If you’re fascinated by the idea of humans traveling through space and curious about how that all works, you’ve come to the right place.

“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center from Houston, Texas, home for NASA’s astronauts and Mission Control Center. Listen to the brightest minds of America’s space agency – astronauts, engineers, scientists and program leaders – discuss exciting topics in engineering, science and technology, sharing their personal stories and expertise on every aspect of human spaceflight. Learn more about how the work being done will help send humans forward to the Moon and on to Mars in the Artemis program.

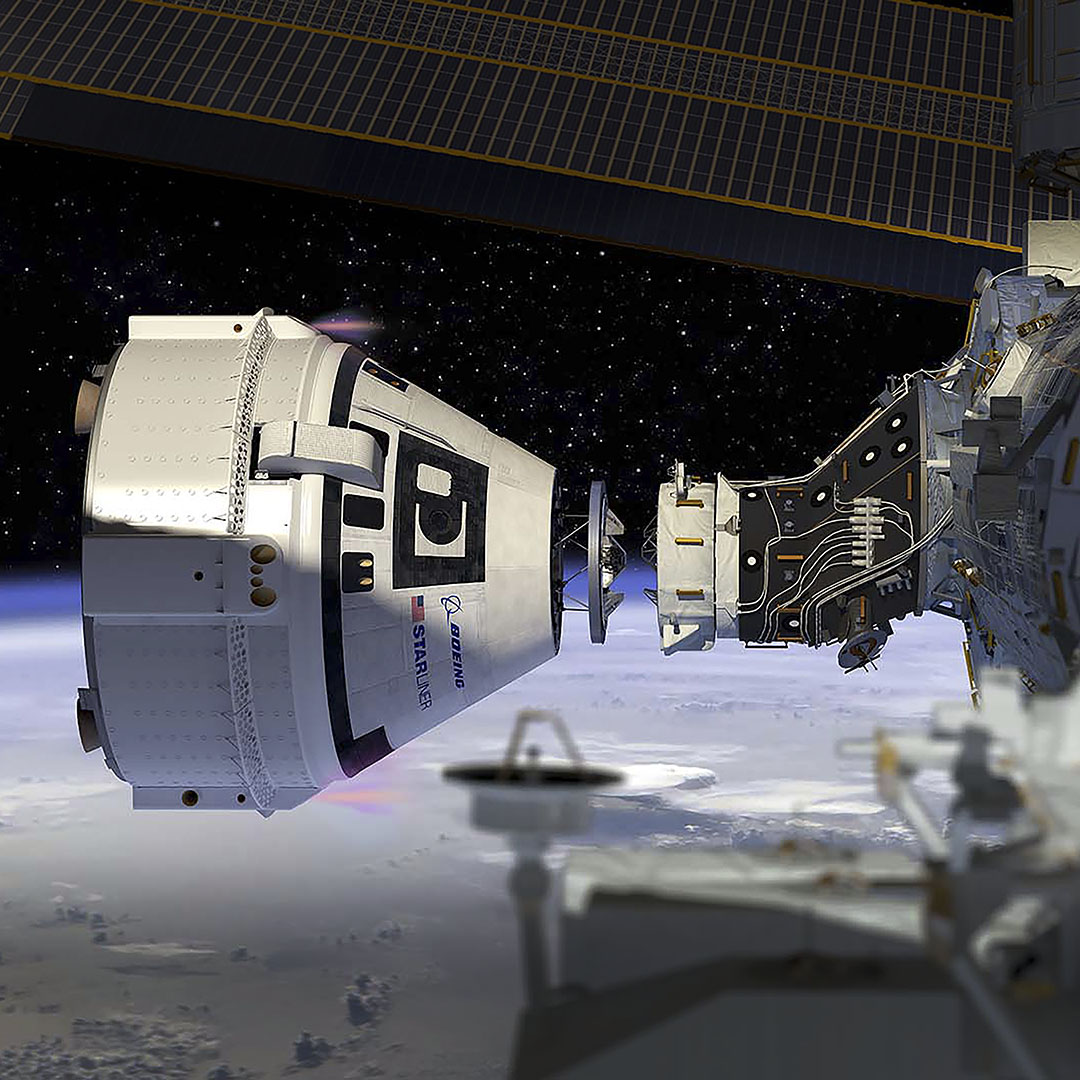

On Episode 108, Boeing engineers Tony Castilleja and Celena Dopart talk about the Boeing Starliner spacecraft and the testing and training happening to get that commercial crew vehicle ready for its first test flights. This podcast was recorded on November 1, 2018.

