By Linda Herridge

NASA’s John F. Kennedy Space Center

NASA’s Kennedy Space Center in Florida will have a busy year preparing facilities, ground support equipment and space hardware for the launch of Artemis I, the first uncrewed launch of the Space Launch System (SLS) rocket and the Orion spacecraft. In 2020, Exploration Ground Systems (EGS) activities will ramp up as launch hardware arrives and teams put systems in place for Artemis I and II missions.

Launch Countdown Simulation Activities

Launch countdown simulations will continue to ramp up in 2020 to train and certify the launch control team for Artemis missions. The types of simulations will build on one another and will walk through the final portions of the launch countdown sequence, called the terminal countdown. Integrated simulations will tie in all NASA centers working the mission to ensure all members of the team are ready to work together, including Mission Control at Johnson Space Center in Houston, and the SLS Engineering Support Center at Marshall Space Flight Center in Alabama. Simulations will begin at the end of January and will occur up through one week before launch, with an average of one training exercise each month.

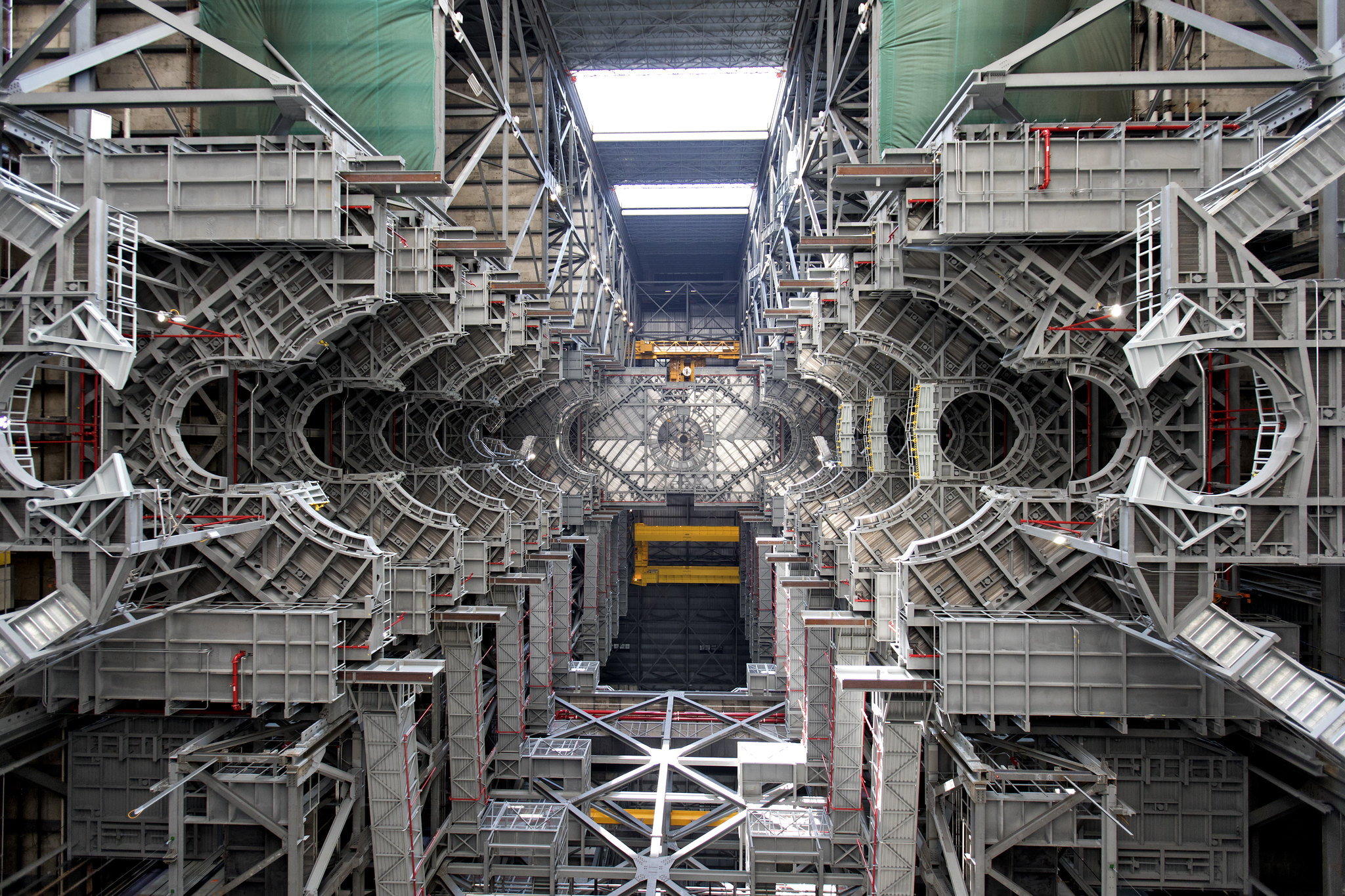

Vehicle Assembly Building

Much of the work in 2020 will be to complete a punch list of detail work inside the Vehicle Assembly Building (VAB). This includes cleaning the platforms and making minor repairs to any platform hardware that will be near flight hardware as the facility prepares for arrival of SLS components and stacking operations.

