In This Week’s Star

- Dragon Carries Cargo, New Experiments to International Space Station

- I Am Building SLS: Jeff Adams

- Boeing Deep Space Habitat Ground Prototype Unveiled at Marshall

- Teams 3D Print Planetary Habitats, Awarded $700K in NASA Challenge

- NASA Michoud Team Prepares Forward Join for Horizontal Assembly

- January 29, 1971: Apollo Columbia Command Module Lands in Montgomery

- Spectrabotics CEO Tim Haynie to Deliver Tech Talk on May 9

- Marshall Educator John Weis Shares NASA Messages with Illinois Students

- Marshall Talks Space with Students on Mission Control: Human Spaceflight

- This Week in NASA History: Uprated J-2 Engine Arrives at Marshall – May 6, 1966

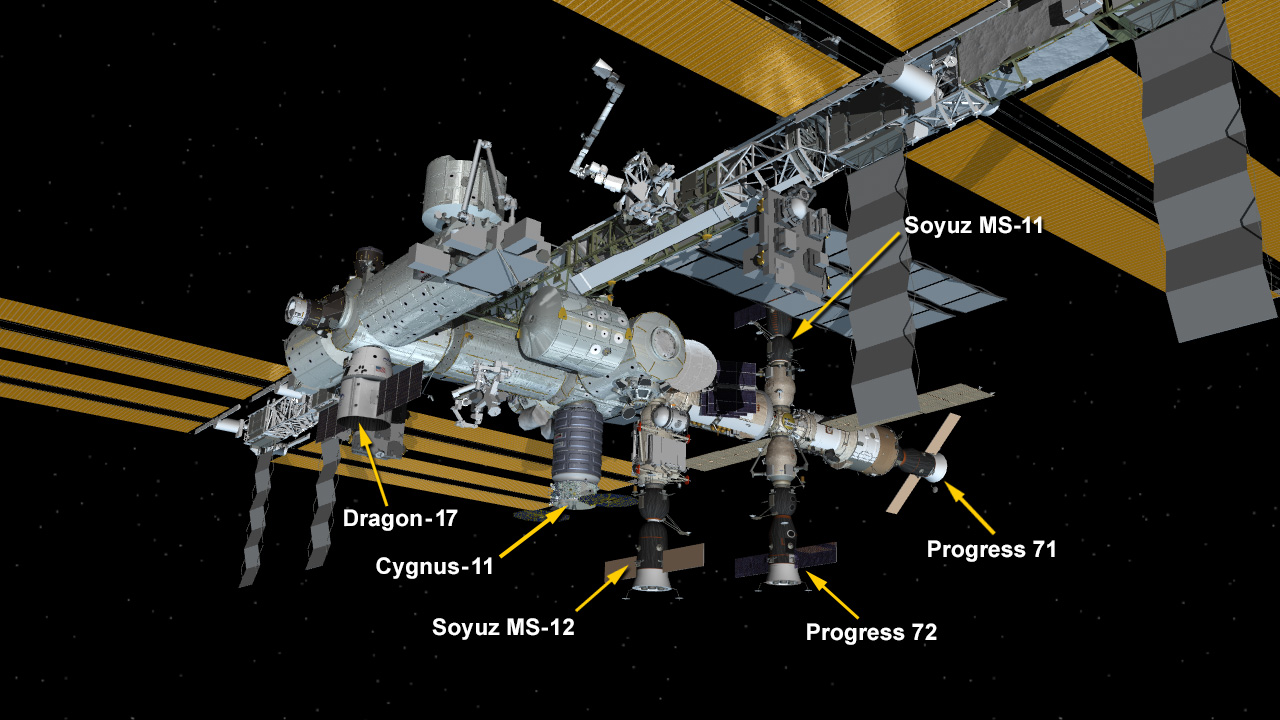

Dragon Carries Cargo, New Experiments to International Space Station

New science investigations and 5,500 pounds of cargo are being unpacked by astronauts onboard the International Space Station, delivered in a Dragon resupply capsule carried by SpaceX. Dragon will remain at the space station for approximately one month.

Launched May 4 from Cape Canaveral Air Force Station, the spacecraft was captured by station astronauts and berthed to the orbiting outpost using the station’s robotic arm on May 6.

Among the newly arrived experiments are tissue chips and the Hermes facility.