Transcript

Dan Huot (Host): Houston, we have a podcast. Welcome to the official podcast of the NASA Johnson Space Center. Episode 108, “The Boeing Starliner.” I’m Dan Huot and I’ll be your host today. On this podcast, we bring in the experts, NASA scientists, engineers, astronauts and leaders to tell you all the coolest parts about NASA. We’re close to launching astronauts from American soil with two different vehicles developed by two different companies. Boeing and SpaceX. It’s all part of the commercial crew program designed to enable the capability of launching people into space by private businesses. Today we’re going to highlight one of those vehicles; the Boeing Starliner. In the studio, we brought in Tony Castilleja and Celena Dopart. Tony and Celena are engineers with Boeing responsible for getting the spacecraft and the crew ready for these first missions. We talk about the vehicle itself, all of testing and all the training happening and what we’re going to be looking forward to in the very near future. So with no further delay, let’s go light speed and jump right ahead to our talk with Tony and Celena. Enjoy.

[Music]

Host: All right. I have Tony and Celena from Boeing with me today. Thank you guys so much for taking a little bit of your day to join me today. This is an exciting time. We got a new spacecraft coming, right?

Tony Castilleja: Oh, absolutely. It’s the best time to work in aerospace. We’re happy to be here. We’re training our astronauts today. Excited to be here today.

Celena Dopart: Very excited to make time for this.

Host: All right. So we’re here to talk about the Starliner. The CST100 Starliner. So first off, paint me a word picture. What does this thing look like? If you needed to describe this to somebody like, this is what you’re going to see, how would you do that?

Tony Castilleja: We’re building a spaceship. We’re building a spaceship today for the next generation of human spaceflight. Since the end of the space shuttle, NASA has contracted with Boeing to build the Boeing Starliner. It’s a capsule design that will launch up to five astronauts in its initial configurations to the International Space Station and all though it looks like a capsule that most Americans and most people around the world have looked at for generations, it’s a next generation spacecraft for a next generation mission.

Celena Dopart: And some of the differences between for example, our vehicle and Apollo say, it’s a little bit bigger. We’ve got a little bit more room. If you look at it and if you’ve seen, Orion, if you’ve seen Apollo, you kind of get the idea of what a capsule looks like. Our vehicle is similar but it’s got some unique differences. So, if we go in the interior of our vehicle, it’s more spacious. It’s certainly not, let’s say glamping. It’s more camping. There’s —

Host: Still tight space. Still spaceflight, it’s still tight quarters but —

Celena Dopart: Still tight quarters for sure. And when we get up to four crew members and it, it’s definitely shared space. But there’s enough room for them to do all the activities that they have to do and we’ve got all the support that’s needed on the interior to help them get station.

Host: So something I’ve heard several times and we’ve heard this with the Orion spacecraft and I’m sure you hear you guys here this with the Starliner is it’s that capsule shape. It’s that really iconic kind of triangular shape. Why do somebody’s spacecraft look like that?

Tony Castilleja: It’s physics. It goes back to the aerodynamics and the fundamentals of aerodynamics to provide the most efficient design. The best return L over D or lift over drag as you come back to the atmosphere. In this case, for our spacecraft for a land landing will be one of the first human rated formidable space vehicles to be able to do that. And so when we looked at the math and science and the physics of flight, that capsule design created the most economical, the safest, and the most reusable capability for our engineers to get ready for that flight.

Celena Dopart: And you look at the design of spacecraft in the past, there’s really two kinds. There’s space planes and then there’s space capsules. And so it was always going to be one of those two. If it ain’t broke don’t fix it. Just make it better and that’s what we’ve done with the capsule design we have.

Host: So let’s get into the better. What some of the, I mean, technology’s, so far since Apollo and everything. What are some of the cool new gadgets? What are some of the nice things if they’re glamping? You know, there’s not like a 60″ TV in there. But you know, what are some of the nicer things that the astronauts are going to have access to on these new missions?

Celena Dopart: So one of the biggest differences is pretty striking when you first go into our vehicle if you’re familiar with the space shuttle or Apollo. There’s a lot less inside in terms of switches and buttons and controls. I know there are shuttle cockpit mockups on-site so if any of our listeners have ever seen them on site, there are switches and buttons on every surface within reach of the commander and the pilot.

Host: Which like 12-year-old me inside of those would have been so — like there’s buttons everywhere buttons, buttons, buttons and switches. Like they’re so satisfying.

Celena Dopart: I know. It is fun to play with. It’s fun to play with. It’s a lot harder to control when there’s that many things to interact with. So, with the technology that’s come a really long way we’ve been able to simplify that a lot. So, I don’t know the numbers exactly but we have greatly reduced the number of buttons and switches that a crew has to interact with. We still have displays that give a lot of information. All the information necessary for a crewmember to make informed decisions and know what’s going on in their mission. But, there’s a lot less for them to have to do and have to do in an emergency or contingency situation. So we really streamlined operations and that’s one of the big differences.

