funding. This involved

winning government, industry, and public support

1. Martha M. Hamilton, "Firms Give Propellers a New Spin," Washington

Post, February 8, 1987.

2. Robert J. Serling, "Back to the Future with Propfans," USAIR

(June 1987).

3. R.S. Stahr, Oral report on the RECAT study contract at NASA, April

22, 1976, Nored papers, NASA, Lewis Research Center, box 224.

4. Hugh Vickery, "Turboprops are Back!," Washington Times, November

1, 1984, p. 5B.

5. Interview with Daniel Mikkelson, by Virginia Dawson and Mark Bowles,

September 6, 1995.

321

322 THE ADVANCED TURBOPROP PROJECT

|

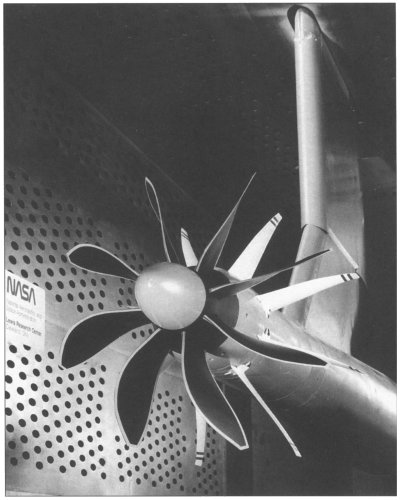

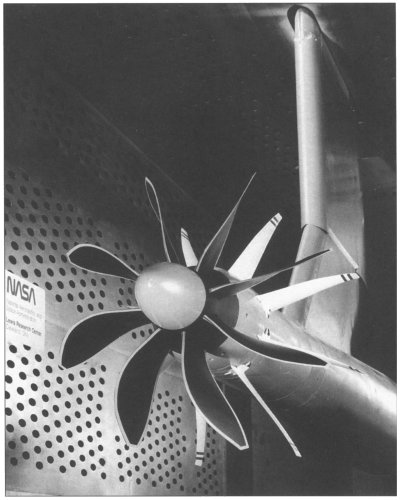

| An advanced propeller swirl recovery model is shown

in the NASA Lewis Research Centers 8 x 6 foot supersonic wind tunnel. Propeller

efficiencies and noise are measured at cruise much numbers up to 0. 80

and at takeoff and approach conditions. Vane pitch angles and propfan-to-vane

axial spacings are varied. The testing was part of the Advanced Turboprop

Project, with the goal of providing the technology base to enable the U.S.

development of quieter, fuel efficient turboprop engines with a comfortable

aircraft interior environment. (NASA photo no. 90-H-78). |

FROM ENGINEERING SCIENCE TO BIG SCIENCE 323

for the new propeller technology. Initially the project involved only

Hamilton Standard, but the aircraft engine manufacturers, Pratt & Whitney,

Allison, and General Electric, and the giants of the airframe industry,

Boeing, Lockheed, and McDonnell Douglas joined the bandwagon as the turboprop

appeared to become more and more technically and socialIy feasible. The

turboprop project became a large, well-funded, "heterogeneous collection

of human and material resources" that contemporary historians refer to

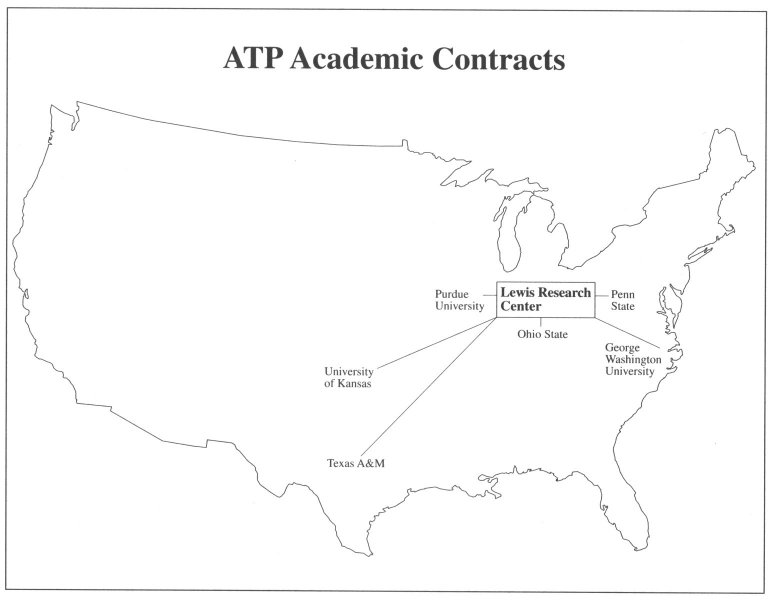

as "big science."6 At its height it

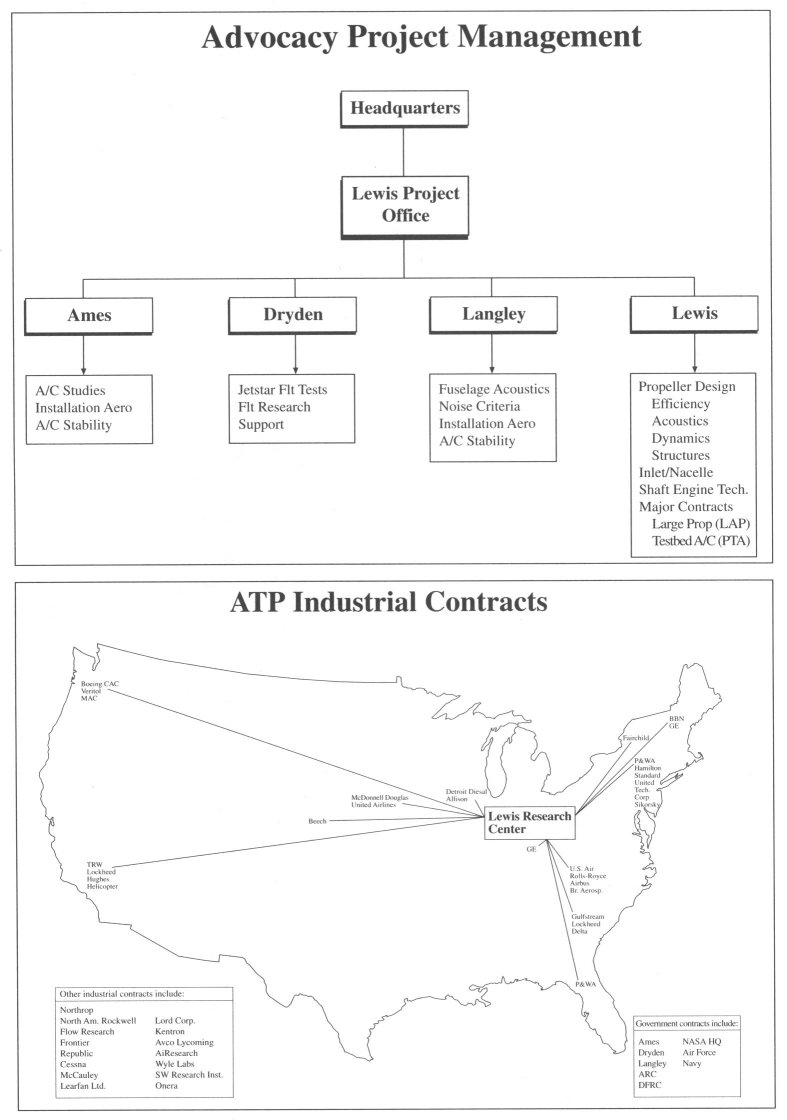

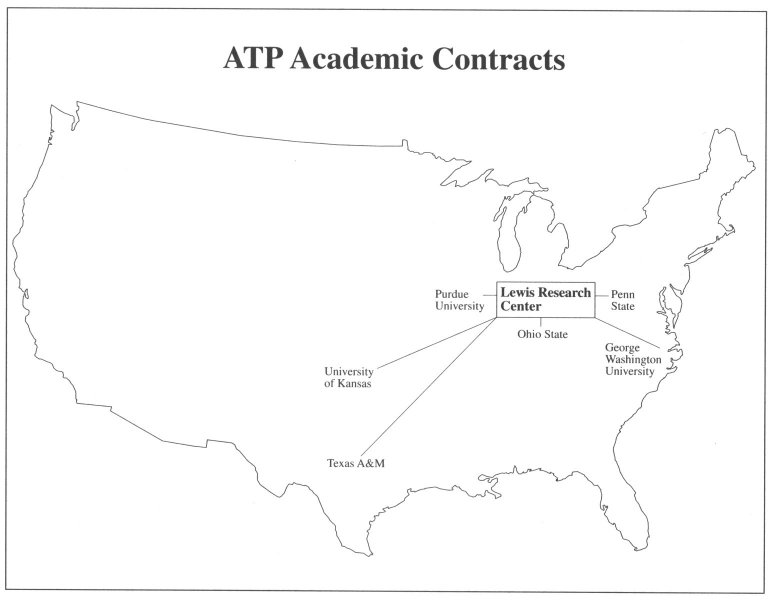

involved over forty industrial contracts, fifteen university grants, and

work at the four NASA research centers, Lewis, Langley, Dryden, and Ames.

The progress of the advanced turboprop development seemed to foreshadow

its future dominance of commercial flight.

