NASA’s Commercial Crew Program

2016 Year in Review

Boeing and SpaceX made numerous advances on their crew transportation systems set to carry astronauts to and from the International Space Station for NASA's Commercial Crew Program. Both companies began building the spacecraft that will fly the flight tests for the program before beginning crew rotation missions. Boeing is building the CST-100 Starliner to fly on a United Launch Alliance Atlas V rocket, and SpaceX is building its Crew Dragon spacecraft to launch atop the company’s Falcon 9 rocket.

The year marked a substantial transition from design of critical elements and systems in previous years to the manufacturing of the spacecraft and launch vehicles, substantial modifications to launch complexes in Florida and the first integrated simulations of the teams that will oversee the flights. Along the way, advances were overseen by NASA engineers and the astronauts who will fly the spacecraft into orbit for the flight tests.

Astronauts aboard the International Space Station received and installed the International Docking Adapter, or IDA. The Boeing-built adapter launched on a SpaceX Falcon 9 rocket and Dragon cargo spacecraft, and arrived at the station July 20. Expedition 48 Commander Jeff Williams and Flight Engineer Kate Rubins of NASA conducted the spacewalk to install the equipment. The two astronauts ventured outside the space station’s Quest airlock to install the first IDA onto Pressurized Mating Adapter-2, located on the forward end of the Harmony module on August 17.

Astronauts are working closely with Boeing and SpaceX as the companies mature their designs and conduct final testing and evaluation. The astronauts selected to train for Boeing and SpaceX’s flight tests--Bob Behnken, Eric Boe, Doug Hurley and Suni Williams--are learning about the two companies’ systems and participating in human-in-the-loop testing.