Tony Castilleja: And as you look and you walk inside to our Boeing mockup trainer which is actually here at Johnson space Center, if you ever come by Building 9, you’ll see our Boeing trainer there. You walk in and it’s a much cleaner design if you will and it allows for more cargo capability as well as the crew capability to space station. And that miniaturization of technology that we’ve experienced since last time. You know we built the space capsule. But also we’ve integrated the capability in our new spacesuit to be able to start interacting with touchscreens and so we’ll have tablets that our astronauts can use for electronic flight logs on their mission. And so you’re starting to see that capability start to continue to make progress in these brand-new space vehicles. And so we want to make sure it’s right in and it’s safe for our astronauts in terms of tactile feedback in terms of the switches that we have in the vehicle which are optimized to go from autonomy to human driving if you will. And then back to autonomy. But then give the ability to continue to bring that innovation to the forefront.

Host: So you mentioned cargo. Let’s just kind of get into this stuff real quick. So how much stuff is this capsule going to be bringing? I mean including the people and the cargo because it sounds like there’s going to be room for both.

Celena Dopart: Yep. Absolutely. So all of this is defined by the NASA requirements that they give us. So SpaceX is designing to the same requirements that we are and so if you’re interested in the specifics, you can look at the 1130 requirements which are just available online. But our volumetric, what we have to carry in terms of cargo for NASA, is defined by that. I don’t know the number of the top of my head. But we also have to have the capability to carry zero to four crew members. So going back to what Tony was saying about autonomous versus not autonomous, we have to have the capability to fly zero people on our capsule and our first test flight is un-crewed so we really have to demonstrate that. But then we also have to be able to carry four crew members. So that’s going to be sort of the nominal mission once we get operational. We plan to carry four crew members and a full complement of cargo. So that’s where I go back to, it’s kind of camping. There is not a ton of space for hanging out and having fun. We don’t have the 60″ TV screen. But, there are windows in the vehicle and while we’re waiting to get to station, there’s plenty of things that they’ll be doing to take up their time.

Host: So what else is kind of inside the capsules? I’m assuming there’s some seats. There’s some buttons, not as many buttons as there used to be but there’s some buttons, some screens. What are some of kind of the other accoutrements, the other facilities for the crew members inside?

Tony Castilleja: Yes. So as you walk in the spacecraft you’ll see the ability for us to land in water in case of an anomalous scenario. But we’re baseline land so you’ll see the life raft in there as you come in. You’ll see a row of three seats on the top row with the furthest most seat as you walk into the spacecraft as if you were on the launch pad being the main commander and pilot of the vehicle. And as you look over to the right, you’ll see two seats on the lower row if you will, kind of in between seat one and two and then in between seat two and seat three on that top row. So you get kind of this you know, almost like a dice view from the top in terms of the five crew.

Host: Kind of staggered.

Tony Castilleja: Kind of staggered. And it goes back to CG. It goes back to basic you know, aerospace; basic physics.

Host: CG?

Tony Castilleja: Center of gravity. Center of mass. So to all those up and comers, it goes back to the basic aerospace and physics. And so —

Celena Dopart: Let me jump in for second. You said five crew members and we just talked about four. So we do have a fifth seat which we don’t plan to utilize for our nominal NASA missions. That fifth seat will be swapped out to be able to carry a little more cargo with a cargo pallet. But Tony is absolutely right. We could if we ever have the desire or another customer, take five crew members at a time.

Tony Castilleja: Exactly. So as you walk in you’ll see this white walls if you will, and the cargo on the left and right of you on each side. And when you think about where we put the switches and dials, it’s all about sitting in the pilot seat and imagining yourself — the amount of time you need to go reach a dial. Pretend that you are in your car, your Lexis, your Audi and you’ve got to move this seat in order to reach a certain button or dial. We did that with the seat and the reach and visibility of where the switches are. So the most important ones, caution and warning panels, things of that sort are very close to where your line of sight is. And then something like the temperature of your cabin is off to the left. And so where we put the switches and where we put the dials are really focused on the crew member for those safety scenarios in case of the autonomy takeover of the human. But again, less number of switches. The console’s in front of seat one and seat two on that top row. Seat three, four, and five, you have a lot more if you say looking around room if you will in our spacecraft.

Host: It’s — just real quick — it’s kind of crazy. You don’t always think about the level of detail that goes into design for these kind of things. But even something as simple as that like, which makes perfect sense when you hear it, yeah. The switches, the indicators that there’s an emergency should be really close to right out front and the less important stuff off to the side. I almost feel like has that level of detail gone into everything when you’re designing this kind of stuff?

Celena Dopart: Yeah, so especially for what Tony is talking about right now with the displays on the console and where things are laid out. It all comes down to good systems integration and human factors engineering. So I’m giving my plug for that because I’m a human factors engineer. But it really is — besides designing the systems and really strong, solid, robust systems, you need to make sure that they are designed for the end-user and our end-user is an astronaut. And we need to take into account all the other crew accommodations that go into the equation. The suits and the restraints that might prevent them from reaching something while they’re strapped in a high G phase of flight or when they’re on orbit. How do we have the accommodations to set up and let them have a little extra room to move around? So, there are some really creative engineering solutions we’ve come up with on our program. So our seats are sort of reconfigurable for the different sizes of crew members. We have to be able to take a whole range of anthropometric dimensions of crew members. So anywhere from 5th percentile female to 95th percentile male, everything needs to accommodate all of that range of crew members. So it’s a really challenging problem. But I wish this were visual so we could show you how we’ve done some of these things. But, it’s a really cool problem to be a part of the solution.