The project had four technical stages: "concept development" from 1976

to 1978; "enabling technology" from 1978 to 1980; "large-scale integration"

from 1981 to 1987; and finally "flight research" in 1987.7

During each of these stages, NASA's engineers confronted and solved specific

technical problems that were necessary for the advanced turboprop project

to meet the defined government objectives concerning safety, efficiency

at high speeds, and environmental protection. NASA Lewis marshaled the

resources and support of the United States aeronautical community to bring

the development of the new technology to the point of successful flight

testing. In 1987, these NASA engineers, along with a wide-ranging industry

team, won the coveted Collier Trophy for developing a new fuel efficient

turboprop propulsion system.8 The winning

team included Hamilton Standard, General Electric, Lockheed, the Allison

Gas Turbine Division of General Motors, Pratt & Whitney, Rohr Industries,

Gulfstream, McDonnell Douglas, and Boeing certainly the largest, most

diverse group, to be so honored in the history of the prize.

Despite this technical success, the predicted turboprop revolution never

came, and no commercial or military air fleet replaced their jets with

propellers. The reason for this failure was socio-economic, not technical.

Throughout the project, social issues influenced and defined the status

of the advanced turboprop. From the beginning it was the perception of

an energy crisis, not a technological innovation, that spurred the idea

of the project itself. The Cold War and the existence of Soviet high-speed

turboprops played a key role in convincing Congress to fund the project.

As the project progressed, within each technological stage, the engineers

used distinctive and creative approaches to deal with the complex web of

government, industry, and academic contractors. More often than not, the

main question was not does the technology work, but how can we get government,

industry, and the public to accept this technology? In the end it was a

socioeconomic issue again which shelved the program. The reduction of fuel

prices ended the necessity for fuel conservation in the skies and today

the advanced turboprop remains a neglected, or "archived" technology.

This is not to imply that the technical achievements were unimportant.

Each distinct technical stage of the project determined a corresponding

social action. During the concept development stage, creative advocacy

was necessary to sell the government and industry on this radical idea.

During the enabling technology stage, engineers used complex project management

skills to ensure that this massive team would function effectively. During

the large-scale integration stage, NASA had to deal with a competitor that

surprised them by introducing its own high-speed turboprop. Finally, during

the flight research stage, NASA became aware that no current airlines would

adopt the advanced turboprop and thus the

6. See James H. Capshew and Karen A. Rader, "Big Science: Price to

the Present," Osiris, 2nd ser., 7 (1992): 3-25.

7. Roy D. Hager and Deborah Vrabel, Advanced Turboprop Project

(Washington, DC: NASA SP-495, 1988), p. 610.

8. Citation for the Collier Trophy in Roy D. Hager and Deborah Vrabel,

p. vi.

324 THE ADVANCED TURBOPROP PROJECT

engineers waged a battle to win the Collier Trophy to try and gain positive

status and recognition for their technical achievement.

The relationship between these technical and social spheres was never

either a simplistic story of social construction or technological determinism.

Rather, the relationship was one of interdependence. At times the project

advanced on its technical merits; at others, it progressed through political

persuasion. At each stage, only after NASA engineers and their industrial

and academic partners solved both the social and technical problems holding

it back, was the advanced turboprop project able to obtain funding and

move forward. But ultimately, the socio-economic issue of petroleum price

and availability managed to scuttle NASA's technical success.

Thomas Hughes, a prominent historian of technology, has argued that

the research and development organizations of the twentieth century, no

matter whether they are run by a government, industry, or members of a

university community, stifle technical creativity.9

In these organizations there can be found "no trace of a flash of genius."10

In contrast, the late 19th century for Hughes was the "golden era" of invention

a time when the independent inventor flourished without institutional

constraints. Recently, David Hounshell has challenged Hughes's contention

that industrial research laboratories "exploit creative, inventive geniuses;

they neither produce nor nurture them."11

Not only can the industrial research laboratory nurture a creative individual,

but collectively, people engaged in research and development contribute

to making an invention a commercial reality. In his study of the organization

of research at Du Pont, Hounshell paid tribute to the individual brilliance

of the organic chemist Wallace H. Carothers, but he argued that the real

"genius of nylon was in the organization that developed it into one of

the most successful and profitable materials of the twentieth century."12

In our view, the NASA Advanced Turboprop Project represents another case

in which organizational capabilities, not individual genius alone, create

the opportunity for significant innovation. The organization that supported

the development of the turboprop was far more complex than the research

laboratory of an industrial firm, yet it responded to the energy crisis

to advance a radical idea. As Donald Nored, who headed the office at NASA

Levis Research Center that managed the three aircraft energy efficiency

projects remarked, "The climate made people do things that normally they'd

be too conservative to do."13 The

history of the advanced turboprop demonstrates how a radical innovation

can emerge from a dense, conservative web of bureaucracy to nearly revolutionize

the world's aircraft propulsion systems.

The Conservative Team Environment

Although NASA won several Collier trophies for innovations related to

the space program, it had produced no winners in aeronautics since the

founding of the agency in 1958. NASA's predecessor organization, the National

Advisory Committee for Aeronautics (NACA), had received five Collier trophies

for contributions to aeronautics between 1929 and 1958. These trophies

paid tribute to the individual creativity and the unique research environment

of the NACA's research laboratories. James R. Hansen has described in this

volume how engineer Fred E. Weick used the NACA's unique wind tunnel facilities

to develop

9. Thomas P. Hughes, American Genesis: p. 54.

10. Ibid., p. 183.

11. David A. Hounshell, "Hughesian History of Technology and Chandlerian

Business History: Parallels, Departures, and Critics," History and Technology

12 (1995): 217.

12. Ibid. See also, David A. Hounshell and John Kenly Smith, Jr., Science

and Corporate Strategy: Do Pont R&D, 1902-1980 (Cambridge, MA:

Cambridge University Press, 1988).

13. Interview with Donald Noted at Case Western Reserve University

by Virginia Dawson and Mark Bowles, August 15, 1995.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 325

the NACA low-drag cowling. Succeeding Collier trophies awarded under

the institutional aegis of the NACA followed a similar pattern. Lewis A.

Rodert won it for developing a thermal ice prevention system for aircraft

(see the essay by Glenn E. Bugos, this volume), John Stack won it twice

for his contributions to supersonic theory and the development of the transonic

wind tunnel, and Richard Whitcomb carried off the prize for his discovery

and empirical validation of the area rule. What made the award garnered

by the NASA/industry team in 1987 different was that it recognized the

collective talents of government engineers from four NASA research centers,

academic researchers, and contractors from the propeller, engine, airframe,

and airline industries.

The history of the turboprop project is interesting from an institutional

standpoint because it took root and flourished within NASA's conservative,

bureaucratic environment. It was modeled, not on NASA's small-scale aeronautical

research projects (typically carried on by former NACA laboratories), but

on the large-scale projects of the space program. The NASA Lewis Research

Center adopted an administratively complex team approach that depended

on input not simply from other NASA Centers, but also from numerous industrial

and university contractors. Essentially, NASA Lewis Research Center became

the center of an extensive government-industry-academic complex. At each

stage in the project, the management team determined what needed to be

done and sought the appropriate help both from within and outside NASA.

With its expertise in propulsion technology, the NASA Lewis Research

Center was ideally suited to manage the turboprop project. Set up in Cleveland,

Ohio, during World War II as an aircraft engine research laboratory, Lewis

became the third laboratory of the National Advisory Committee for Aeronautics.

Lewis engineers pursued aircraft engine research in the national interestoften

over the objection of the engine companies who perceived the government

as interfering with the normal forces of supply and demand. During the

early years of the Cold War, the laboratory participated in engine research

and testing to assist the engine companies in developing the turbojet engine.

After the launch of Sputnik, the laboratory focused on a new national priority-rocket

propulsion research and development. Almost all work on air-breathing engines

ceased for nearly ten years.

The return to aircraft engine research coincided with drastic reductions

in staff, mandated by cuts in NASA's large-scale space programs.14

The mass exodus of nearly 800 personnel in 1972 sparked an effort to redefine

the center's mission and find new sources of funding. The following year,

OPEC's oil embargo galvanized the Center's director, Bruce Lundin, to look

for ways to use its propulsion expertise to help solve the energy crisis.

In 1974, Lewis received $1.5 million for a wind-energy program from the

National Science Foundation and the Energy Research and Development Administration

(ERDA). A program in solar cell technology development followed on its

heels with increasing funding of various energy-related programs by ERDA

and its successor, the Department of Energy. The changing focus of the

Center's activities prompted rumors-emphatically denied-that it would become

part of ERDA. The new emphasis on energy efficient aircraft, unlike the

ERDA projects, promised to keep Lewis strongly in NASA's fold.15

Moreover, it brought high visibility to the aeronautics side of NASA, long

overshadowed by the enormous budgets and prestige of the space program.

Although it shared similarities in management with NASA's space projects,

the turboprop project differed in significant ways. First, although the

advanced turboprop was the reincarnation of an old idea, it involved the

creation of cutting-edge technology. Space

14. Virginia P. Dawson, Engines and Innovation: Lewis Laboratory

and American Propulsion Technology (Washington, DC: NASA SP-4306, 1991).

15. Ibid.

326 THE ADVANCED TURBOPROP PROJECT

projects involved rigorous oversight, but generally relied on existing

technology. When necessary, NASA contracted with industry to produce whatever

new technology was needed for a particular mission. The turboprop project

tapped the creative talents of engineers at NASA in ways that were reminiscent

of the NACA tradition of in-house research, though in management scope

it transcended the narrow institutional boundaries of NASA's research centers.