Tissue chips is an experiment to determine if it is possible to predict the effectiveness of potential medicines in humans. The chips mimic the function of human organs. As simulated blood – which can carry medicine or toxins – passes through the chip, scientists can study changes to the cells in the chips resulting from the simulated blood. The microgravity environment shows signs of having advanced aging effects on astronauts, so data that would take months to collect in a lab on Earth can be collected in just a few weeks in space.

The Hermes facility will enable Earth-based scientists to study how particles of regolith – the surface layer of the Moon, Mars and asteroids – behave in microgravity over long periods of time. Changes in the particles due to pressure, temperature and impacts will also be studied, providing insights into the formation of the solar system.

The Payload Operations Integrations Center at NASA’s Marshall Space Flight Center coordinates all U.S., European, Japanese and Canadian scientific and commercial experiments on the station, synchronizes payload activities of international partners and directs communications between station crew and researchers around the world with onboard experiments.

Keep up with the International Space Station, and its research and crews here.

I Am Building SLS: Jeff Adams

The trip back to the Moon for America’s space program begins right here on the ground.

I’m a civil engineer who spent part of my childhood in Titusville, Florida, watching the historic Apollo program launches. My father worked for Boeing, fueling the first stages of the Saturn launch vehicles. Now, I’m helping lay a solid foundation for NASA’s astronauts to return to the Moon by 2024 by working with a team that’s responsible for transporting some of the largest rocket hardware ever built.

You see, before NASA’S Space Launch System soars from the launch pad, NASA needs to test full-scale replicas of the rocket’s components to give engineers real-world data to verify their computer models. This rocket will take astronauts back to the Moon for the first time since I watched Apollo 17 lift off in 1972, so it has to be safe and it has to be right.

That’s where my team, the Logistics Engineering and Transportation Team, comes in. We work behind the scenes to move full-scale core stage test hardware from NASA’s rocket factory, Michoud Assembly Facility, to test facilities at Marshall Space Flight Center.

Each move has to be meticulously planned. The team spends months planning and developing detailed transportation move procedures to ensure the test articles are delivered without a mishap. The team also develops contingency plans, just in case.

So far, my team has safely transported three test articles to their test fixtures: the engine section, the intertank and the enormous liquid hydrogen tank.They were moved using three pieces of ground support equipment: the Engine Section Transporter, the Multipurpose Transportation System and NASA’s barge, Pegasus. Next, we’ll move the liquid oxygen tank structural test article.

The core stage test hardware may be the size of building — a small or large building, depending on which component we’re talking about — but sometimes the clearance is tight to get a test article onto Pegasus and into the test stand. The team analyzes the data and runs the numbers repeatedly. Their attention to detail is unmatched. Even so, when the hardware finally rolls onto the barge and then into the test stand, we all feel a great sense of accomplishment. There are high-fives and fist-bumps all around, then it’s right back to work planning the next move.

On the day SLS and NASA’s Orion spacecraft launch, you might not think about the ground support equipment or the logistics and coordination involved in transporting large test articles. My team will be watching the fruits of our behind-the-scenes labor, though. The equipment and procedures we’ve built are laying the foundation of a new generation of spaceflight — and that makes this civil engineer proud!

Boeing Deep Space Habitat Ground Prototype Unveiled at Marshall

A new, deep space habitat ground prototype was unveiled at a May 1 event for local media at NASA’s Marshall Space Flight Center. Boeing’s Exploration Habitat Demonstrator, to undergo testing at Marshall this summer, is one of five uniquely designed prototypes in development through NASA’s Next Space Technologies for Exploration Partnerships, or NextSTEP. Testing the prototypes will help NASA determine its requirements to procure a habitation module for the lunar Gateway — the first spacecraft designed to stay in orbit around the Moon, enabling new lunar exploration and science missions, and supporting future missions to Mars. (Boeing)

Teams 3D Print Planetary Habitats, Awarded $700K in NASA Challenge

After 30 hours of 3D printing over four days of head-to-head competition, NASA and partner Bradley University of Peoria, Illinois, awarded $700,000 to two teams in the final round of the 3D-Printed Habitat Challenge. The top prize of $500,000 was awarded to New York-based AI. SpaceFactory. Second place and $200,000 was awarded to Pennsylvania State University of University Park.