Tony Castilleja: Yeah. And for me as an engineer having built these trainers from the beginning, I mean, it’s almost like looking at a blank canvas and putting the right switches in the right places and having discussion with every single engineer, every single subsystem, every single expert, avionics, environmental control system, abort systems and scenarios, trajectory folks and being able to optimize all of that into this final painting that is the interior of our spacecraft.

Celena Dopart: Yeah —

Tony Castilleja: And that’s where we get to geek out.

Celena Dopart: And I will say it wasn’t easy and I’m sure every subsystem is annoyed that this one switch didn’t make it onto the final console. And so it really is a true systems approach where you have to get feedback and put buy-in from every single team who’s a part of it to ultimately come up with this final design that’s there.

Tony Castilleja: And I’ll tell you. If we’ve done it right which our team has validated every single as we go to, get ready to get on the launch pad, you’re only going to stare at that beautiful painting of a canvas. You’re there just for the ride.

Celena Dopart: Yeah. Hopefully you won’t really have to touch much. You’ll interact with the displays but it should be as smooth, pretty boring ride if we’ve done our job correctly.

Host: I feel like no right into space would ever be boring. But I appreciate that. Yeah. So if everything goes right, like you just kind of, you’re sitting back for the ride. If the spacecraft —

Celena Dopart: You’re making sure.

Host: — can fly with zero people like, the experience would be the same with four people.

Celena Dopart: Exactly. Exactly. You, the, when the crewmembers are on board, they’re primarily to respond to an anomalous situation. So for our nominal missions, which we hope every single one is a nominal mission and we expect them to be, the crewmembers will have to do a few things. But for the most part, everything can be done by ground that they have to do nominally. And everything else that the crew needs to do on a crewed flight is to support the crew. So, for example hygiene. There are certain things that the crewmember has to do on board to deal with hygiene situations, to food and water, the seatbelts, that sort of stuff. The crew has to interact with and so we need to make sure the crew can do it. But the ground can’t do it because the ground doesn’t need to do it. So when the crew is on board, there are certain things that have to happen that don’t have to happen on an un-crewed mission but we’ve made sure to design all those things so that the crew can do it themselves.

Host: So you talked about — you know it’s ultimately designed for that in the user, an astronaut basically. How much are they involved in the process because we’ve announced the first crewmembers who are going to be flying on here. There’s some NASA astronauts. There’s also a Boeing astronaut who used to be a NASA astronaut, commanded the last shuttle mission, Chris Ferguson. How much are they kind of in the mix and also being a voice? So you’ve got all those subsystems you know, arguing for what’s the most important thing. How important is the astronaut voice in all of this?

Tony Castilleja: Their experience when we hired former astronaut, NASA astronaut, Chris Ferguson over to Boeing has been tremendous. Not only in the design of the vehicle but to Celena and I as engineers and as individuals getting to build this spaceship. They were a part of every single meeting, giving their experience of riding on the space shuttle and other members of the astronaut corps to the NASA commercial crew cadre earlier in the program that gave us feedback along the way. At the end of the day our customers are NASA astronaut and getting their opinions and insight were instrumental and for us as engineers to get to work with folks who have flown on a variety of space vehicles has been truly the best part of this job.

Celena Dopart: And being right down the street from Johnson Space Center at the Boeing building that’s here in Houston has made it really easy to collaborate with the astronauts. So the original commercial crew cadre, the four of them who were announced a few years ago, like Tony said, they’ve been integral in pretty much every design meeting, decision, evaluation that we’ve done. And now that they’ve been assigned to specific crew members, to specific missions and we’ve gotten the additional crew members, those five who have been announced for our CFT and PCM1 missions, I see them on a weekly basis. We’re doing verification testing that they’re a part of. Our design is 99% done but there are still a few tweaks that are being done and the crew is a huge part of that. So, of course the NASA stack holders, the NASA engineers and SMEs, subject matter experts, but it’s really the end-user, the astronaut. We want to make sure that we meet all the requirements but also build a space craft that they want to fly on and feel comfortable flying on.

Host: Well now we’re kind of at the fun part though right? Like, it’s all being built but they’re also training. So how involved are you guys with the training?

Celena Dopart: Training has started already. They are training. I mentioned verification testing. That is partially doubling as some of their training. They’re getting really familiar with the systems both off-console systems and the Boeing mockup trainer in Building 9 and the on-console systems in our Boeing engineering simulator and Boeing mission simulator, both at Boeing in building five here at JSC on-site. So, Boeing is kind of interesting, the way we’re doing mission operations including training. We are contracting NASA to do some of our mission operations for us. There is just a wealth of experience that they have here. So, NASA FOD is helping out with our training and our mission operations. So that training has started. They’re using the Boeing mockup trainer over in Building 9 to do that training.

