NASA Low Boom Flight Demonstrator Deputy Project Manager Cathy Bahm discusses the X-59 quiet supersonic research mission.

Cathy Bahm: The creation of a market for supersonic commercial aircraft requires eliminating the sonic boom as a barrier for over land flight.

NASA believes that changing that standard will open up the market for commercial supersonic transports. And that’ll be a game changer for transcontinental and international flight.

I can’t wait to be able to fly from the West Coast to the East Coast in half the time.

Deana Nunley (Host): Welcome back to Small Steps, Giant Leaps, a NASA APPEL Knowledge Services podcast where we tap into project experiences to share best practices, lessons learned and novel ideas.

I’m Deana Nunley.

From streamlined aircraft bodies and lightweight composite structures to computer software tools, every U.S. aircraft and air traffic control tower in operation today use some kind of NASA-developed technology.

Our podcast episodes in August are focusing on aviation and taking a closer look at NASA aeronautics research. Today we’re talking about quiet supersonic flight over land, and our conversation is with Cathy Bahm, the Deputy Project Manager for the Low Boom Flight Demonstrator Project at NASA’s Armstrong Flight Research Center.

Cathy, thanks so much for joining us on the podcast.

Bahm: Thank you so much for having me. I’m so excited to have this opportunity to talk about the Low-Boom Flight Demonstrator project.

Host: Could you give us an overview of the project?

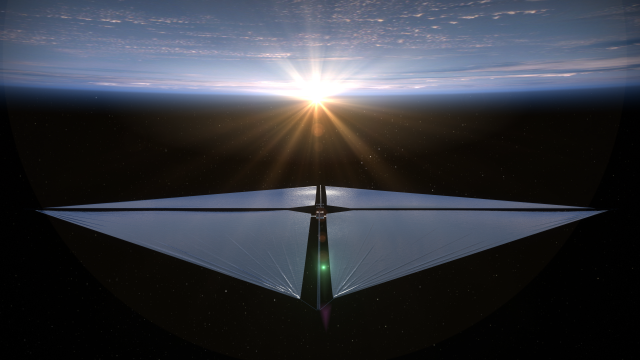

Bahm: The Low-Boom Flight Demonstrator project is responsible for the design, build, and test of the X-59 QueSST, which stands for Quiet SuperSonic Technology aircraft. The X-59 is a one-of-a-kind X-plane specifically designed to quiet the boom. The X-59 is designed to have a sonic thump of 75 PLdB, which is like a car door closing down the street from your house, or like distant thunder. To compare that to the Concorde it had a noise level over 100 PLdB, and it was more like nearby thunder, or being in the car when the door slammed.

Traditionally, we would test the X-plane and its technologies, but with X-59 we’ll do some of that, but it’s ultimately being developed to test people’s response to the low-noise sonic booms.

Host: So, what’s NASA doing to reduce the loudness of a sonic boom to a gentle thump?

Bahm: So, NASA and our partners have spent decades studying sonic booms. We’ve developed tools, performed ground tests, completed field studies and some flight tests like our Quiet Spike project, and our Shaped Sonic Boom Demonstrator project. The design of X-59 leverages all of that work. It’s designed to control the strength and the distribution of the shock waves coming off the bottom of the aircraft, so they don’t merge and generate the characteristic of an end wave that you would typically have for like the Concorde’s sonic boom. Through the design, we’re shaping the signature of the X-59 on the ground.

Some of the key features that allow us to do that is we have a very long nose. The nose is 30 feet, which is about a third of the length of the vehicle. And it’s used to shape the forward shock, and spread out the shock waves on the front part of the vehicle. And then, we have a T-tail that’s at the top of the vertical tail and that’s used to tailor the aft shock. And then, unlike most aircraft, we have our engine above the wing. And we also have our environmental control system intakes and exhausts above the wing. And that’s all to minimize the contribution of those items to the shock waves under the vehicle. So, those are some of the key design features that help shape a signature when the shock wave’s coming off the vehicle. And then, when it gets to the ground, we’ll have that sonic thump more than a sonic boom.

