The Green Propellant Infusion Mission, or GPIM, project team has propelled itself through a successful Preliminary Design Review — a critical NASA milestone in which the payload design, vehicle integration and associated ground support plans are deemed technically and programmatically achievable in order to fulfill the mission objectives.

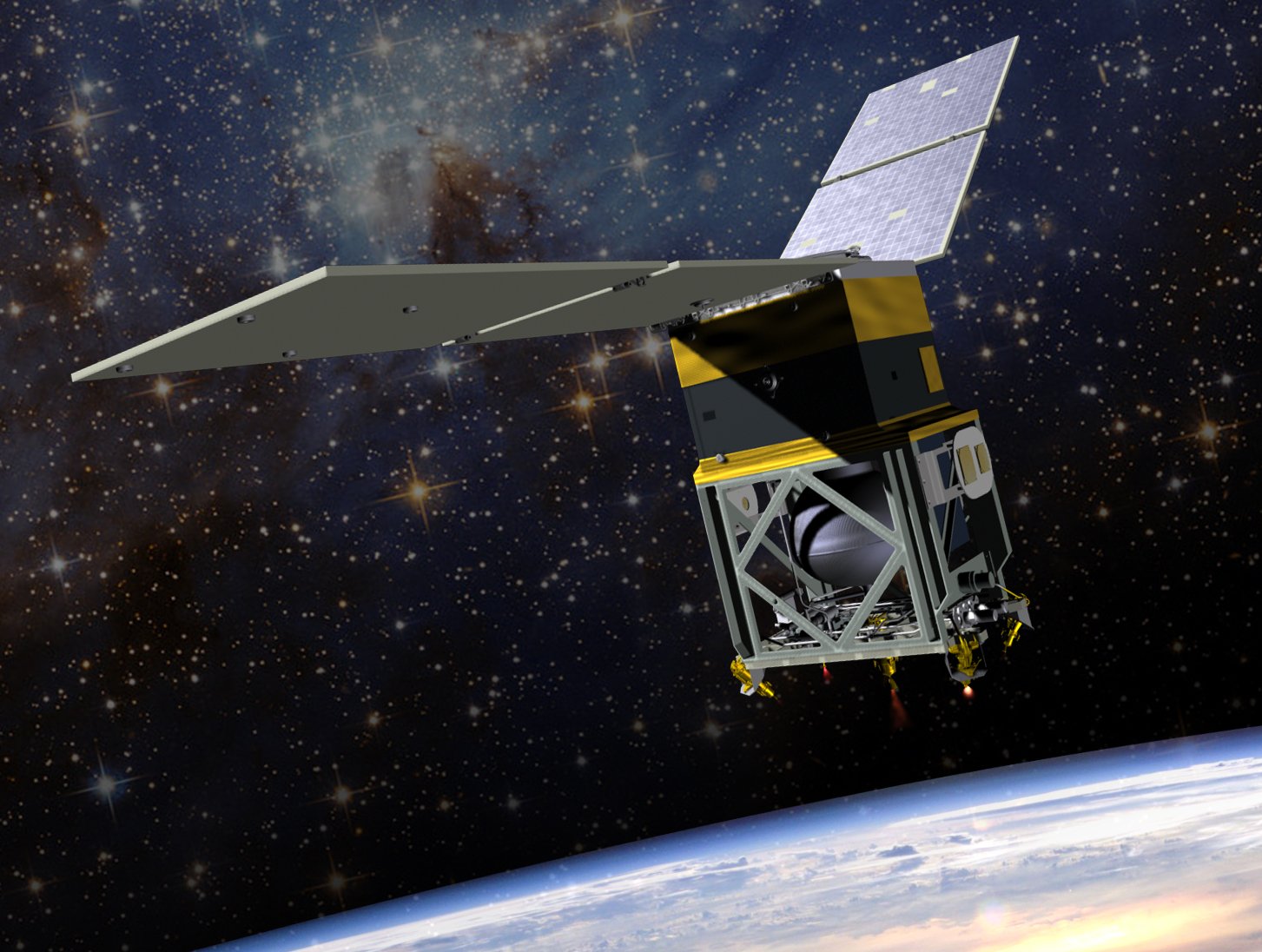

The GPIM team is developing and will fly the green propellant demonstrator as a subsystem on a Ball BCP-100 spacecraft bus designed for easy integration of “ride-share” payloads. It’s set to launch as a secondary payload on the Air Force STP-2 mission in late 2015.

The team is led by Ball Aerospace & Technologies Corp. of Boulder, Colo., and includes Aerojet Rocketdyne of Sacramento, Calif.; the U.S. Air Force Research Laboratory at Edward Air Force Base, Calif.; the Air Force Space and Missile Systems Center at Kirtland Air Force Base, N.M.; and two NASA field centers: NASA’s Glenn Research Center in Cleveland and NASA’s Kennedy Space Center, Fla.

The program has received some high-profile media attention recently. Why?

“Several reasons,” said Chris McLean, GPIM principal investigator at Ball Aerospace. “It’s green, or relatively non-toxic in comparison to conventional fuels such as hydrazine, and it has high performance. This mission also represents a rare opportunity to advance the state of the art in spacecraft propulsion technology.”