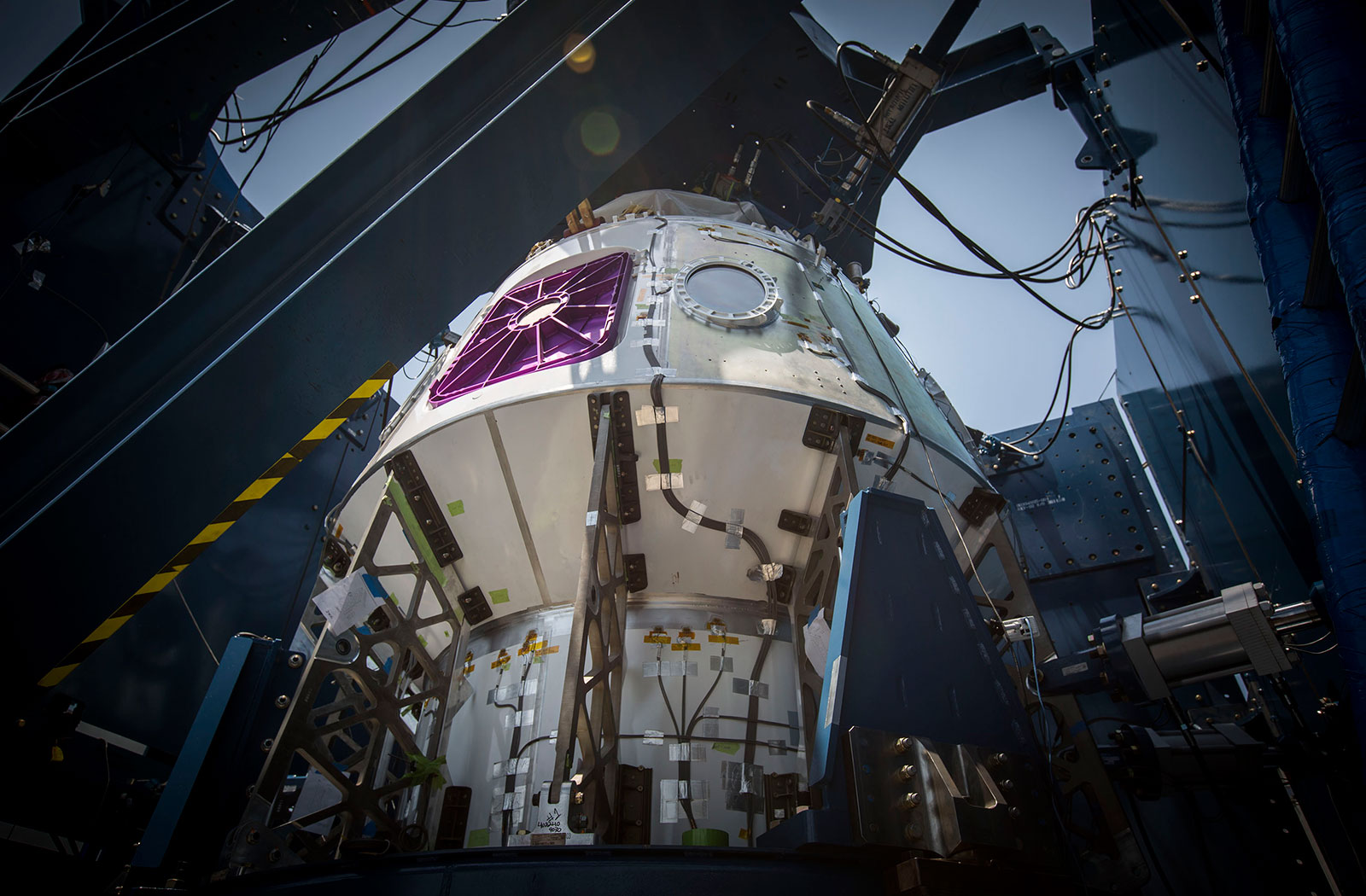

Boeing's Starliner structural test article, or STA, was completed at the company’s Commercial Crew and Cargo Processing Facility at NASA's Kennedy Space Center in Florida. Engineers and technicians also began major assembly work on Spacecraft 1, which will fly the pad abort test, currently slated for early 2018. The STA and Spacecraft 1 are critical elements in Boeing's plans to first prove the Starliner's design with extensive tests.

The second and third flightworthy Starliners – Spacecraft 2 and Spacecraft 3 – also entered manufacturing in 2016 and are in different phases of production.

SpaceX has five Crew Dragon spacecraft in different levels of assembly. The company built and successfully tested one module to prove its environmental and life support systems and another as a structural test article. The three spacecraft that will fly the flight tests and the first operational mission to the space station are in various stages of production in SpaceX’s manufacturing facilities in Hawthorne, California.

Before NASA certifies the spacecraft and rockets for their flight tests, each system will undergo extensive analyses, including exhaustive qualification tests and computer modeling. These highly realistic tests push the systems to their limits.

Engineers dropped a Starliner mock-up onto dirt and in a large pool, simulating normal and emergency landing scenarios, to gauge whether the system will work as planned. Hung from a gantry at NASA's Langley Research Center in Hampton, Virginia, the Starliner was released at different speeds and angles while cameras rolled to capture data.

There was also expansive wind tunnel testing, significant testing of the launch abort, reaction control and orbital maneuvering engines, as well as an acceptance test of one of the Centaur engines on the rocket that will lift the Starliner and its crew into orbit during the Crew Flight Test.

Boeing adjusted the design of the integrated Starliner/Atlas V system to ensure consistent airflow during launch and ascent. The design was modified to add an aeroskirt to the Starliner service module to smooth airflow around the top section of the rocket and spacecraft. The skirt will be jettisoned after the rocket leaves the thickest part of the atmosphere a few minutes after liftoff.