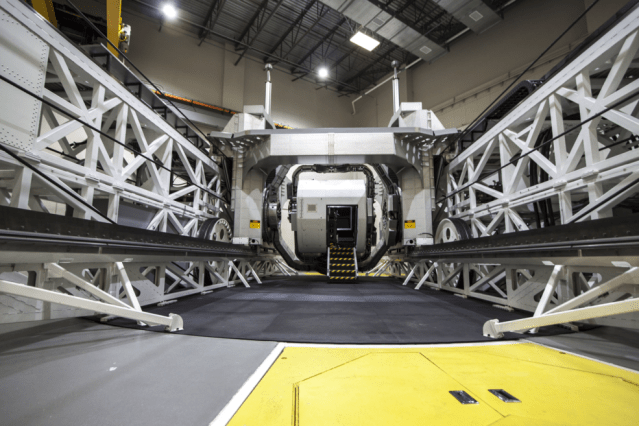

Host: How far along are you in the X-59 manufacturing process?

Bahm: We’re pretty far along at this point. It’s starting to look like an airplane. When we started it just had a few of the wing ribs. Now, it really looks like an airplane.

We’re almost ready to install the vertical tail and the nose. And then, it’ll start looking like all the photos and artist renderings that you see minus the actual paint scheme, at this point. Right now, we’re in the process of installing the subsystems and testing those subsystems.

Our next big milestone for manufacturing is to ship the aircraft to Lockheed Martin Fort Worth for our ground loads tests and fuel calibration test. And that’s expected to be later this year.

Host: And then, when do you start the initial flight tests?

Bahm: So, our current plan for the first flight is to happen summer of 2022.

Host: Wow, so not that far away.

Bahm: Yeah. It’s less than a year away, at this point.

Host: Can you talk to us about those flight tests? What’s going to happen when the tests actually occur?

Bahm: So, we’ll fly an initial 5 to 10 flights out of Palmdale as a functional test of the systems. And then, it’ll be transferred to NASA Armstrong where we’ll do the remainder of, what we call, envelope expansion. And that will show that the X-59 is safe and performs as planned across all of the performance envelope that we intend to fly in.

Then, we’ll transition to do the acoustic validation phase and that kind of will occur in spring of 2023. This is where NASA will fly the X-59 to prove that the quiet supersonic technology design is as planned and is ready for community testing. Then our project will turn the vehicle over to another project. And they will perform the first community response tests in the spring of 2024 with the aircraft based at Armstrong. And we’ll test the community in this general area. And then, there’ll be three to five additional community tests at locations across the United States. We’ll select representative communities with varying characteristics, such as like topography, climate, community types, such as urban, or rural, or suburban. And we’ll look for varying across those three to five community tests.

Host: Working inside this project, is it as cool as it sounds from the outside?

Bahm: Yeah, it’s totally cool. It really is. It’s a great mission, and it’s a really awesome team, both the NASA team and our contractor teams. It’s really been great project to work on.

For me, it’s like super cool because when I was an intern years ago, I got to be a part of sonic boom research. I spent a couple of semesters standing in the desert recording sonic booms from the SR-71 and some F-18s. And I absolutely loved it. So, now years later, after a bunch of other projects that I’ve been on doing very different stuff, I finally get to manage the project that’s building a piloted X-plane with a low-noise sonic boom. So, it’s really like a dream come true. And it’s amazing to get to work on a piloted X-plane. It’s just so exciting.

Host: Wow. That does sound so exciting. Could you talk about specific goals of the quiet supersonic mission? What are NASA’s specific goals?

Bahm: Yeah. So, right now, there are regulations that prevent commercial supersonic flight over land. The creation of a market for supersonic commercial aircraft requires eliminating the sonic boom as a barrier for over land flight. So, an international certification standard based on acceptable noise levels must be developed to replace those current over land restrictions. And it needs to be international because if you just do it for one country or another, then that limits you again because you can only fly supersonic over that specific area. So, if we can change the international standard that’s important. So, the overall goal of the mission is to provide data to the public response on low noise sonic booms to these regulators, and change the standard on the acceptable noise level.

So, right now, the FAA does not allow any commercial supersonic flights over land. And so, this would change, based on the public information, public data that we get on the response to these low noise. It’ll allow the regulators to be more specific and generate a noise level base. So, you would say aircraft under a noise level of 75 PLdB, for example, are permitted to fly over land. And so, that would allow aircraft developers to design aircraft that meet that standard.