Second, though all NASA projects of the early 1970s needed to be "sold"

to an increasingly tight-fisted Congress, the controversial nature of the

turboprop meant that NASA Lewis had to build support both at Headquarters

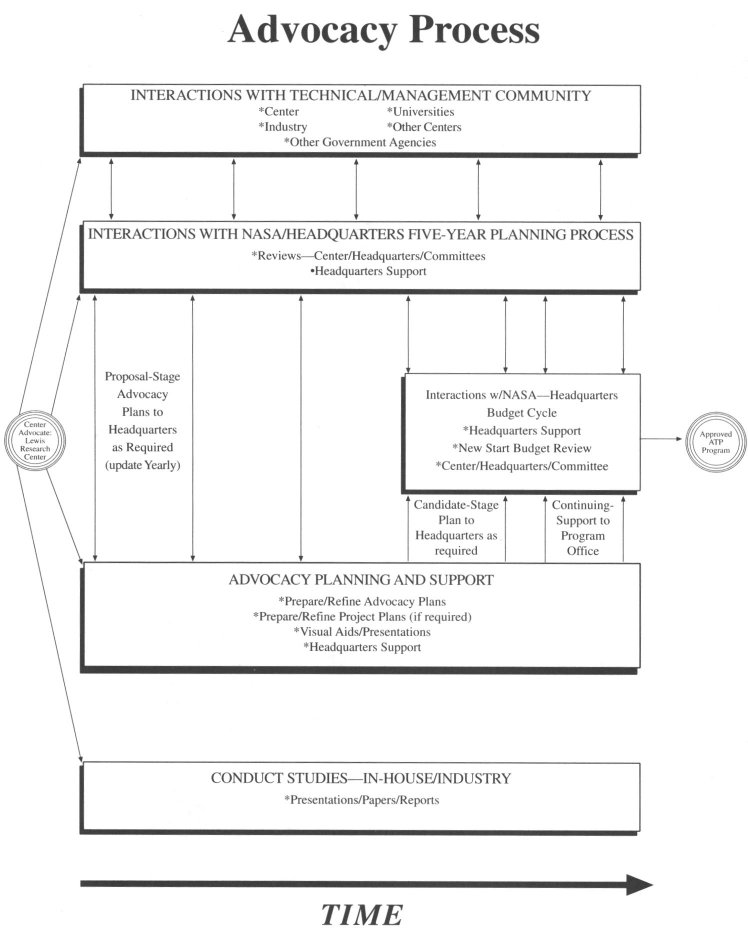

and within the aviation community. What NASA referred to as "advocacy"

needed to be vigorous and continuous throughout the life of the project.

The Energy Crisis and the Politics of Funding

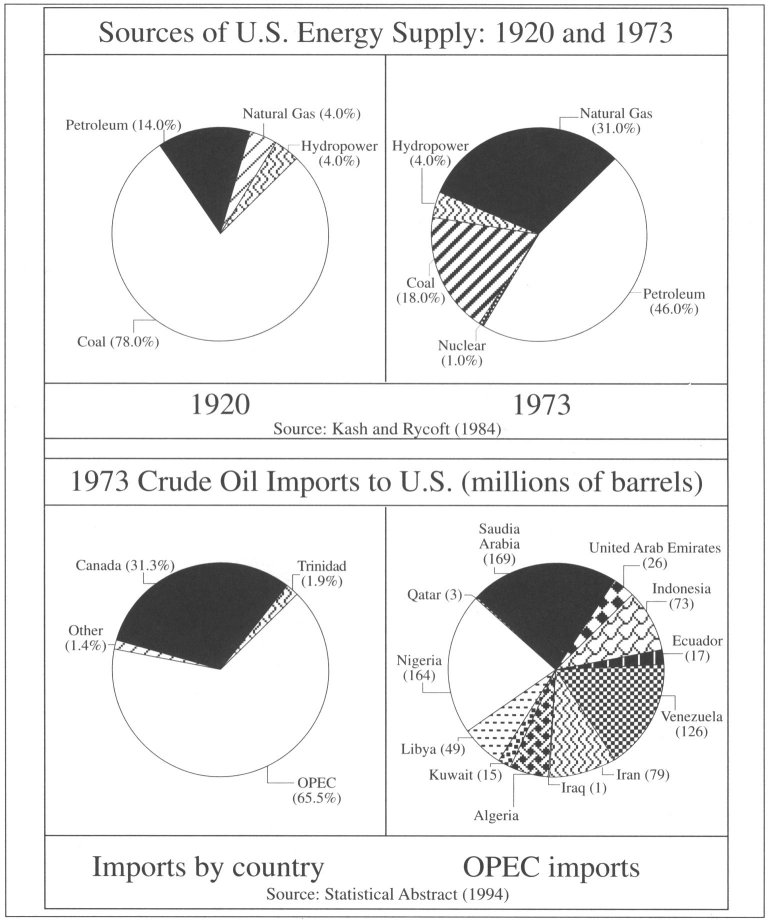

The OPEC oil embargo of 1973 awakened the United States to the degree

of control outside nations had over the lives of every American. The increased

price of oil affected all areas of the economy, but none more than the

airlines industry.16 Earl Cook, noted

geographer and geologist, has argued, "Whoever controls the energy systems

can dominate the society."

17 An extension

of this argument is, whoever possesses the fuel supply controls the energy

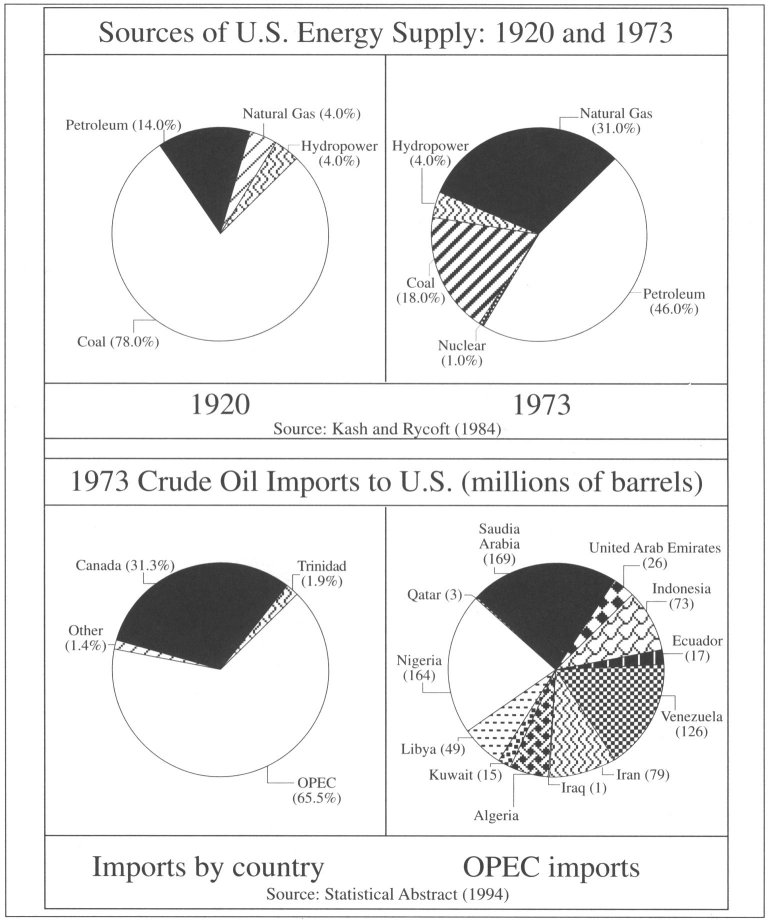

systems. Five sources of energy, including petroleum, natural gas, coal,

hydropower, and nuclear, accounted for all fuel consumption in the United

States during 1973. Of these five sources, America was most dependent upon

petroleum, consuming approximately seventeen million barrels of oil a day.18

At no other time in American history was Cook's aphorism more evident than

in 1973 when the United States imported six million barrels of oil a day,

64 percent of which came from the Organization of Petroleum Exporting Countries

(OPEC).19 The concern in the United

States was that since OPEC controlled the petroleum, could they dominate

American society?

In response to the energy crisis, in 1973 the airlines industry initiated

its own fuel-saving program which reduced fuel consumption by over one

billion gallons per year.20 But these

measures were not enough. jet fuel prices jumped from twelve cents to over

one dollar per gallon and total yearly fuel expenditures increased by one

billion dollars, or triple the earnings of the airlines. Prior to 1972,

fuel accounted for one-quarter of the commercial airlines' total direct

operating costs.21 During the crisis,

fuel represented over half of the airlines' operating costs. The result

was a reduction in the number of flights, the grounding of some aircraft,

and the "furloughing" of some 10,000 employees. If the situation in the

early 1970s seemed bad, prospects for the future appeared even worse. Linking

the fate of the airlines, the cost of jet fuel and the prosperity of the

nation as a whole, airlines industry lobbyists rushed to their congressmen.

The politicians, in turn, appealed to NASA.

16. The Israeli victory during the Six-Day War in 1967 resulted in

retaliation by OPEC. Seeking to force a pro-Arab stance from the United

States (Israel's ally), Saudi Arabia imposed an American oil embargo concurrent

with the quadrupling of oil prices from the other OPEC nations. See Don

Peretz,

The Middle East Today 5th ed. (New York, NY. Praeger, 1988),

154. Gary B. Nash, et al. The American People: Creating a Nation and

a Society 2d ed. (New York, NY: Harper & Row, Publishers, 1990),

p. 971.

17. Earl Cook, Man, Energy, Society (San Francisco, CA: W. H.

Freeman, 1976), p. 208.

18. A barrel contains 42 gallons.

19. In 1973, total U.S. crude oil imports totaled 1,184 million barrels,

765 of which came from OPEC. The OPEC nations at that time included Algeria,

Ecuador, Indonesia, Iran, Iraq, Kuwait, Libya, Nigeria, Qatar, Saudi Arabia,

United Arab Emirates, and Venezuela. Statistical Abstract of the United

States (Washington, DC: U.S. Department of Commerce, 1994), p. 593.