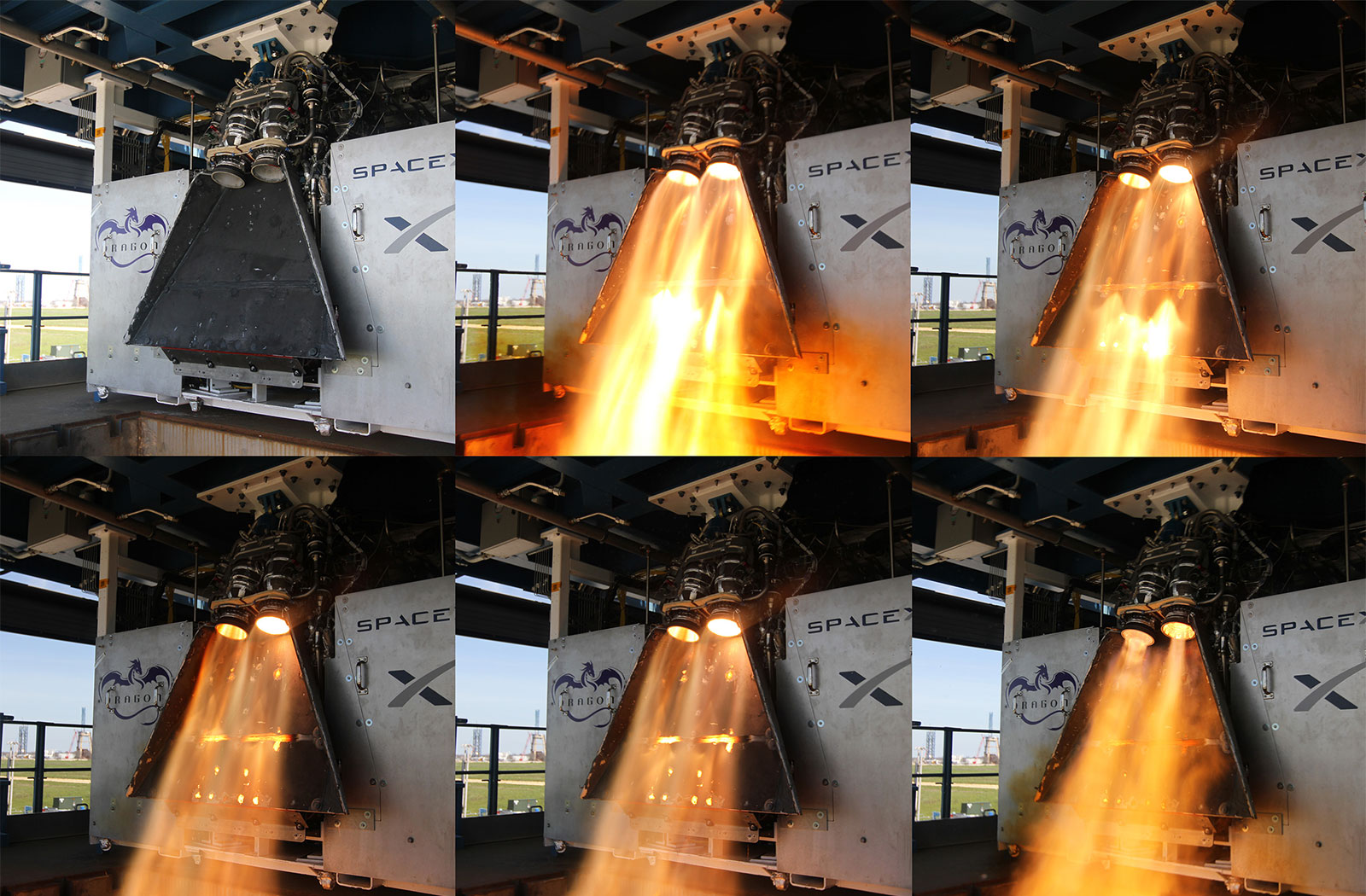

SpaceX performed five drop tests to evaluate the parachutes that must deploy to allow a returned Crew Dragon to land safely in the water. The SuperDraco engines that will be used on the first flight test were also hot-fired to qualify them for flight.

The company also ran a series of qualification tests on the spacesuits astronauts will wear during missions aboard Crew Dragon spacecraft. The evaluation included putting the suit in a vacuum chamber to see how it withstood conditions similar to those found in space outside a spacecraft.

A pair of launch pads at the spaceport on Florida's Atlantic Coast saw a renaissance in 2016 as Boeing and SpaceX added new capabilities and structures designed for the unique needs of astronauts and ground support staff.

At Space Launch Complex 41, the launch pad for the United Launch Alliance Atlas V, construction workers finished a new, 200-foot-tall Crew Access Tower in 2016. With an elevator and wide walkways, the tower was designed with astronauts in spacesuits in mind. The Crew Access Arm, which acts as a bridge from the tower to the CST-100 Starliner for the crew to board, was added in August. The work was done while launches from the pad continued with Atlas V rockets carrying other spacecraft into orbit.

SpaceX continued extensive modifications at Launch Complex 39A during 2016, which included pad structures being refurbished or rebuilt to serve Falcon 9 and Falcon Heavy rockets instead of the space shuttles that previously launched from it. Additionally, the Crew Access Arm has been built, and SpaceX expects to bolt it into place on the tower in 2017. The fixed service structure and its foundations were strengthened to handle higher-force hurricane winds and to provide a stronger base for the vertical integration crane planned for the complex in the future.