How do you learn how to build stronger, lighter rockets and spacecraft structures? Come up with a totally new design, use an innovative material, build the rocket part and then break it. That’s exactly how engineers not only learn how a structure will perform during one test, but also learn how to use high-tech models to predict how a structure will perform before it ever gets to the launch pad.

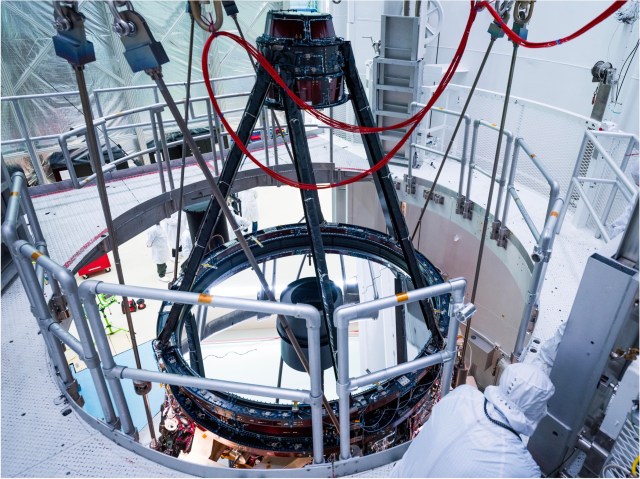

NASA successfully completed the first series of high-tech composite tests in late spring as a large cylindrical barrel was tested to failure under extreme compressive loads of almost 900,000 pounds, all in the name of building lighter, stronger primary structures for future launch vehicles.

During the testing for the Shell Buckling Knockdown Factor Project, which occurred at NASA’s Marshall Space Flight Center in Huntsville, Alabama, force was increasingly applied to the top of a composite barrel to evaluate the structural integrity of the test article. The resulting data will help engineers in the design and build of primary structures for future launch vehicles.

“Because of the team’s experience with state-of-the-art modeling techniques, we were optimistic that the barrel would perform well and that we could predict when the hardware would fail,” said Dr. Marc Schultz, research engineer in the Structural Mechanics and Concepts Branch at NASA’s Langley Research Center in Hampton, Virginia. Schultz is leading the tests for the NASA Engineering and Safety Center. “In fact, we predicted the failure load within 1 percent of the actual failure load, which was very exciting.”

Composite materials are increasingly being considered and used for launch-vehicle structures. When properly applied, composite structures have the potential to have many benefits over traditional metallic structures, including lower mass, better fatigue resistance, lower part count, and reduced life-cycle cost.

Seven tests were performed on the 8-foot-diameter, 8.4-foot-tall graphite-epoxy, honeycomb-core sandwich composite barrel that was designed by NASA and fabricated by Northrop Grumman as part of a cooperative agreement. The barrel was outfitted with nearly 300 individual electronic strain and displacement sensors and approximately 16,000 fiber optic sensors to evaluate the structural integrity of the barrel. Additionally, special software was used with high-speed and low-speed cameras to monitor the black and white polka dot pattern and measure movement and deformation of the test article during loading.

“It’s always a bit surprising when such a sudden failure occurs,” Schultz said. “All eyes were on the test article and, even though we were expecting it, the failure still caught us off guard. The loud bang first startled us and then we saw the crack all the way around the barrel that formed almost instantaneously from the buckling event.”

This test series was the first large-scale composite test for the Shell Buckling Knockdown Factor Project, which is focused on developing and validating new analysis-based design guidelines for developing safer and lighter space structures. Designing lighter rockets will allow launch vehicles to carry larger payloads–-landers, equipment, habitats, food, water and supplies –- paramount to allow humans to travel to deep space destinations, including Mars, where quick resupply is not possible.

“Our test team learned a great deal about what to expect when testing large cylindrical composite structures during this series – such as instrumenting the structure, failure modes, and capture system after we tested to failure,” said Lucas Day, Marshall’s lead test engineer for the shell buckling efforts. “We will apply the knowledge gained to the remaining four tests planned over the next four years.”

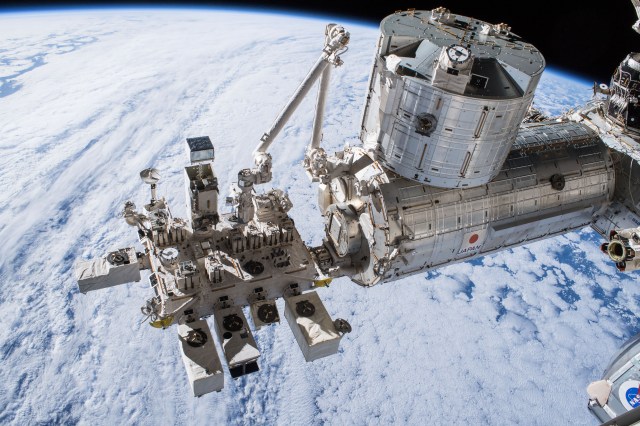

The testing was conducted at Marshall’s Load Test Annex, part of the Structural and Dynamics Engineering Test Laboratory previously used to test large structures for the Saturn V rocket, space shuttle, and International Space Station. Construction is underway at the facility on steel reaction towers and fixtures that will be used for structural loads testing on the Core Stage Intertank and Engine Section for the Space Launch System for the next era of human exploration to deep space destinations, including Mars.