And NASA believes that changing that standard will open up the market for commercial supersonic transports. And that’ll be a game changer for transcontinental and international flight. And, for me personally, I can’t wait to be able to fly from the West Coast to the East Coast in half the time, or get to vacation, and spend less time in the air, and more time on vacation.

Host: I think we all would agree with you there. What kind of a timetable are we looking at for these changes?

Bahm: So, the timetable would be from the time we get the community response data to being able to provide that to the standards organizations, the next meeting would be in 2028. And then, if they decide to make new rules, then that would be a couple of years for each of the international partners to put those standards in place. So, we’re looking at 2030-ish when you would see those actually changed.

Host: What are some of the major challenges you’ve faced from a project management standpoint?

Bahm: Yeah, we’ve definitely had our share of challenges. Just two months after we baselined the project, we had the longest government furlough ever. So, that really kicked off the project well.

Host: That was not in the project plan, right? [laughter]

Bahm: That was not in the project plan. That was not in our reserves. And then, for the last 16 months we’ve been managing in the middle of the COVID-19 pandemic. So, we keep wondering what’s next? We’ve put that in our plans. FY22 question mark, what’s going to happen there?

But seriously, we are building the aircraft during kind of an aviation and aerospace boom, which is great for the industry. But it has caused kind of an industry-wide personnel shortage. It’s been difficult to get and keep experienced workforce on the project. And it doesn’t just impact the team that we have, but it also impacts the supplier support because they have such a high demand. We only need a few parts, one-off parts, right? And so, they have significant demands from bigger activities. And so, that delayed a number of our subcontracts, and our parts are costing more, and taking longer to get delivered. And so, that’s been a real challenge that we’ve seen the repercussions over time with the schedule and the budget.

We also transitioned from the QueSST project, which was kind of the formulation and up through PDR for the project, preliminary design review. And then, we transitioned to the LBFD project after PDR. And that was a new contract, a new leadership team, mostly new leadership team, and a lot more rigor that was required when we transitioned to LBFD. So, that was a very difficult transition. And I don’t recommend it to future projects to do anything like that.

Host: And speaking of recommendations to other projects, are there lessons learned in addition to that that you’d want to share with other NASA projects?

Bahm: Yeah. So LBFD, we were formulated as a no host center project. Instead, it was designated as a system project office, and we reported programmatically to the program office. So, it was done to ensure the balanced approach, and taking full advantage of all of the strengths across the different centers. So, this was great because we could take advantage of the best person for the job, and the best processes across the centers. We weren’t tied to any specific process, or practices from a host center, as you traditionally would. If you had a host center, you would kind of lean towards using, or be expected to use the host center’s process.

So, we got to design our processes and do what was right for LBFD specifically. So, it also helped that the project manager, our PP&C lead, and myself had a lot of varied experiences. Our project manager came from outside NASA, had spent some time working for NAVAIR. And the PP&C lead and I have moved around NASA centers, and worked on various projects. And so, we could leverage those experiences, and the best practices we were aware of across the centers, and various projects when we developed our processes.

So, a really good example of that was that our PP&C lead was aware of a process that Goddard used for their liens, threats and encumbrances. So, we tailored that process, and used that for our team and our project. And that’s well outside what we would normally do if you were a host center, especially in the aeronautics side of the house. So, we’re leveraging something from one of the space centers, which was really great for us. So, this approach of designing the processes specifically for our project has really served us very well.

And another point kind of tied to the transition from QueSST to LBFD, we spent a lot of time as a leadership team developing our values and our operating principles. We also spent time laying out our roles and responsibilities, and we got buy-in from our leadership team on these processes I just mentioned. And that took time, and it was a very thoughtful process we used to make sure that it wasn’t us telling them that these are our values and our operating principles, but that we all, as a team, kind of generated those together.

And, for us, I think that’s made the difference because we helped our transition, and kind of bonded us as a team, as a leadership team. And it’s been really key in our management approach. We revisit those values and operating principles and our processes regularly to make sure that we are A, operating by what we say we’re going to do, we are actually doing. And then also the processes, they’re a living process. So, if as we’re using them, we find out that something’s not working, we can modify it, and make it better to work better for our project. So, those are some things that has really been useful for our project that I’d kind of recommend for future projects.