“We are at a very significant point in NASA’s Artemis mission,” said Mike Bolger, program manager of EGS. “The EGS team has finished mobile launcher testing at the launch pad and will finish testing at the VAB in January. At that point, all of the launch infrastructure will be tested and ready for operations.”

Launch Complex 39B

Teams will continue work on a new emergency egress system for Pad 39B where flight or ground crew could board a basket with a braking system at the crew access level of the mobile launcher. The crew would ride the basket down a cable and come to a stop near a bunker to the west of the pad surface, providing quick escape in the unlikely event of an emergency. The design phase began in 2019 and construction will be complete in time to support crewed Artemis missions.

The pad is currently getting a liquid hydrogen upgrade. The project involves the integration of a new 1.4 million gallon, liquid hydrogen (LH2) storage sphere into the existing Launch Complex 39B system. The new LH2 sphere will work with the current LH2 sphere to supply LH2 for Artemis II and beyond. The larger tank will allow NASA to attempt SLS launches on three consecutive days, instead of opportunities two out of three days, in the event of a scrub. The newer technology reduces liquid hydrogen burn-off, allowing more launch attempts before having to refill the larger tank. Construction began in 2019 and will be complete prior to Artemis II.

Orion Underway Recovery Test 8

The integrated recovery team of NASA, EGS, Lockheed Martin and the U.S. Navy, along with additional contractor support, will head out to sea off the coast of California in March to conduct the eighth Underway Recovery Test. Using a Navy ship with a well deck and several small boats, the primary objective is to validate Orion recovery operations for Artemis I — including procedures and timelines, and practicing different scenarios.