The teams faced off May 1-4 at Caterpillar’s Edwards Demonstration & Learning Center in Edwards, Illinois, creating subscale shelters out of recyclables and materials that could be found on deep-space destinations, like the Moon and Mars. The size of the structures had to be a one-third scale version of their architectural designs. Each team employed robotic construction techniques that allowed minimal human intervention. Such technologies will enable more sustainable and autonomous exploration missions.

“The final milestone of this competition is a culmination of extremely hard work by bright, inventive minds who are helping us advance the technologies we need for a sustainable human presence on the Moon, and then on Mars,” said Monsi Roman, program manager for NASA’s Centennial Challenges, which is managed at Marshall Space Flight Center. “We celebrate their vision, dedication and innovation in developing concepts that will not only further NASA’s deep-space goals, but also provide viable housing solutions right here on Earth.”

The habitats were constructed in 10-hour increments in front of a panel of judges. Once printing was complete, the structures were subjected to several tests and evaluated for material mix, leakage, durability and strength.

Beginning in 2015, the multi-year, multi-phase competition challenged teams to demonstrate many different additive manufacturing technologies, from design to software modeling to physical construction. The unique challenge was competed in three phases: design, structural member and on-site habitat construction. The challenge structure allowed NASA to task the teams to address many facets of 3D construction, and to involve a broader range of teams with various expertise. More than 60 teams have competed throughout the competition, and NASA awarded over $2 million in prize money.

NASA’s Centennial Challenges program is part of the agency’s Space Technology Mission Directorate, and is managed at Marshall. Learn more about the 3D-Printed Habitat Challenge.

NASA Michoud Team Prepares Forward Join for Horizontal Assembly

NASA is charged to get American astronauts to the Moon by 2024. SLS and Orion are our backbone for deep space exploration including missions to the Gateway in lunar orbit. The agency will launch SLS and Orion from NASA’s Kennedy Space Center in Florida on their first integrated test flight around the Moon in 2020. Credits: NASA/Jude Guidry

Crews at NASA’s Michoud Assembly Facility moved the forward join, or forward part, of the massive core stage for NASA’s Space Launch System in preparation for its final assembly and integration to the liquid hydrogen tank. In a change from the previous core stage assembly plan, technicians and engineers will mate the forward join with the liquid hydrogen tank horizontally rather than vertically. This revised approach of mating the two critical components allows technicians and engineers to finalize the outfitting and testing of the engine section concurrently. Combined with the use of new production tools, the new assembly process keeps core stage production on target for completion later this year. (NASA/Steven Seipel)

January 29, 1971: Apollo Columbia Command Module Lands in Montgomery

By Brian Odom

On July 24, 1969, the Apollo 11 Columbia command module splashed down in the Pacific Ocean, ending the incredible journey of astronauts Neil Armstrong, Edwin “Buzz” Aldrin and Michael Collins. From the moment the powerful Saturn V launched from Kennedy Space Center on July 16 until recovery by the aircraft carrier Hornet crew, the world had watched with pronounced anticipation as the bold mission unfolded on television sets in homes, bars and storefronts across the globe.

In 1970 and 1971, the recovered Apollo 11 command module Columbia embarked on another journey — this one consisting of a 13-month tour of the 50 states and Washington. The tour brought the celebrated space hardware directly to the communities of the men and women who labored diligently to solve the lengthy list of difficult technical, logistical and political challenges faced throughout the decade of the Apollo program.

The Apollo 11 command module arrived in Montgomery, Alabama, on Jan. 29, 1971, just two days before the launching of the Apollo 14 lunar landing mission. Alabama Gov. George Wallace spoke at the opening ceremony, with Alabama State Finance Director Gen. Taylor Hardin presiding over the event. The 1970 Alabama Democratic gubernatorial primary was a closely contested affair, with Wallace narrowly defeating incumbent Albert Brewer in a runoff. While Brewer counted Marshall Space Flight Center Director Dr. Wernher von Braun among his close friends, Wallace was a long-time opponent of federal influence in the state — particularly related to the battle over civil rights and the process of desegregation. The celebration of such a profound national achievement seemed to override the deep wounds of past conflicts.