20. Clifton F. Von Kann, testimony before the U.S. Senate, Committee

on Aeronautical and Space Sciences, September 10, 1975, p. 4.

21. Donald L. Noted, John B. Whitlow, Jr., William C. Strack, "Status

Update of the NASA Advanced Turboprop Project," unpublished report, Nored

private papers.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 327

Why was jet fuel so important to our national interest? Clifton F. Von

Kann, senior vicepresident of the Air Transport Association of America,

pointed out in a 1975 Senate statement that airlines were "more than just

another means of transportation ."22

He asserted they played a major part in the economic and military success

of the nation. They also

22. Kann testimony, p. 3.

328 THE ADVANCED TURBOPROP PROJECT

provided the infrastructure for the mail system, the national export

system, and the $60 billion tourist industry. jet fuel was the "life-blood"

of the airlines, but it was also their Achilles heel. He warned a failure

to control the rising cost of fuel might result in either the nationalization

or the withering away of the "basic building block in the structure of

the U.S. economy."23 Senator Barry

Goldwater linked this crisis to the possible "loss of a large part of our

world supremacy."24 The fuel crisis

created an opportunity for NASA at a time when Congress had drastically

cut funding for the space program. Aeronautics, the first "A" in NASA,

had long taken a back seat to the spectacular space missions of the Apollo

years. Now the agency was ready to reassert its role as the nation's premier

institution for research and development in civil aeronautics.

In January 1975, James Fletcher, the NASA Administrator, received a

letter from Senators Barry Goldwater and Frank Moss. 25

The letter suggested a massive technology project involving NASA and industry

to help ease the burden on the airlines caused by the energy crisis. Its

goal was the realization of a new generation of fuel-efficient aircraft.

Goldwater and Moss asked NASA to propose a plan, develop the technology,

and facilitate the "technology transfer process" to industry.26

Technology transfer later became a particularly thorny issue in the debate

over whether the government should carry development to the point of costly

flight testing, or leave that phase to the manufacturers who stood to benefit

handsomely from this government-generated technology.

In February 1975, NASA formed the Intercenter Aircraft Fuel Conservation

Technology Task Force to explore all potential options .27

Sixteen government scientists and engineers from NASA, the Department of

Transportation, the Federal Aviation Administration, and the Department

of Defense took part in the seven-month study. 28

James Kramer, the task force leader, called for any new ideas that would

satisfy government criteria, even those that might be considered "unusual."

The task force defined six major areas with the potential for significant

impact on aircraft fuel efficiency. It recommended the creation within

NASA of the Aircraft Energy Efficiency (ACEE) Program, the administrative

umbrella for six new aeronautics projects three related to the airframe

and three to the propulsion system.29

NASA assigned management of the three propulsion projects to the NASA

Lewis Research Center. The first of these propulsion projects focused on

improving existing turbofan engines through the redesign of selected engine

components. It was the least technically challenging of the three projects

and aimed for a five percent increase in fuel efficiency within a few years.

The second project, the Energy Efficient Engine (E3), involved

building 11 a brand new engine from scratch" and offered a far greater

payoff an increase in fuel efficiency of ten to fifteen percent. In essence,

NASA proposed to assume the risk for developing an "all new technology

in an all up engine."30 With a new

"recoupment program" in place, the government expected to get back some

of its investment out of the profits of the engine manufacturers, General

Electric and Pratt & Whitney.

23. Ibid., p. 5.

24. Senator Goldwater's response to Kahn, ibid., p. 8.

25. It was likely that the NASA staff drafted the letter.

26. Barry Goldwater and Frank Moss to James C. Fletcher, as found in,

Aircraft Fuel Conservation Technology, task force report, September 10,

1975, pp. 138-39.

27. Roy D. Hager and Deborah Vrabel, Advanced Turboprop Project

(Washington, DC: NASA, 1988), p. 4.

28. Aircraft Fuel Conservation Technology, task force report, September

10, 1975, pp. 1 and 2,

29. The Aircraft Energy Efficiency (ACEE) Program airframe projects

included: the Fuel Conservative Transport to improve on aerodynamic design

and potentially save fifteen to twenty percent in fuel use; the Composite

Primary Structures which would decrease the weight of aircraft through

the use of composite materials and save 10 to 15 percent in fuel costs

compared to an all metal airplane; and Laminar Flow Control to allow an

aircraft to maintain low drag, thus creating a potential fuel savings of

twenty to forty percent.

30. Nored interview.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 329

In contrast to these two relatively conservative projects, the advanced

turboprop offered dramatic increases in fuel efficiency. NASA planners

believed that an advanced turboprop could reduce fuel consumption by twenty

to thirty percent over existing turbofan engines with comparable performance

and passenger comfort at speeds up to Mach 0.8 and altitudes up to 30,000

feet. (It should be noted that commuter turboprop-powered aircraft in current

use fly at far slower speeds and lower altitudes.) The ambitious goals

of the turboprop project made it controversial and challenging both from

a technical and social point of view. Technically, studies by Boeing, McDonnell

Douglas, and Lockheed pointed to four areas of concern: propeller efficiency

at cruise speeds, both internal and external noise problems, installation

aerodynamics, and maintenance costs.31

Socially, the turboprop also presented daunting problems. Because of the

"perception of turboprops as an old-fashioned, troublesome device with

no passenger appeal," the task force report noted, "the airlines and the

manufacturers have little motivation to work on this engine type."32

Clifton Von Kann succinctly summed up these concerns to Barry Goldwater

during his Senate testimony when he said that of all the proposed projects,

"the propeller is the real controversial one."33

What made the government willing to assume the risk for such a difficult

project? Proposed fuel savings was one important factor. However, the task

force report indicated another significant and related issue the Soviet

Union had a high speed "turboprop which could fly from Moscow to Havana."34

The continuing Cold War prompted the United States to view any Soviet technical

breakthrough as a potential threat to American security. During the energy

crisis, the knowledge that Soviet turboprop transports had already achieved

high propeller fuel efficiency at speeds approaching those of jet-powered

planes seemed grave indeed and gave impetus to the NASA program. During

the government hearings, NASA representatives displayed several photos

of Russian turboprop planes to win congressional backing for the project.35

The Cold War helped to define the turboprop debate. No extensive speculation

on the implications of Russian air superiority for American national security

seemed necessary. The Soviet Union could not be allowed to maintain technical

superiority in an area as vital as aircraft fuel efficiency. Thus, the

report included the demanding Advanced Turboprop Project as part of the

ten-year, $670 million Aircraft Energy Efficiency Program to improve fuel

efficiency.

Concept Development and Early Advocacy

Industry resistance and NASA Headquarters' sensitivity to the public

relations aspect of this opposition were among the key reasons that of

the six projects within the Aircraft Energy Efficiency (ACEE) program,

only the advanced turboprop failed to receive funding in 1976. John Klineberg,

later director of Lewis Research Center, recalled that it was delayed "because

it was considered too high risk and too revolutionary to be accepted by

the airlines."36

31. Hager and Vrabel, Advanced Turboprop Project, p. 5.

32. Aircraft Fuel Conservation Technology, task force report, September

10, 1975, p. 44.

33. Clifton F. Von Kann, testimony before the U.S. Senate, Committee

on Aeronautical and Space Sciences, September 10, 1975, p. 9.

34. Mikkelson interview.

35. Aircraft Fuel Conservation Technology, task force report, September

10, 1975, p. 48. These Soviet long-range turboprops included the Tupolev

TU-95 "Bear" (which weighed 340,000 pounds, had a maximum range of 7,800

miles, a propeller diameter of 18.4 feet, and operated at a .75 mach cruise

speed) and the Antonov AN-22 "Cock" (which weighed 550,000 pounds, had

a maximum range of 6,800 miles, a propeller diameter of 20.3 feet, and

operated at a .69 mach cruise speed).

36. John Klineberg, quoted in "How the ATP Project Originated," Lewis

News, July 22, 1988.

330 THE ADVANCED TURBOPROP PROJECT

If the advanced turboprop was so important to the national welfare,

why did it encounter such opposition from the airframe and aircraft engine

manufacturers? Donald Nored, the division chief in charge of the three

propulsion projects at Lewis, remarked that his engineering peers in industry

were "very conservative and they had to be." They were "against propellers"

because they had "completely switched over to jets." Because of their commitment

to the turbojet, they continually cited problems that they believed resulted

from propellers. This included noise, maintenance, and the fear that the

"blades would come apart." Nored recalled each problem had to be "taken

up one at a time and dealt with."37

It appears the government's revolutionary vision of the future frightened

the aircraft industry with its large investment in turbofan technology.

Aircraft structures and engines are improved in slow, conservative, incremental

steps. To change the propulsion system of the nation's entire commercial

fleet represented an investment of mind-boggling proportions. Even if the

government put several hundred million dollars into developing an advanced

turboprop, the airframe and aircraft engine industries would still need

to invest several billion dollars to commercialize it. Revolutionary change

did not come easily to an established industry so vital to the nation's

economy.

Turboprop advocates encountered not only the opposition of industry

representatives, but the hesitation and timidity of NASA Headquarters.

By default, the advocacy role fell to NASA Lewis engineers, though the

public relations aspect of technology funding had never been the Cleveland

laboratory's strong suit. Lewis had a reputation for being more conservative

and technical than the other NASA Centers.38

One Lewis engineer remarked that when other Centers sent five representatives

to important meetings, Lewis sent one. Moreover, research engineers from

the aeronautics side of NASA had little experience managing major contracts.