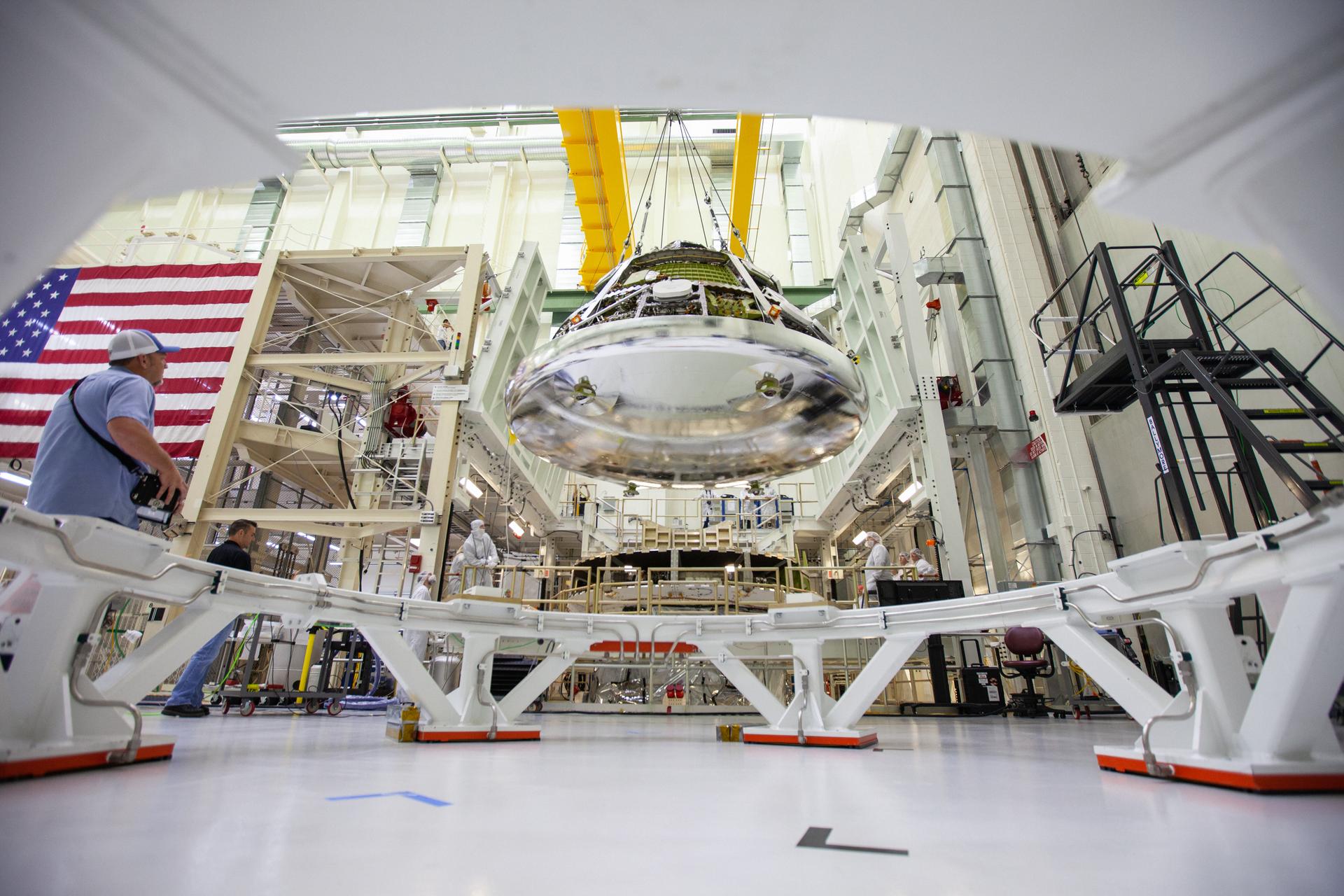

Orion Spacecraft

This spring, the Orion spacecraft for Artemis I will return from NASA’s unique test facility at Plum Brook Station in Ohio, where it is currently undergoing environmental testing inside the vacuum chamber that simulates the harsh environment of space. Inside the Neil Armstrong Operations and Checkout (O&C) Building at Kennedy, technicians will install the spacecraft’s solar array wings before performing final checkouts. EGS will begin Orion ground processing and stacking activities later in the year. The team will process and fuel Orion in the Multi-Purpose Processing Facility then transfer it over to the Launch Abort System Facility where engineers will attach the launch abort system. Orion will then roll out to the VAB for inspections before stacking Orion on top of the SLS rocket.

In its early processing stages, the Artemis II crew module milestones inside the O&C include propulsion tank installation, a pressure test and subsystems installations in the spring. The initial power-on of the crew module will occur in early fall. The heat shield that will protect the first crewed mission of Orion will be completed and installed by the end of the year. Processing and testing of the crew module adapter – the ring that connects to the European Service Module – for Artemis II will happen in the first half of the year prior to the arrival of the European Service Module in the fall.

Space Launch System

Training activities with pathfinders, or full-scale replicas, of the SLS core stage and booster segments occurred in 2019, and more training with various pathfinder segments and hardware will continue. In 2020, training will involve stacking inert booster segments on the mobile launcher in the VAB.

Hardware for SLS will continue to arrive for processing and integration in various Kennedy facilities. This year all ten of the solid propellant booster segments will arrive by train from their Northrop Grumman manufacturing facility in Promontory, Utah. The launch vehicle stage adapter, which will connect the SLS core stage to the interim cryogenic propulsion stage, will arrive by barge. The booster aft skirts – which contain the thrust vector control system that steers the rocket – will trek from the Booster Fabrication Facility to the Rotation, Processing and Surge Facility where they will be attached to the aft exit cones. The exit cones are attached to the bottommost part of each of the twin boosters to provide extra thrust to the boosters and protect the aft skirts from the thermal environment during launch.

The core stage of the SLS rocket will undergo a Green Run test campaign over several months in the B-2 test stand at the agency’s Stennis Space Center in Mississippi. Following Green Run completion, the 225,000-pound core stage will leave Stennis and arrive at Kennedy on the Pegasus barge. The core stage and solid rocket boosters will then be integrated inside the VAB.

Mobile Launcher 2

In 2019, NASA awarded a contract for Mobile Launcher 2 to Bechtel National Inc. of Reston, Virginia. The ground structure that will be used to assemble, process and launch the second and more powerful configuration of the SLS rocket, called Block 1B, is in its early stages of design and development and will be ready for Artemis IV.

Artemis I will be the first in a series of increasingly challenging missions that will enable human exploration to the Moon and Mars. In 2020, the mission will truly begin to take shape as hardware arrives and stacking operations begin inside the VAB.

“The operations team is writing procedures, training, and preparing for flight hardware processing,” Bolger said. “When the SLS and Orion are turned over to EGS later this year, Kennedy will be ready!”

Future Artemis missions will establish a sustainable presence at the Moon for decades to come, and Kennedy teams will move forward in 2020 to build the infrastructure and make those missions possible.