Tony Castilleja: Yeah and when you look at the overall time frames for overall training, these vehicles, the Boeing Starliner with its simplified approach, with its more autonomy, we’re going through every scenario in these training systems. But overall, the big focus is space station. So the last time you can train on our Starliner because of the simplicity of systems and the amount of innovation we’ve put in and the autonomy that allows for more focus on that space station training and really expands the aperture of the amount of science that we’re doing on space station and that’s what it’s all about beginning with our astronauts. And of course, ending with the great innovations and insights we’re learning from living and working in space.

Host: So what are some of kind of like the trainers that they’re getting their hands on? Because I remember like back during shuttle, we had one that would go up and it was motion based and you could fly. It was almost like a video game. It was the greatest thing in the world and I’m still so sad that we don’t have it any more. But like what are some of different trainers that they’re working on? What different functions do they serve?

Tony Castilleja: A day in the life of Boeing training starts at the Boeing mockup trainer, getting familiarized with the overall volumetric and human in the loop systems that you’ll be in. So as we described earlier, walking the space craft. Where is every switch? Where is every dial? What are all the switches behind you in the full scale trainer? You basically put yourself in a mindset of you’re on the launch pad at space launch complex 41 on the Atlas 5 rocket. You’re walking the space craft. What does it look like? We also go through a land landing scenario and even an off-nominal land landing scenario where you’re on the ground after a land landing and how do you get out through the top of the vehicle in a secondary approach if you will; an off-nominal approach for a land landing. So that gives you an overall physical environment understanding of the vehicle and the team has been tremendous in training both on the NASA side and the Boeing side to get that physical familiarization. And then we have our other trainer of the software perspective.

Celena Dopart: Yeah, so the Boeing mockup trainer is our physical geometric, volumetric, show where everything is. We have a couple simulations where they actually learn to fly the vehicle and interact with the subsystem via the displays. So we’ve got the Boeing engineering simulator which is a quarter cockpit. So it’s got the commander and pilot and the mission specialist one seats and all of the console displays and switches. That’s at the Boeing building here in Houston. We have a very similar but slightly higher fidelity mission mockup environment in building 5 here at JSC. It’s called the Boeing mission simulator and that’s very similar to the best in that you interact with the displays. You fly simulations but you’re more enclosed in the capsule so it feels a little more like an actual mission would.

Host: But they’re getting like simulated pictures and stuff like that.

Celena Dopart: Yep so actually both of those run off of real flight software and are driven by engineering models that are really high fidelity to model and simulate the ECLS for example; Environmental Control and Life Support. As well as the EPS; the Electrical Power System. All of those systems are simulated and then it interacts with the flight software to give a very realistic mission for the crew members to train.

Tony Castilleja: And you can’t beat the view out the window; a 4K rendition back on Earth as you go and do your mission and put approach space station.

Celena Dopart: Yeah.

Host: Well that — yeah.

Celena Dopart: And there are a few more. We’ve got tons of trainers. Of course that’s a focus for any space mission right? The astronauts need to find ways to train here on the ground and so we also have a few part test trainers which are another way for them to interact with the simulation and the flight software. But they’re more virtual cockpit so it’s touchscreen. It’s not quite as tactile as the BES and BMS but they still get practice with the flight software. And then of course there’s the training for the ground team. So, we’re going to have mission control here at JSC and we’re doing full up simulations with people in the BMT, the Boeing Mockup Trainer, the physical one doing tasks there. People in the BMS, flying an actual vehicle with people on the ground over the loops talking through a real mission scenario. So we kind of — unfortunately we don’t have one big iron horse where we can do everything all at once. But we piece it together here on site and can simulate every single part of a real mission.

Tony Castilleja: And that’s what training is such that when you’re on the launch pad nothing is a surprise in terms of how we’ve trained our astronauts to get ready to fly.

Host: And so you’re covering every imaginable scenario.

Tony Castilleja: Everything. And the really great thing about being in Houston here at Johnson Space Center is that the Boeing Mockup Trainer, the Boeing Engineering Simulator, the Boeing Motion Simulator over in building five are all co-located. So where an astronaut can go from Boeing Starliner training over to their mission and expedition training, they’re on the space station mockups as well.

Celena Dopart: And I will say, we don’t know what we don’t know. So I’m sure there are scenarios that they will encounter that we haven’t trained. But the whole point of training is to train a representative set of scenarios that gives them the knowledge and the training to be able to respond to scenarios that we may not have covered in specific detail here as how you respond exactly. But they should have the subsystem knowledge, the full system knowledge and the knowledge of how to interact with the vehicle to be able to respond to anything that might arise.