Yet the energy crisis and the need for projects to sustain the Center's

viability within NASA galvanized a small cadre of Lewis engineers into

action. They used their technical and new-found managerial creativity to

sell NASA Headquarters and industry on a revolutionary new propulsion system

one that might forever ground all existing subsonic turbojets.

Technically, the entire future of the advanced turboprop project initially

depended on proving whether a model propfan could achieve the predicted

fuel efficiency rates.39 If this model

yielded successful results, then project advocates would be able to lobby

for increased funding for a large research and development program. Thus,

even during its earliest phase, the technical and social aspects of the

project worked in tandem.

Lewis project managers awarded a small group of researchers at Lewis

and Hamilton Standard a contract for the development of a two-foot diameter

model propfan, called the SR-1 or single-rotating propfan. Single-rotating

meant that the propfan had only one row of blades, as opposed to a counter-rotating

design with two rows of blades, each moving in opposite directions. This

model achieved high efficiency rates and provided technical data that the

small group of engineers could use as ammunition in the fight to continue

the program.

At the same time that they proved the technology using small-scale models,

Lewis engineers built a consensus for the project, defending it against

objections of skeptical segments of industry and government advisory committees.

Advocacy is essentially "marketing" or "selling" to gain government funding

and industry backing for new programs like the advanced turboprop. Funding

government programs is neither scientific nor entirely rational, but depends

on people and how they navigate a complex bureaucracy,

37. Nored interview.

38. Ibid.

39. Aircraft Fuel Conservation Technology, task force report, September

10, 1975, p. 46.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 331

while avoiding numerous political entanglements. During the Apollo years,

NASA had what amounted to a blank check to land a human being on the Moon

within a decade. Not needing to spend time and energy fighting for funding,

engineers had greater freedom to focus on building and testing hardware

and managing space missions. But to keep the programs of the 1970s alive,

even those that responded to a national crisis, required effort in non-technological

spheres of activity.

Lewis was fortunate that Donald Nored, a maestro of project management,

played a strong role in building a constituency in support of the project.

Unlike most of the other Lewis engineers involved in advanced turboprop

development, he hailed from the space side of NASA's house. He had worked

on chemical rockets and high power lasers prior to taking up his post as

head of the Aircraft Energy Efficiency Program Office at Lewis in 1975.

He helped to show aeronautical engineers, more at ease with in-house research,

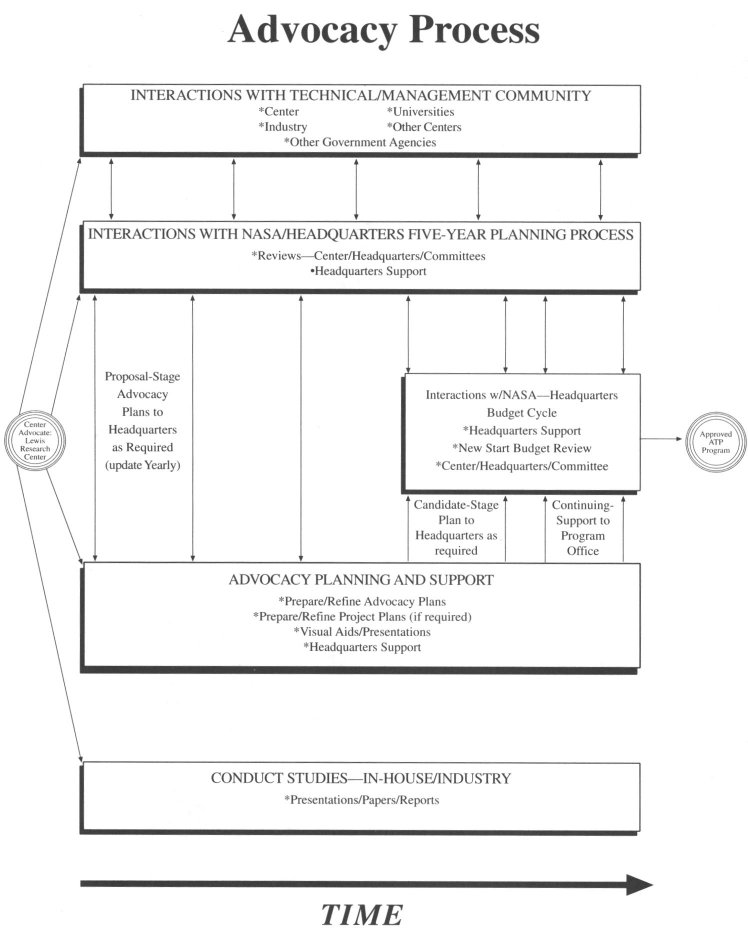

how to negotiate the system to win funding. In 1981, with Frank Berkopec,

Nored attempted to demystify the advocacy process by laying down guidelines

for others within the Aeronautics Directorate. They disabused their order-seeking

engineering colleagues of the notion that advocacy could be compressed

into a series of well-defined steps. Rather, they wrote, it is

332 THE ADVANCED TURBOPROP PROJECT

FROM ENGINEERING SCIENCE TO BIG SCIENCE 333

"basically informal, unstructured, and quite often confusing."40

Since only a few of the proposed NASA programs received funding each year,

they argued, the advocacy process had become essential and activities related

to it should receive a "high priority."41

The advocacy guidelines indicated that the interactions with "industry,

advisory groups, and especially Headquarters will often require rapid,

comprehensive, and in-depth respondents [sic] to requests."42

One early request of the turboprop project centered on the aircraft industry's

concern over the safety of propellers. An aircraft accident advisor raised

a question during a meeting of the Industrial Advisory Board at NASA Headquarters

concerning the "safety aspect of propellers breaking away from the engine

and the damage caused by their impingement into the fuselage."43

Lewis engineers quickly launched their own study into propeller safety

and commissioned similar studies at Hamilton Standard and Detroit Diesel

Allison. The results were overwhelmingly positive. Lewis examined over

12,000 accident reports from 1973 to 1975 and found no instance where a

propeller blade broke away from its engine.44

Hamilton Standard reported that after fifty million hours of propeller

flight time there had never been an instance of structural failure.45

While after twenty million hours, Detroit Diesel Allison found one structural

failure; they were quick to point out that "the aircraft landed routinely

without further incident and no one was injured in the aircraft or on the

ground."46 This example typifies not

only the early skepticism and resistance by industry to the idea of returning

to propeller aircraft but also the "rapid, comprehensive, and in-depth

responses" of NASA to industry's concerns. The advocacy process required

to "market" and "sell" the radical turboprop project was in full swing.

It continued to effectively diffuse the concerns of skeptics.

Enabling Technology and Project Management

Successful advocacy brought the formal establishment of the Advanced

Turboprop Project in 1978 and initiation of the enabling technology phase.

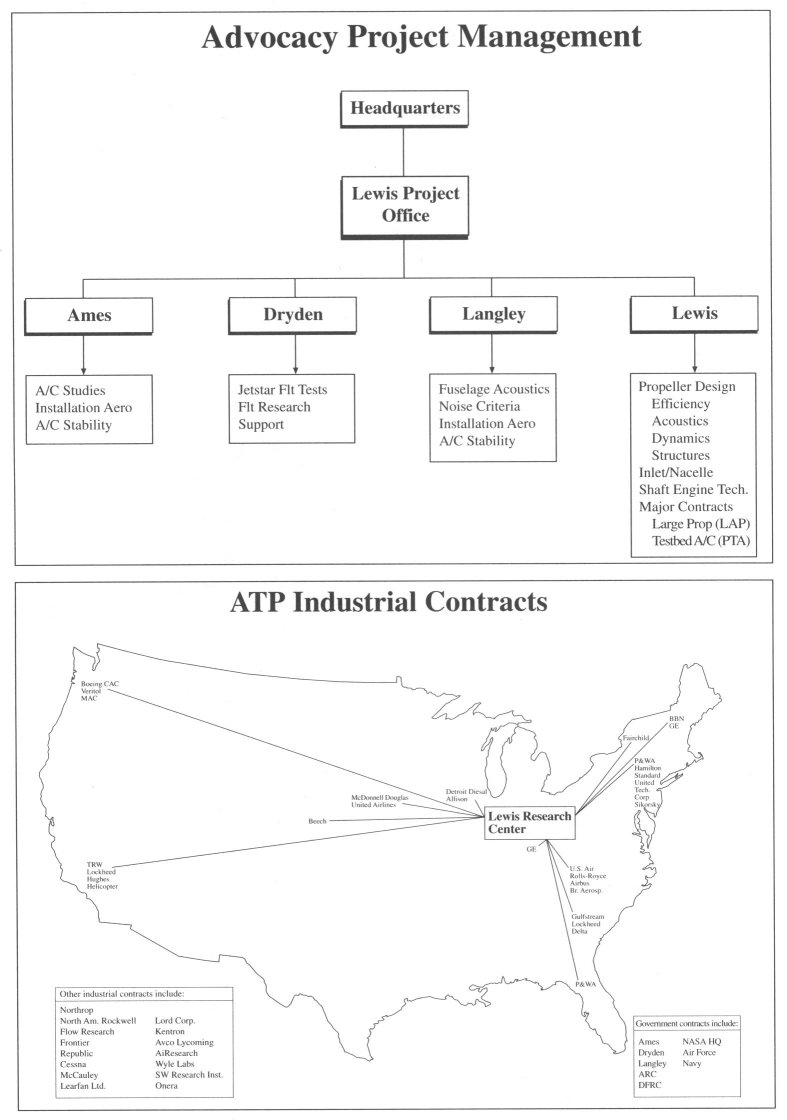

As the lead Center for the project, NASA Lewis had full responsibility

for the management of its increasingly far-flung and complicated pieces.