Over three days, approximately 89,000 visitors passed through the lunar exhibit — a number NASA reported to be among the best at any capital in the tour. Alabamians not only took pride in the great national accomplishment of completing President John Kennedy’s monumental goal of landing man on the moon by the end of the 1960s, but also in their state’s own vital contributions to the lunar landing. During the years of the Saturn program, the economy of North Alabama, in particular, transformed from one dominated by rural agriculture to a Sun Belt economy characterized by increasingly technical fields.

Of course, Montgomery was just one stop of the command module’s pilgrimage across the country. NASA’s final report following the tour proclaimed that everyone from “babes-in-arms to senior citizens” had “regularly queued up in lines several blocks long” and waited for several hours to see first-hand the historic space hardware. The turnout of more than 3.25 million spectators over 1970 and 1971 spoke to the high level of national pride in the success of the Apollo program.

Following the tour, the command module made its way back to Washington, where it was displayed in the Smithsonian Institution’s Arts and Industries Building before being installed as a permanent exhibit in 1976 in the halls of the newly opened National Air and Space Museum. In 2017, the command module took to the road again, embarking on a tour to Houston, St. Louis, Pittsburgh and Seattle before it returns home in 2020 to the Air and Space Museum as part of a new exhibit — “Destination Moon: The Apollo 11 Mission.”

From its original launch in July 1969 to its return to Washington, the Apollo command module Columbia continues to inspire new generations of Americans and serves as a testament to the monumental national fulfillment of an audacious presidential objective. Reflecting on its time in Alabama is a reminder of the great work accomplished during the Apollo program and envisages future celebrations of accomplishments just around the corner.

Odom is a Historian at NASA’s Marshall Space Flight Center.

Spectrabotics CEO Tim Haynie to Deliver Tech Talk on May 9

Spectrabotics CEO Tim Haynie will deliver Marshall Space Flight Center’s monthly Tech Talk on May 9. Haynie will speak about machine learning on multispectral imagery for object detection and analysis. The technology may be used by drones to help with environmental monitoring for pest and stressors to plant life. Spectrabotics was one of the 10 finalists in NASA’s iTech program in 2018. Marshall team members are invited to listen to Haynie’s discussion at 1 p.m. in Room 4078 of the National Space Sciences and Technology Center on Sparkman Drive. (NASA/Marshall)

Marshall Educator John Weis Shares NASA Messages with Illinois Students

NASA’s Marshall Space Flight Center educator John Weis, right, offers students from Manual Academy High School in Peoria, Illinois, a first-hand look at a Moon rock retrieved by the Apollo 15 mission. The Moon rock was on display at Caterpillar’s Edwards Demonstration & Learning Center in Edwards, Illinois, on May 3. Weis is among thousands of educators across the country being honored during Teacher Appreciation Week. For more information on Marshall’s Office of STEM Engagement, including materials available for educators, please visit here. (NASA/MSFC/Emmett Given)

Marshall Talks Space with Students on Mission Control: Human Spaceflight

Team members from NASA’s Marshall Space Flight Center answer questions from students during Mission Control: Human Spaceflight, an Alabama Public Television event hosted at the U.S. Space & Rocket Center on May 3. Four panelists discussed science, engineering and the history of human spaceflight in a live Q&A watched by approximately 200,000 students in fifth through eighth grades. The hour-long event was also streamed on Facebook Live and is available for viewing on Facebook. From left are Teresa Vanhooser, former Marshall deputy director; Brian Odom, Marshall’s historian; host Steve Johnson of WHNT TV; Stephanie Shelton, an International Space Station payload communicator at the Payload Operations Integration Center at Marshall; and John Blevins, deputy engineer of the Space Launch System program. (U.S. Space & Rocket Center)