Host: All right. So clearly a lot of work goes into getting the people whether they’re flying on the vehicle or controlling it from here ready. But I imagine just as much if not more, goes into getting the vehicle ready. So after you’re done designing, doing all that stuff probably the most fun stuff again is the testing. Like what does it take? This is a brand-new spacecraft. What does it take to go from the drawing board to putting that thing on top of a rocket and putting people in it?

Tony Castilleja: Oh, it’s been just a journey from day one and it always starts off with what we call subcomponent testing. So let’s say in our vehicle has solar rays and batteries for power systems. Well, how does the battery work? Can you test the battery in the space environment in a vacuum chamber and get all that data? Okay, well now the batteries done. Well how does that connect over to the circuit board and how does that work? How does that work when it’s connected over to the console? Okay, well how does the Council then connect to the structure? And how was the primary structure react to the skeleton of Starliner.

Host: It’s like 10 million links in the chain.

Tony Castilleja: Yeah. Bottom line, it’s subsystem to integrated testing and NASA is working with us every single day shoulder to shoulder. And what we get to do is present our design test in the environment of the initial conditions and the box if you will of the environments that we’re going to experience in space and during our missions and NASA’s right there with us, you know, giving us an A+. Or if there’s lessons learned, we learn and we get back there on the testing floor and all of that, all of those checklists, all of those verifications come together toward our final flight readiness review which I used to do on space shuttle and we look around the room. We look at every subsystem and every engineer and say are we go for flight? And that’s that final grade report to ensure that safety for mission and crew.

Host: So you have all those different subsystems. Have you guys been part of any particular memorable task? Was there any system that you worked with when you know, you get that A+ afterwards? And you’re like, oh man thank you because I’ve spent the last like three months of nights working and obsessing over that system. And like how rewarding is it to kind of finally see that kind of — that link in the chain get locked in and then you can move onto the next one?

Tony Castilleja: Yeah, it’s the ultimate final exam.

Celena Dopart: Yeah. And multiple times right? So you go through one test. You finish it. You wrap it up with a bow and then you move onto the next one and they all build on top of each other. So, some of the tests that I’ve been involved in and are still ongoing are the integrated systems verification testing. So there’s so many different parts of that. It’s basically; it is part of that final exam. But there are so many parts. For example, we were down at KSC, Kennedy Space Center, where our launch complex is, doing emergency pad egress testing. So we did that recently which is pretty fun. You get to go from the top of the pad down to the ground in a matter of seconds testing those parts of the system.

Host: How did they get down?

Celena Dopart: How do they get down? We’ve got sort of slide wire system. It’s not the basket system that they used in shuttle but it’s a kind of — you can think of it sort of like a zipline. Emergency use only. Not for fun but it is pretty fun when it’s not an emergency. So we use that to get down but then we also, like I said, its integrated systems. So we get down to the ground and then have the big MRAP armored vehicles that take the astronauts and the ground crew out of the blast danger zone. So we’ve got all of those piece parts together and we test to make sure that the operations and the systems work together to actually meet the requirements that we need to. And so that’s prelaunch emergencies. We also do post landing. Tony mentioned that we do egress scenarios in the Boeing mockup trainer in Building 9. We’ve also done a couple post landing scenarios out in the desert at one of our landing sites. So we didn’t have a real vehicle landing of course but all the teams that are part of the recovery operations were out there in our ATVs waiting to go to, go recover astronauts and the vehicle. So we’ve done all that testing and there are still more that will burn down as we get closer and closer to launch. But each of those pieces is that so we are sure that our vehicle and the operations that we’ve designed around our vehicle and the systems work together the way that we expect and so nothing is a surprise on the day of launch or the day of landing just like Tony said.

Tony Castilleja: It’s a team sport and you know, my biggest or there’s about three of us that call the Boeing mockup trainer our baby and it’s because you know we spent very long nights ensuring that every part of the vehicle is to the right fidelity to what the astronauts need for use. For us, it’s not also about verification, making sure the checklist is done, it’s I’m thinking about the astronaut and their feeling and passion as they go into that vehicle. The understanding of how safe they’re going to feel in that vehicle. And so for us is not also you know, checking the box, it’s also getting it right and that’s that passion that we have. Whether it’s the day before Christmas or the day before New Year. Because we need this capability. We need it now. And to be able to be a part of that and be able to be a part of history and you know yeah, the checklist is the checklist. But to look back, which you don’t get to do very often at this amazing sprint to the launch pad and say, we built a living monument in Building 9. We built these simulators. We’re out in the desert and at the launch pad. It’s the best time to do what we do right now which is build a spaceship.

Celena Dopart: And you know what you said about checking the boxes versus making sure –

Tony Castilleja: Yeah.

Celena Dopart: — the astronauts love it and are passionate about it and can use it? It reminds me of my grad school systems engineering class. My professor would be so proud that I remember this. But the difference between verification and validation; verification is making sure that you meet the requirements that are set out. Validation is making sure that those requirements were the right ones to meet. That they actually do what we need it to do for the end-user and the full system. So that’s what we’re doing, right? We’re checking the boxes as we go along and do these tests but ultimately, we’re getting down the road to validation to make sure that hey, this thing actually works the way we need to.