Before this phase began, NASA engineers devised a detailed "management

approach" and the plan was approved in 1977. Officially, Lewis was to have

"responsibility to execute all detailed project planning documentation,

develop and implement the procurement of components and systems, provide

technical direction to contractors, perform contract administration, perform

engineering functions, coordinate the related in-house research and technology

programs, and exercise the usual project review reporting and control functions."47

These interrelated activities put Lewis in the middle of an intricate web

of government (other NASA Centers), industry, and academic contracts. Project

managers were responsible for assigning the technology contracts. They

also had the equally important function of ensuring that both the public

and the government viewed the ATP positively.

40. Donald L. Nored and Frank D. Berkopec, "Guidelines for Advocacy

of the New Programs in the Aeronautics Directorate," unpublished report,

January 1981, Nored papers, NASA-Lewis Research Center, file Nored/Berkopec,

box 238, p. 1

.

41. Ibid., p. 10.

42. Ibid.

43. J. E. Wikete, Aircraft Accident Information, August 4,1976, Nored

papers, NASA, box 224.

44. Paul J. McKenna (Lewis Research Center) to Wikete, July 12,1976,

Noted papers, NASA, box 224.

45. R.M. Levintan (Hamilton Standard) to Wikete, July 27, 1976, Nored

papers, NASA, box 224.

46. P.C. Stolp (Detroit Diesel Allison) to P. Christman, July 14, 1976,

Nored papers, NASA, box 224.

47. Project Plan for the Advanced Turboprop Program, September 1977,

NASA, Noted papers, box 229, p. 26.

334 THE ADVANCED TURBOPROP PROJECT

FROM ENGINEERING SCIENCE TO BIG SCIENCE 335

Once the management structure was in place, the technology studies could

begin. Technically, this phase dealt with four critical problems: modification

of propeller aerodynamics, cabin and community noise, installation aerodynamics,

and drive systems.48 Propeller aerodynamic

work included extensive investigations of blade sweep, twist, and thickness.

The late 1970s was the first time that engineers used a high speed computer

to analyze the design of a propeller. Computers were not yet in widespread

use when the turbofan replaced propeller-powered planes in the 1950s. Lewis

programmers used their Cray supercomputers to develop the first three-dimensional

propeller aerodynamic analysis, A further structural and aerodynamic achievement

was to use thinner titanium blades to reduce the flutter problems associated

with the steel propeller blades used in the 1940s and 1950s.

The advantage of propellers to save fuel had to be balanced against

the potential harm to the environment their noise caused.49

New computer-generated design codes not only contributed to improved propeller

efficiency, but contributed to solving problems associated with noise.

Engineers closely monitored the effect of propeller noise on both cabin

occupants and people on the ground. To study propeller acoustics, they

mounted propeller models on a JetStar aircraft fuselage at the NASA Dryden

facility. Microphones located on the airframe and also on a Learjet chase

plane provided data at close range and at a distance. After reviewing the

sound pattern data, they concluded that substantial

48. Donald L. Nored, John B. Whitlow, Jr., William C. Strack, "Status

Update of the NASA Advanced Turboprop Project," unpublished report, Noted

papers, pp. 4-10.

49. Aircraft Fuel Conservation Technology, task force report, September

10, 1975, p. 18.

336 THE ADVANCED TURBOPROP PROJECT

noise reduction technology was necessary to meet the established goals.

Eventually, they achieved a reduction of sixty to sixty-five decibels of

noise through a combination of structural advances and flight path modifications.

The final two technical problems of the enabling phase dealt with installation

aerodynamics and the drive system. Numerous installation arrangements were

possible for mounting the turboprop on the wing. Should the propeller operate

by "pushing" or "pulling" the aircraft? How should the propeller, nacelle,

and the wing be most effectively integrated to reduce drag and increase

fuel efficiency? Wind tunnel tests were able to reduce drag significantly

by determining the most advantageous wing placement for the propeller.

Engineers also examined various drive train problems, including the gearboxes.

Solutions to all the enabling phase technical problems was still not

enough to guarantee the continued funding of the program. Key social questions

were still associated with this controversial technology. A vital concern

for the advanced turboprop project managers was the social question concerning

passengers: how receptive would they be to propeller-driven aircraft? In

1975, a government panel reported that they were "generally opposed to

the turboprop aircraft, primarily because they felt that there would be

little or no public acceptance." 50

If the public would not fly in a turboprop plane, all the potential fuel

savings would be lost flying empty planes across the country.

In response to this concern, NASA and United Airlines initiated an in-flight

questionnaire to determine customer reaction to propellers. Both NASA and

industry were aware of the disastrous consequences for the future of the

program if this study found that the public was against the return of propeller

planes. As a result, the questionnaire de-emphasized the propeller as old

technology and emphasized the turboprop as the continuation and advancement

of flight technology. The first page of the survey consisted of a letter

from the United Airlines vice president of marketing to the passenger asking

for cooperation in a "joint industry-government study concerning the application

of new technology to future aircraft."51

This opening letter did not mention the new turboprops. The turboprop,

inconspicuously renamed the "prop-fan" to give it a more positive connotation,

did not make its well-disguised appearance until page four of the survey

where the passenger is finally told that "'prop-fan' planes could fly as

high, as safely, and almost as fast and smooth as jet aircraft." This was

a conscious rhetorical shift from the term "propeller" to "prop-fan" to

disassociate it in peoples' minds from the old piston engine technology

of the pre-jet propulsion era. Brian Rowe, a General Electric vice president

with oversight of the advanced propeller projects, explained this new labeling

strategy. He said, "They're not propellers. They're fans. People felt that

modern was fans, and old technology was propellers. So now we've got this

modern propeller which we want to call a fan."52

The questionnaire explained to the passenger that not only did the "'prop-fans'

... look more like fan blades than propellers," they would also use twenty

to thirty percent less fuel than jet aircraft.

The questionnaire then displayed three sketches of planes-two were propeller

driven and the third was a turbofan. The passenger had to choose which

one he or she would "prefer to travel in." Despite all the planes being

in-flight, the sketches depicted the propellers as simple circles (no blades

present), while the individual blades of the turbofan were visible. These

were all subtle and effective hints to the passenger that the "prop-fan"

was nothing new and that they were already flying in planes powered by

engines with fan blades.

50. George M. Low to Alan Lovelace, April 28, 1975.

51. United Airlines Passenger Survey, NASA, Nored papers, box 224.

52. Quoted by Martha Hamilton, "Firms Give Propellers a New Spin: GE

leads high-stakes competition for aircraft engineers with its 'fan,"' The

Washington Post, February 8, 1987, p. H4, column 1.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 337

Not surprisingly, the survey yielded favorable results for the turboprop.

Of 4,069 passengers surveyed, fifty percent said that they "would fly prop-fan,"

thirty-eight percent had "no preference," and only twelve percent preferred

a jet.53 If the airlines could avoid

fare increases due to the implementation of the turboprop, eighty-seven

percent of the respondents stated they would prefer to fly in the new turboprop.

Relieved and buoyed by the results, NASA engineers liked to point out that

most of the passengers did not even know what propulsion system was currently

on the wing of their aircraft.54 According

to Mikkelson, all the passengers wanted to know was "how much were the

drinks, and how much was the ticket."55

Equally relieved was Robert Collins, vice president of engineering for

United Airlines, who concluded that this "carefully constructed

passenger survey ... indicated that a prop-fan with equivalent passenger

comfort levels would not be negatively viewed, especially if it were recognized

for its efficiency in reducing fuel consumption and holding fares down."56

At times project management also involved informing and changing government

opinion. Aeronautics programs within NASA, because of the low levels at

which they were traditionally funded, had never required close oversight

by the General Accounting Office (GAO). The large budget and greater visibility

of the Aircraft Energy Efficiency Program (ACEE) suddenly brought it unwanted

attention. The first draft of the General Accounting Office's 1979 review,

though generally favorable toward the ACEE program, was highly critical

of the advanced turboprop project. It concluded with the statement that

the "GAO believes that much of the fuel savings under ACEE attributed to

the turboprop will not be realized. "57

The draft's "negative tone" and "misleading and distorted view of the

program" deeply concerned NASA Lewis project managers who feared the repercussions

it would have on funding decisions.58

They quickly went on the attack. Center Director John Klineberg heatedly

responded that the GAO had treated the turboprop project unfairly in comparison

with the other aircraft efficiency projects, calling the GAO ignorant of

the project's "inherent uncertainties."59

NASA Lewis project managers prevailed in the battle against the negativity

of the GAO draft report. The final publication specifically contained a

retraction. The "GAO carefully reevaluated its presentation and made appropriate

adjustments where it might be construed that the tone was unnecessarily

negative or the data misleading." An example of these "appropriate adjustments"

is apparent in a comparison of how one sentence changed from the draft

to the final version. In the draft, the sentence appeared as: "The Task

Force Report shows that in 1975 there was considerable disagreement on

the ultimate likelihood of a turboprop engine being used on commercial

airliners."60 In the final publication,

the GAO amended the same sentence to: "The possible use of turboprop

53. Prop-Fan, survey results, December 1978, NASA, Nored papers, box

231.

54. Interview with Keith Sievers, August 17, 1995, and telephone interview

with Raymond Colladay, August 17 , 1995, by Virginia Dawson and Mark Bowles.

55. Mikkelson interview.

56 - Authors' italics. Robert C. Collins statement submitted to subcommittee

on transportation, aviation, and materials, House of Representatives Committee

on Science and Technology, February 26, 1981.

57. Preliminary draft of a proposed report, review of NASA's Aircraft

Energy Efficiency Project, GAO office, August 1979, Nored papers, box 182,

p. 36.