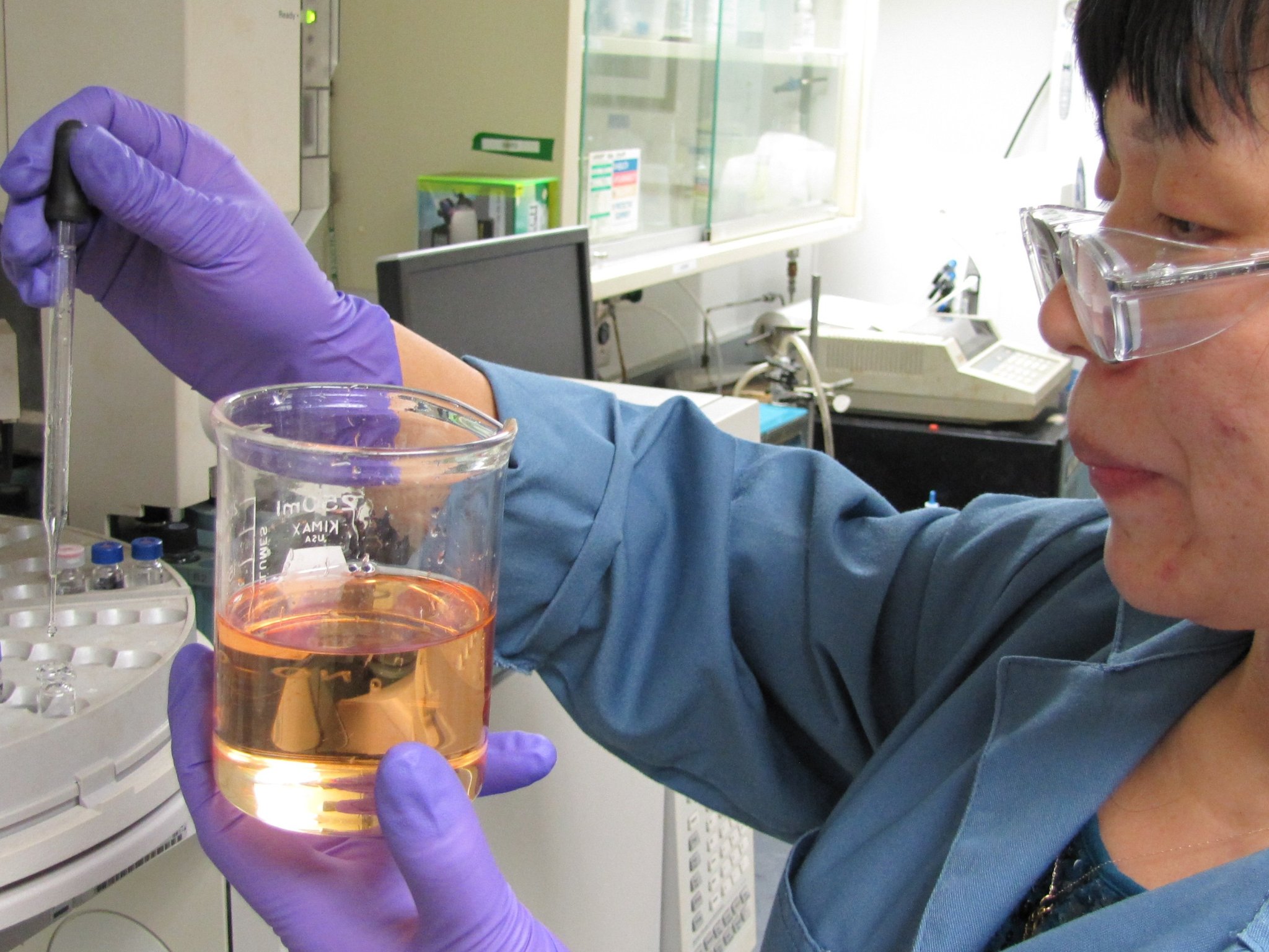

It’s the first time the nation will use a spacecraft to test green propellant technology. The mission propellant, a hydroxyl ammonium nitrate fuel/oxidizer blend known as AF-M315E, offers nearly 50 percent better performance when compared to traditional hydrazine fuel. It also reduces environmental impact during propellant loading, potentially increases payload capacity, enhances spacecraft maneuverability and makes longer missions possible.

The fuel’s safety rating and nearly non-existent vapor pressure translate to simpler spacecraft systems, simpler ground procedures before launch, reduced hazard-operations classification and safer propellant handling and loading for workers, who won’t need to don hazmat suits when working around the fuel. AF-M315E presents the potential for significant cost savings per launch.

The Preliminary Design Review, held July 23-24 at Ball, demonstrated that the project met all requirements with acceptable risk and within cost and schedule constraints, and established the basis for proceeding with detailed design. The team received “a lot of positive feedback” during the review, McLean said, and no critical issues were identified.

The GPIM project is a NASA Technology Demonstration Mission. Managed for the agency by NASA’s Marshall Space Flight Center in Huntsville, Ala., the TDM program is part of the Space Technology Mission Directorate in Washington, which is charged with innovating, developing, testing and flying hardware for use in NASA’s future missions.

“We’re excited by the GPIM team’s successful completion of this milestone review,” said John McDougal, manager of the Technology Demonstration Missions Program Office at the Marshall Center. “We’re confident the project is on track to deliver a high-performance, high-efficiency alternative to conventional chemical propulsion systems that will revolutionize how we safely and efficiently deliver new generations of exploration missions to space.”

Maturing Thruster Technologies

With the Preliminary Design Review behind them, the team continues work to complete the design. In coming months, they will mature both 1 Newton and 22 Newton thruster technologies from the current laboratory models through flight-qualified designs. Thrusters are an essential element of the Green Propellant Infusion Mission project, McLean said; they’ll process the green propellant and initiate the spacecraft’s orbit and altitude changes.

The GPIM team selected the 1N and 22N classes of thrusters, McLean said, “because they represent the largest market share for this technology — and therefore the most direct path for infusion.”