Host: Those are really helpful. Thank you for sharing those. I want to ask you about the technical part of this project. If you had to identify maybe one or two top technical challenges, the ones that are just really, really tough to figure out, what comes to mind?

Bahm: Yeah, that’s really an interesting question. So, I think most of the challenges for our project are less technical. For example, we’re really focused on the sonic boom, low-noise sonic booms, and generating that quiet thump. And so, that’s really our main focus. And so, we’ve designed the airplane, and we figured that out. So, most of what our challenges are now, are really building that aircraft, putting all of the subsystems and subsystem integration, fitting all of those subsystems into this package. You design the outer mold line of the vehicle so you get this quiet thump. But, now, you’ve got to fit all your subsystems into that shape.

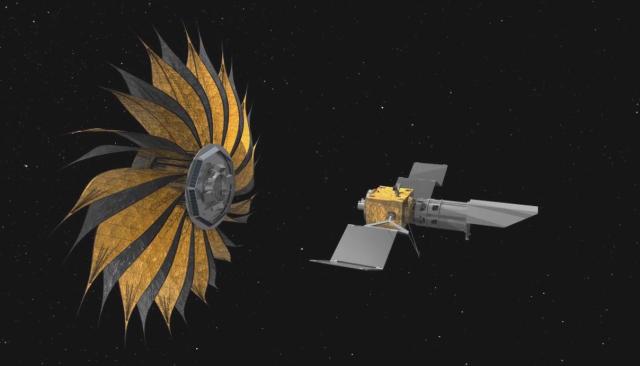

So, one example is we don’t have a traditional cockpit where the pilot can see out the front of the vehicle. We talked about the long nose. And so, NASA Langley team has worked on the external vision system, which will be used to give the pilot the view out, like he’s looking out the forward of the cockpit. But it’s done by having a camera on the nose, and also a forward vision system that kind of comes out of the bottom of the aircraft as you get to lower altitudes. And then, those recordings are displayed on a ultra-high def monitor in the cockpit for the pilot. So, that’s one challenge because of the outer mold line, and the design of the vehicle for this low-noise sonic boom.

Host: Cathy, we’ve focused our conversation on quiet supersonic technology. In a more general sense, how do you view the future of aviation?

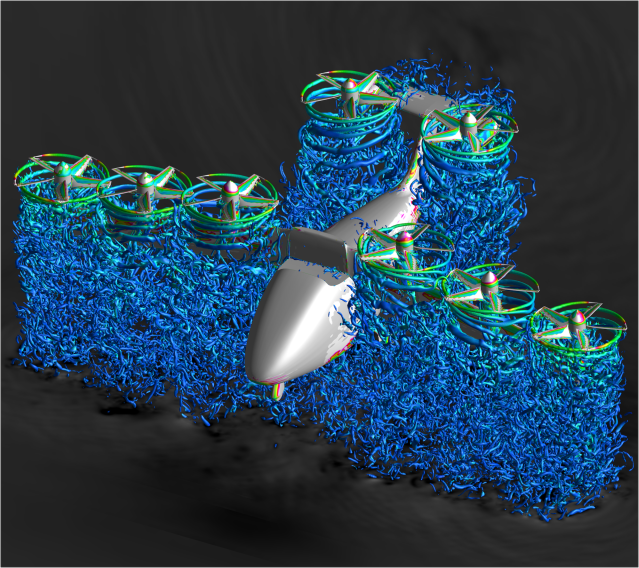

Bahm: I really think it’s an exciting time in aviation. There’s so many really exciting projects, amazing projects going on inside and outside of NASA. I mean, inside NASA, just as an example, we’ve got projects like X-57, Advanced Air Mobility. And they’re really cool activities, and they’re pushing the knowledge base, and the forward edge of these areas.

And it’s really interesting to watch all the innovation that’s going on right now, again, inside and outside of NASA. And it’s really exciting to see what the future holds for the aviation community.

Host: Many thanks to Cathy for joining us on the podcast. You’ll find her bio along with links to related resources and a transcript of today’s show at APPEL.NASA.gov/podcast.

If you’d like to hear more about NASA aeronautics research and what’s happening across the agency, check out other NASA podcasts at nasa.gov/podcasts.

As always, thanks for listening to Small Steps, Giant Leaps.