Tony Castilleja: And my favorite when we were building the mockup trainer is that Celena was basically my customer. And so it was verification, validation, and then staring at Celena saying are you okay with this? So, you know, it’s also you know, a people perspective of how we get it done.

Host: All right. So all of this work is going into it and all this ultimately gets us to the mission. So walk us through the mission. We’re there. We’re on the pad. What unfolds?

Tony Castilleja: Right. So, we will be launching on the Atlas V rocket. So imagine yourself at Kennedy space Center. Our astronauts will actually be suiting up in the same rooms from the shuttle era, right?

Celena Dopart: I believe so.

Host: Yep.

Tony Castilleja: So you’re going to see elements of the past and the future all at the same time. We’ll roll out to Space Launch Complex 41. A huge hats off to United Launch Alliance. They built the crew access tower in the middle of an amazing rocket manifest to their other customers. And so they’ll go up onto the crew access tower to the Starliner which will not have a faring. It will be the capsule on top of the Atlas V vehicle. You’ll see it on the pad and they’ll go into the CST 100 Starliner very similar to Building 9 training. You’ll see those five seats in there for the first flight. There will be three crew members and a complement of cargo and in the future they’ll be those four crewmembers including a fifth paying passenger, right? And so, that will be the look and feel that you’ll see on the launch pad. You’ll see our NASA Mission Control Center that we’ve hired. Their tremendous expertise going through their final checklist again very similar to shuttle with the crew on the pad. The vehicle will be you know, smoky and with all the fuel and all the power you need to launch. We’ll do our final countdowns. People like Celena and our engineers, are going to be a part of that pole and is going to be go for flight. A typical mission will take about six hours to the International Space Station. So we talked about camping. It’s basically a long road trip. Going over to the International Space Station for autonomous flight the entire way of the journey. The astronaut can take over just in case to do a docking with the NASA docking system and the international docking adapter. Pressure checks on each side. Over the door and start your expedition mission. And then when you come back after your mission, you’ll get back into the Starliner. You’ll come back. About a six /six and a half hour flight if you will back down to earth to one of five landing locations in the western United States. As Celena mentioned earlier, White Sands has a tremendous history with NASA and we’re leveraging that capability in that landing location. Six landing airbags on the bottom of the spacecraft are revealed as you come back through the atmosphere after the heat shield is removed for a nice soft landing in spacecraft terms.

Celena Dopart: Parachutes to help with that.

Host: Parachutes too. Yeah.

Tony Castilleja: In the western United States. And the team on the ground accesses the crew capsule with as variety of ground safety and equipment to be able to open the side hatch. The same door you came in when you were on the launch pad and shake hands with those astronauts. Get them back and get them back to Johnson Space Center.

Host: Sounds pretty quick and clean.

Tony Castilleja: Quick and clean is what we want and we train for every scenario. But I’ll tell you, it’s a testament to an amazing team.

Host: Yeah. Have you guys been to any of the landing sites yet?

Celena Dopart: I have. I mentioned the recovery testing that we’ve done. We did that out a White Sands.

Host: That’s where I met you. Okay.

Celena Dopart: Oh is that —

Host: I was like yeah.

Celena Dopart: Okay.

Host: I remember. It was very hot.

Tony Castilleja: It’s a small world in aerospace.

Celena Dopart: Yeah. We were probably dirty and wearing dingier clothes than we are now so. But yeah. So I was part of the White Sands recovery team during that ISBIT test. And I know parts of the team have been out to some of our other sites to do site certifications to make sure they’re ready for our landings.

Host: So what did you think of the White Sands? For me it was almost like we we’re walking on the moon but really hot.

Celena Dopart: Yeah. It’s so cool how different, different parts of our country is. And to be able to leverage that sort of environment just flat and hard as far as the eye can see. It’s really cool that we have that right here and we can, we can utilize that. And that was, so we were on one of the old shuttle runways which is so cool to see. Just the vast expanse and for our landing, since it’s not a space plane, we don’t need to have a runway to land. It’s really basically a four kilometer target if you will. And so the way we we’ve chosen our landing sites is to make sure that there’s a four kilometer target of not much there, no dangers around so we’re not posing hazard to nearby cities or anything like that or other operations.

Host: Not landing in somebody’s backyard.

Celena Dopart: Exactly. So, it’s just cool to be there. And that was one of the first times where I really felt, this is happening. This is really real. I know the capsule that we were working with was basically a bouncy house. So that was the only thing that didn’t feel real but everything else. Everybody was so serious, so committed. So sure that we — this is how we need to ensure, verify, validate everything that we’re doing is here when we get an opportunity to come to one of our landing sites with the whole team and see how it will work on the real day.

