By Linda Herridge

NASA’s John F. Kennedy Space Center

When NASA’s new heavy-lift rocket, the Space Launch System (SLS), soars from its launch pad at Kennedy Space Center in 2018 with the Orion spacecraft, its powerful solid rocket boosters will generate more than 75 percent of the thrust at liftoff to help the massive launch vehicle escape Earth’s gravity. Several major structures of the five-segment solid rocket boosters — the largest ever built for flight — are being prepared for the rocket’s first mission with Orion.

SLS booster prime contractor Orbital ATK is performing the work for the first flight of the rocket at the Hangar AF complex at Cape Canaveral Air Force Station in Florida, as well as at several other specialized facilities at the Kennedy Space Center. The large hangar and several support buildings provide the capabilities required to reuse previously flown booster flight hardware.

“Processing hardware for the first SLS flight is incredibly exciting and rewarding,” said Rick Serfozo, Orbital ATK Florida Operations site director. “Every day, the team is hands-on meeting challenges and solving technical problems.”

The first launch of an uncrewed Orion spacecraft atop the SLS rocket is targeted for late 2018. The test mission will soar into space from Launch Pad 39B at the agency’s Kennedy Space Center in Florida. Parts of the right and left booster structures for the SLS rocket currently are being readied for this first flight.

Technicians started by working on the bottom parts of the boosters, known as the aft skirts. These contain the system that steers the boosters, the motors that separate them from the rocket, and other controls. These aft skirts, and other booster structures stored in the hangar and the Booster Fabrication Facility, were used on space shuttle missions.

Orbital ATK engineers, technicians and quality assurance personnel all have roles in helping to prepare some of the SLS booster structures for its mission. The SLS Program then “hands over” the booster structures to the Ground Systems Development and Operations Program at Kennedy, which is responsible for integrating the booster assemblies and then stacking, or building up, the entire rocket.

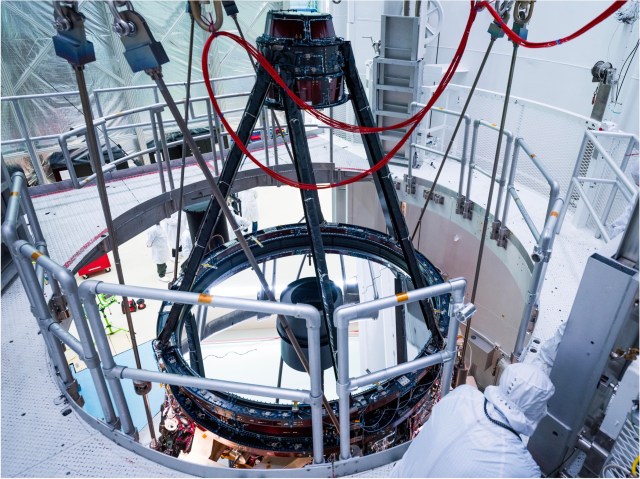

Inside another specialized facility, the Multi-Media Blast Facility, each aft skirt was blasted with tiny plastic and glass beads to remove old paint, primer and sealants in order to expose bare metal. Technicians used non-destructive evaluation techniques, including X-ray, ultrasonic and eddy-current testing, to painstakingly inspect the aft skirts for defects. If found, defects were marked and repaired.

Inside the Surface Prep Facility, the aft skirts went through a thorough cleaning and surface preparation process prior to receiving primer and topcoat paint. One at a time, the skirts were transferred to a paint booth where skilled technicians precisely applied primer and then polyurethane-based paint.

After the paint was cured and tested, the left aft skirt was transported to the Booster Fabrication Facility to begin the assembly process. The right aft skirt soon followed.

The forward skirts, frustums and associated hardware also will be refurbished at the hangar. These structures comprise the top portion, or forward assembly, of the solid rocket boosters. The frustums, along with the nose cones, serve as the aerodynamic fairing for the boosters. All of the smaller parts, such as brackets and support frames required to assemble the booster subsystems, also are being refurbished in a similar manner within facilities at the hangar.

“Our Orbital ATK team is both honored and excited to support NASA in our country’s next steps in human deep space exploration with NASA’s Space Launch System as we look forward to the first launch of SLS and Orion,” Serfozo said. “Some of the next steps on NASA’s Journey to Mars are beginning right here on Florida’s Space Coast with Orbital ATK’s work on the SLS solid rocket boosters.”