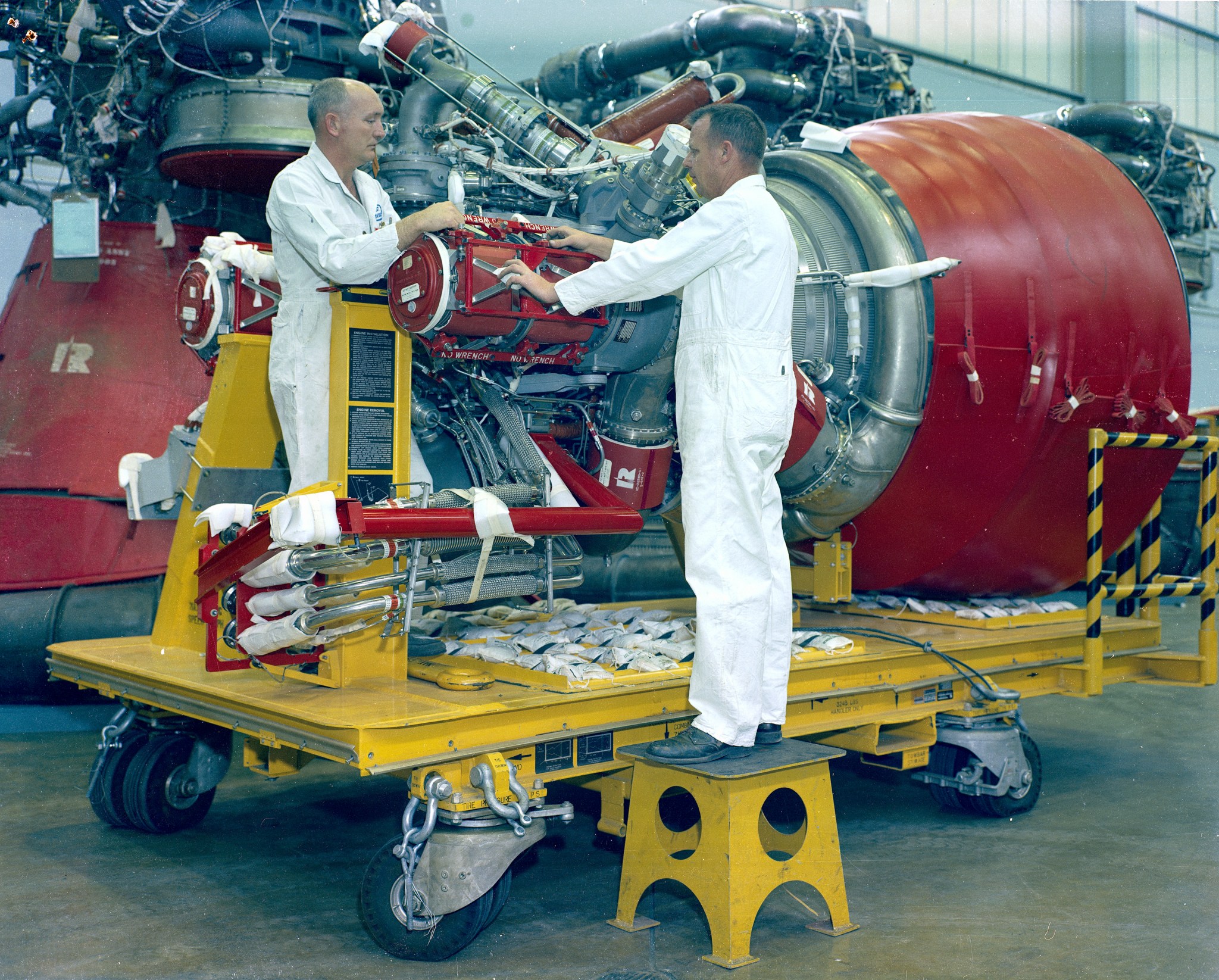

This Week in NASA History: Uprated J-2 Engine Arrives at Marshall – May 6, 1966

This week in 1966, NASA’s Marshall Space Flight Center announced it had received the first uprated J-2 engine from Rocketdyne. The J-2 was initially rated at 200,000 pounds of thrust, but a higher thrust was needed for the second and third stages of the Saturn V, beginning with AS-504, the Apollo 9 launch vehicle. A cluster of five J-2 engines was employed on the S-II, or second, stage and a single J-2 was utilized on the S-IVB, or third, stage of the Saturn V rocket. Here, a J-2 engine is being processed at Marshall, where the Saturn V rocket was designed. Now through December 2022, NASA will mark the 50th anniversary of the Apollo Program that landed a dozen astronauts on the Moon between July 1969 and December 1972, and the first U.S. crewed mission — Apollo 8 — that circumnavigated the Moon in December 1968. The NASA History Program is responsible for generating, disseminating and preserving NASA’s remarkable history and providing a comprehensive understanding of the institutional, cultural, social, political, economic, technological and scientific aspects of NASA’s activities in aeronautics and space. For more pictures like this one and to connect to NASA’s history, visit the Marshall History Program’s webpage. (NASA)