58. Unknown NASA Headquarters administrator to J. H. Stolarow, January

24, 1980, NASA, Nored papers, box 182, file GAO report.

59. John M. Klineberg to NASA Headquarters, December 21, 1979, NASA-Lewis

Research Center, Nored papers, box 182, file GAO report.

60. Preliminary draft of a proposed report, review of NASA's Aircraft

Energy Efficiency Project, GAO office, August 1979, Nored papers, box 182,

p. 37.

338 THE ADVANCED TURBOPROP PROJECT

engines on 1995 commercial aircraft is still uncertain, but has gained

support since 1975."61 These editorial

changes giving the report a positive spin indicate the effectiveness of

project managers in changing public opinion. Everyone, it seemed, had begun

to associate the advanced turboprop technology with the possibility of

bringing about an aeronautical "revolution," a paradigm shift, or as Forbes

magazine headlined in 1984, "The Next Step." As surely as 'jets drove propellers

from the skies," the new "radical designs" could bring a new propeller

age to the world.62

It is important to underscore how important the interpersonal skills

of the project managers were to continuation of the program throughout

this enabling technology phase. They were responsible not only for managing

the project's technology, but also for enabling, proving, maintaining,

and adjusting support for the turboprop. They continued to push this controversial

technology against the conservative interests of the government, industry,

and the public. Their consistent success paved the way for the third stage.

Large-Scale Integration and Competition

After two years of work, the advanced turboprop idea began to attract

greater commercial interest. As a result of NASA's advocacy efforts, news

articles began to predict the coming propeller "revolution." All indicators

pointed to the introduction of the new turboprops on commercial aircraft

by the 1990s. With the small-scale model testing complete, a data base,

and an acceptable design methodology established, the project moved into

its most labor and cost intensive phase that of large-scale integration.

The project still had serious uncertainties and problems associated with

transferring the designs from a small-scale model to a large-scale prop-fan.

Could engineers maintain propulsion efficiency, low noise levels, and structural

integrity with an increase in size? The Large-Scale Advanced Prop-fan (LAP)

project initiated in 1980 would answer these scalability questions and

provide a database for the development and production of full-size turbofans.

As a first step, NASA had to establish the structural integrity of the

advanced turboprop.63 Project managers

initially believed that in the development hierarchy performance came first,

then noise, and finally structure. As the project advanced, it became clear

that structural integrity was the key technical problem.64

Without the correct blade structure, performance could never achieve predicted

fuel savings. NASA awarded Hamilton Standard the contract for the structural

blade studies that were so crucial to the success of the whole program.

In 1981, they began to design a large-scale, single-rotating prop-fan made

of composite material. Five years later they completed construction on

a 9-foot-diameter design very close to the size of a commercial model.

The model was so large that no wind tunnel in the United States could accommodate

it. The turboprop managers decided to risk the possibility that the European

aviation community might benefit from the technology that NASA had so arduously

perfected. They shipped the large-scale propeller, called the SR-7L, to

a wind tunnel in Modane, France, for testing. In early 1986, researchers

subjected the model to speeds up to Mach 0.8 with simulated altitudes of

12,000 feet. The results confirmed the data obtained from the small model

propeller designs. The large-scale model was a success.

61. "A look at NASA's Aircraft Energy Efficiency Program," by the Comptroller

General of the United States, July 28, 1980, Nored papers, box 182, file

GAO report, p. 45.

62. Howard Banks, "The Next Step," Forbes, May 7, 1984, p. 31.

63. "Large-Scale Advanced Prop-Fan Program (LAP)," technical proposal

by Lewis Research Center, January 11, 1982, NASA, Noted papers, box 229.

64. Noted interview.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 339

Success spawns imitators. While NASA continued to work with Allison,

Pratt & Whitney and Hamilton Standard to develop its advanced turboprop,

General Electric (GE)Pratt & Whitney's main competitor was quietly

developing an alternative propeller system. A feature of radical inventions

is that competitors often introduce alternative forms of a similar technology

before one form can prevail over another. Historians of technology have

shown many cases of "interpretative flexibility" when "two or even more

social groups with clearly developed technological frames [artifacts] are

striving for dominance in the field."65

This happened when General Electric introduced its own radical alternative

to NASA's advanced turboprop project-the Unducted Fan (UDF). GE sprang

the unducted fan on NASA completely by surprise.

In NASA's design, the propeller rotated in one direction. This was called

a single rotation tractor system and included a relatively complicated

gearbox. Since one of the criticisms against the turboprop planes of the

1950s (the Electra, for example), was that their gearboxes required heavy

maintenance, GE took a different approach to prop-fan design. Beginning

in 1982, GE engineers spent five years developing a gearless, counter-rotating,

pusher system. They mounted two propellers (or fans) on the rear of the

plane that literally pushed it in flight, as opposed to the "pulling" of

conventional propellers. In 1983, the aircraft engine division of General

Electric released the unducted fan design to NASA shortly before flight

tests of the NASA industry design were scheduled. Suddenly there were two

turboprop projects competing for the same funds. Nored recalled: "They

wanted us to

65. Wiebe E. Bijker, "The Social Construction of Bakelite: Toward a

Theory of Invention," The Social Construction of Technological Systems,

182.

340 THE ADVANCED TURBOPROP PROJECT

drop everything and give them all our money and we couldn't do that."66

NASA Headquarters endorsed the "novel" unducted fan proposal and told NASA

Lewis to cooperate with General Electric on the unducted fan development

and testing.

Despite NASA's initial reluctance to support two projects, the unducted

fan proved highly successful. In 1985, ground tests demonstrated a fuel

conservation rate of twenty percent.67

Development of the unducted fan leapt ahead of NASA's original geared design.

One year later, on August 20, 1986, GE installed its unducted fan on the

right wing of a Boeing 727. Thus, to many NASA engineers' dismay, the first

flight of an advanced turboprop system demonstrated the technical feasibility

of the unducted fan system a proprietary engine belonging entirely to

General Electric, rather than the product of the joint NASA/industry team.

Nevertheless, the competition between the two systems, and the willingness

of private industry to invest its own development funds, helped build even

greater momentum for acceptance of the turboprop concept.

NASA engineers continued to perfect their single-rotating turboprop

system through preliminary stationary flight testing.68

The first step was to take the Hamilton Standard SR-7A propfan and combine

it with the Allison turboshaft engine and gearbox housed within a special

tilt nacelle. NASA engineers conducted a static or stationary test at Rohr's

Brown Field at Chula Vista, California, where they mounted the nacelle,

gearbox, engine, and propeller on a small tower. The stationary test met

all performance objectives after fifty hours of testing in May and June

1986. This success cleared the way for an actual flight test of the turboprop

system. In July 1986 engineers dismantled the static assembly and shipped

the parts to Savannah, Georgia, for reassembly on a modified Gulfstream

II with an eight-blade, single-rotation, turboprop on its left wing.69

The radical dreams of the NASA engineers for fuel efficient propellers

were finally close to becoming reality. The plane contained over 600 sensors

to monitor everything from acoustics to vibration. Flight testing-the final

stage of advanced turboprop development-took place in 1987 when a modified

Gulfstream II took flight in the Georgia skies. These flight tests proved

the predictions of a twenty to thirty percent fuel savings (made by NASA

in the early 1970s) were indeed correct.

On the heels of the successful tests, of both the GE and the NASA-industry

team designs, came not only increasing support for propeller systems themselves,

but also high visibility from media reports forecasting the next propulsion

revolution. The New York Times predicted the "Return of the propellers"

while a Washington Times headline read, "Turboprops are back!"70

Further testing indicated that this propulsion technology was ready for

commercial development. As late as 1989, the U.S. aviation industry was

"considering the development of several new engines and aircraft that may

incorporate advanced turboprop propulsion systems."71

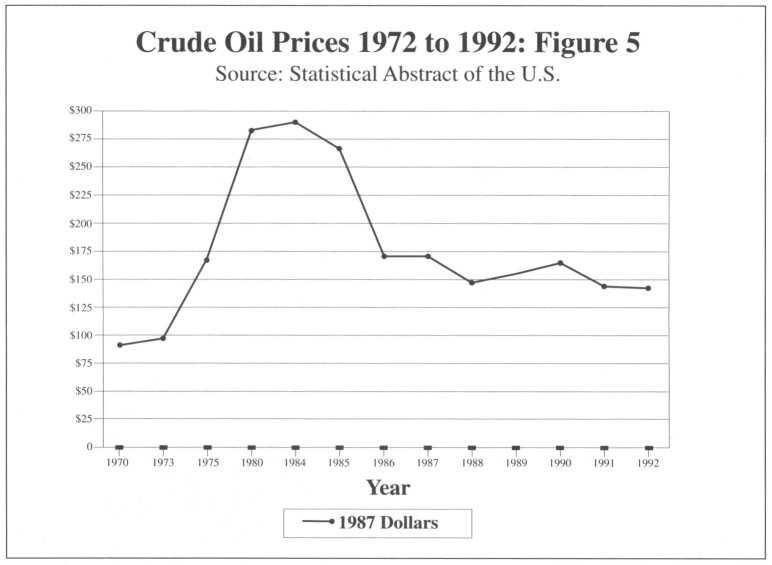

But the economic realities of 1987 were far different from those predicted

in the early 1970s. Though all the technology and social problems standing

in the way of commercialization were resolved, the advanced turboprop never

reached production, a casualty of the one contingency that NASA engineers

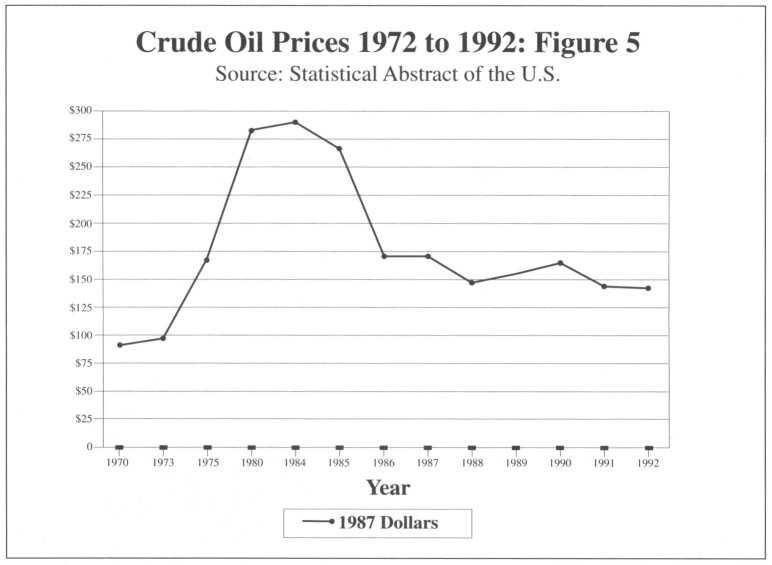

never anticipated that fuel prices would go down. (See figure 5) Once

the energy crisis passed, the need for the advanced turboprop vanished.

66. Noted interview.

67. James, J. Haggerty, "Propfan Update," p. 11.

68. Hagar and Vrabel, Advanced Turboprop Project, pp. 49-74.

This stage was called the Propfan Test Assessment (PTA) Project.

69. Mary Sandy and Linda S. Ellis, "NASA Final Propfan Program Flight

Tests Conducted," NASA News May 1, 1989.

70. Andrew Pollack, "The Return of Propellers," The New York Times,

October 10, 1985, D2. Hugh Vickery, "Turboprops are back!," The Washington

Times, November 1, 1984, p. 5B.

71. Mary Sandy and Linda S. Ellis, "NASA Final Propfan Program Flight

Tests Conducted," NASA News May 1, 1989.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 341

Environmental Contingency and Insufficient Momentum

One of the main difficulties in the development of a radical new technology

is the potential project threatening problems that arise. If they are left

unsolved they can destroy an entire project. Historian of technology Thomas

Hughes called these problems "reverse salients." Hughes argues that all

large technological systems (of which the turboprop is an example) include

political, economic, social, and technological components.72

These system components are interrelated so that if one of the components

is changed or altered in any way, the rest of the system will also be affected.

The systems themselves grow and gain momentum by the process of removing

"reverse salients," which arise and could potentially cause the system

to fail. An example will help clarify the importance of solving these critical

problems. In 1878, Thomas Edison encountered a technological reverse salient

in his attempt to develop his electric-lighting system. This problem was

the short-lived filament of the incandescent bulb. Edison realized that

even if he solved this problem, a further economic reverse salient remained.

The expense of the copper wire needed to link the entire system together

was cost prohibitive for potential wide-scale acceptance. If Edison could

not reduce the amount of copper needed for his electric system, then gas-lighting

systems would become the more attractive alternative to the problem of

street lighting. What is important to understand is that either the technological

or the economic reverse salient could have caused the Edison system of

electric-lighting to fail.73

Like Edison, the managers of the turboprop project also confronted a

variety of critical problems. These problems included economic (the necessity

of maintaining a favorable ratio of cost to implement turboprop technology

versus savings in fuel efficiency), political (how to receive funding for

a long-term project), social (how to implement a technology which the public

could perceive as a "step backward"), institutional (how to successfully

manage the government, industry, and academic relations), and technical

(how to actually build a turboprop that improved fuel efficiency by twenty

to thirty percent). Each of these problems had the potential to sabotage

the entire system. NASA engineers had their own, more practical and direct

term for "reverse salient" a "showstopper." In 1984, engineers listed

a number of technical show-stoppers that threatened to derail the project

if left unsolvedfor example, unacceptable levels of cabin noise.74

As system-builders solve critical problems, the system itself generates

momentum. This momentum continues to increase and build until, according

to Hughes, either a conversion, a catastrophe, or a contingency occurs.

Conversions and catastrophes break momentum through either a change in

societal belief, like a religious conversion, or a massive technological

failure, like a nuclear-reactor catastrophe. But, it is the role of contingency

which interests us here as the key factor in the current neglect of the

advanced turboprop technology. Hughes identified one particular "contingent

environmental change" that altered the course of the entire automobile

industry the energy crisis. He argues, "The oil embargo of 1973 and the

subsequent rise in gasoline prices ultimately compelled U.S. automobile

manufacturers to change substantially an automobile design that had been

singularly appropriate to a low-cost-energy environment."75

72. Thomas P. Hughes, Networks of Power Electrification in Western

Society, 1880-1930 (Baltimore, MD: The Johns Hopkins University Press,

1983).

73. Hughes, American Genesis: A Century of Invention and Technological

Enthusiasm (London, England: Penguin Books, 1989), pp. 71-74.

74. Chart entitled, "Potential show-stoppers," February 6, 1984, NASA-Lewis

Research Center, Noted papers, box 239, file ATP memos.

75. Ibid., p. 462.

342 THE ADVANCED TURBOPROP PROJECT

The development and subsequent neglect of advanced turboprop technology

is the result of this same environmental contingency. In the early 1970s,

the energy crisis created a situation which made it a national necessity

for the government to explore new ways to conserve fuel. What the managers

of the Advanced Turboprop Project (ATP) did not anticipate and could not

control was a decrease in the cost of fuel. As the energy crisis subsided

in the 1980s and the fuel prices decreased, there was no longer a favorable

ratio of cost to implement turboprop technology versus savings in fuel

efficiency. As John R. Facey, advanced turboprop program manager at NASA

Headquarters, wrote, "An all new aircraft with advanced avionics, structures,

and aerodynamics along with high-speed turboprops would be much more expensive

than current turbofan-powered aircraft, and fuel savings would not be enough

to offset the higher initial cost."76

In the case of the ATP, its managers overcame all of their critical problems.

However, when contingent economic conditions changed so that fuel cost

was no longer a critical problem, regardless of the technical success of

the project, the advanced turboprop lost its potential market in the industrial

world.

Yet Keith Sievers, at that time the manager of the ATP, along with a

handful of project staff, was convinced that the NASA industry team had

made a significant contribution to aviation that ought to receive recognition.

To win the Collier Trophy, he again summoned up the advocacy skills that

had proved so valuable in bringing the controversial advanced turboprop

to the point of technical feasibility. He used them to lobby for the prestigious

Collier Trophy among the wide aeronautical constituency that had participated

in advanced turboprop development. NASA Headquarters initially expressed

some reluctance to lobby for awarding a prize for technology that was unlikely

to be used at least in the near future. But the timing was perfect. There

was little competition from NASA's space endeavors since staff in the space

directorate were still in the midst of recovering from the tragic Challenger

explosion.

As a result, the National Aeronautic Association awarded NASA Lewis and

the NASA Industry Advanced Turboprop Team the Collier Trophy at ceremonies

in Washington, DC. Today, the technology remains "on the shelf," or "archived,"

awaiting the time when fuel conservation again becomes a necessity.77

Despite the current neglect of the advanced turboprop, this case study

demonstrates how radical innovation can emerge from within a conservative,

bureaucratic government agency. The governmentnot industryassumed the

risk for developing the new technology. It used taxpayers' money to advance

a radical idea to the point of technical feasibility. Engineers involved

in the project used advocacy to build a consensus among the members of

the aeronautical community that the advanced turboprop would prove a viable

alternative to the far less energy efficient turbofan technology. Indeed,

the technical and social achievements of the project were convincing enough

to drive General Electric to invest its own funds to develop a competing

design. This competition was evidence of wide acceptance for the turboprop

concept.

The Collier Trophy in 1987 was presented to the "Lewis and the NASA

Industry Advanced Turboprop Team.'' The team, defined in its widest possible

context, included General Electric's independent contribution of the UDF

and its subsequent flight testing by NASA. In contrast to previous Collier

trophies in aeronautics won by the NACA, no individual received special

mention. Certainly, throughout the eleven years of its existence the project

had encouraged inventiveness of individuals in a variety of disciplines,

from highly theoretical contributions in blade design and acoustics to

more routine testing.

76. John R. Facey, "Return of the Turboprops," Aerospace America

(October 1988): 15.

77. Some specific technologies generated by the ATP project are in

use today. These include noise reduction advances, gearboxes that use the

ATP design, and certain structural advancements, for example, how to keep

the blades stable, used in engine designs today, including large, high

by-pass ratio turbofans of the 1990s. Sievers interview.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 343

Participants in the project ran the gamut from government, university,

and industry researchers. But what the prize recognized above all was the

project's management genius. NASA Lewis managers did not simply manage

contracts. They kept the project alive. They used advocacy to win industry

participation and cooperation, as well as stimulate competition. They pushed

both the technical and the social aspects of the project to create the

system's momentum. Yet once the energy crisis passed, this momentum was

insufficient to dislodge the massive technological momentum of the existing

turbofan system.

NASA engineers involved in the ATP project still remain confident that

the future economic conditions will make the turboprop attractive again.

When fuel becomes scarce and fuel prices begin to rise, the turboprop's

designs will be "on the shelf' ready to respond with tremendous fuel-efficient

savings. But, technological neglect is not the enthusiastic success on

which NASA engineers built their careers. Donald Nored wistfully reflected

on the project and said, "We almost made it. Almost made it."78

78. Noted interview.