Host: All right. Well, so all this testing’s coming up. What kind of the big stuff coming up for Starliner? I know there’s some test flights coming up and then you’ll be operational. What’s the really big stuff on the agenda coming up?

Tony Castilleja: We’ll be launching an uncrewed test vehicle as Celena has mentioned. Testing all the autonomous systems. Autonomous rendezvous and docking with our mission control centers in all of our engineers. The final integration with our Atlas V rocket. And then after that, once we get into all the flight checks and all the flight readiness reviews out of that crewed test flight —

Celena Dopart: Uncrewed.

Tony Castilleja: — uncrewed test flight and we’ll get all those checks down the line. That data is king. And that will verify the safety of our vehicle from our design and our verifications on the ground and that will get us ready for first flight with crewed astronauts with Boeing astronaut Chris Ferguson and our two NASA crew members. And what that does is ensures our safety of our crew which is our number one priority.

Host: It’s kind of like a big dress rehearsal almost.

Celena Dopart: Yeah. And I will say both of those flights OFT, or Orbital Flight Test, and CFT, our Crewed Flight Test. Both of those are still part of our validation efforts. So we will not — PCM1 is our first certified operational mission. So until that flight, we’re still in the test phase which is really kind of cool to be operationally testing. It’s such an exciting time to be on the program. Looking forward next year to those two flights. And shortly thereafter PCM1.

Host: And then once — so PCM, what does PCM stand for?

[Silence]

Host: Oh sorry.

Celena Dopart: What does it stand for?

[Laughter]

Tony Castilleja: Oh Post Certification Mission. Yeah, sorry.

Celena Dopart: Yeah.

Tony Castilleja: So many acronyms, so little time.

Celena Dopart: I said the whole thing without actually saying it. [Laughter] It’s after certification. Yeah.

Host: So that’s when you’re just flying crew members to the station for a regular mission?

Celena Dopart: Yeah so at that point, we’re really, NASA’s our customer, our paying customer and we’ll be flying NASA astronauts to and from the International Space Station. So before then our OFT and CFT is still validating and certifying our design.

Tony Castilleja: And well, that’s where the beginning of commercial space flight begins. If you look at what Boeing Starliner is and NASA Commercial Crew Program, NASA’s purchased tickets on every single vehicle at a flight rate of two flights per year. But as we mentioned earlier four, five astronaut crew members, that fifth paying passenger, fifth crew seat opportunity is available as we get into the later PCM flights or Post Certification Mission flights. And we go forward, you’re going to start seeing new international partners, international partnerships based on the great work we’ve done on space station and new people flying and going to space and conducting experiments in microgravity that will be a benefit, not just to NASA and the International Space Station, but to countries and people of the world. And that is truly the most exciting part. Is that we are creating the foundation for a new low-Earth orbit space economy and how cool is it that Boeing, a hundred years after building an aircraft and now connecting people around the world, is going to explore space and open that up to so many more future Boeing astronauts.

Celena Dopart: And so if the person who won Mega Millions is listening, there’s that fifth seat available.

Host: I was going to say, hearing that fifth seat, would you guys be up for taking the seat?

Celena Dopart: 100%.

Tony Castilleja: The amount of stuff and things we’ve learned with the Boeing mockup trainer and just building it, absolutely. Yeah and when you go into and you talk to every engineer and you get to know all of the intricacies of the system. Heck yeah. I would be on that flight. We are so committed to what we’re doing. I’d be on that flight.

Celena Dopart: Yeah. And I, I don’t know about Tony, but I’ve wanted to be an astronaut since I was really little. So that’s why I’m in this industry. That’s why I love my job. Working with them is the next best thing. But one day, I really do hope to fly on this vehicle that we’re building right now.

Host: All right. Well, this has been amazing. Before I let you leave, like, what’s the one thing you want to see more than anything coming up? Like what the one thing that’s got you most excited, whether it’s a launch, a landing, just seeing that first view of it in space? What are you —

Celena Dopart: Yes. All of it.

Host: Just all of it? Just say all of it?

Celena Dopart: I just — yeah. Just working on this program for the past two years and seeing us get closer and closer and closer. I just can’t wait to see it all come together. Each of these tests, those midterm exams that we were talking about, has brought us a little closer and felt more and more like the real thing. But I can’t even imagine what it’s going to feel like to be out at the launch pad on the launch day or out at the landing site on the landing day. I can’t wait to see Chris launch and come back. He is the person who hired me on so I’ve worked really closely with him for these past three and a half years at Boeing. And it’s just, I can’t imagine a cooler scenario then being part of the mission and having worked so closely with the people onboard. I just can’t wait for it to actually happen.

Tony Castilleja: Yeah. I mean my spark into human spaceflight started by seeing a space shuttle mission on a family vacation when I was 12. To work as an intern at Boeing on the space shuttle program and then full time. Be in mission control when STS 135 landed and hearing Chris’s voice. To be there when we were in the throes of the opportunity to build Starliner and having someone like Chris walk in and shake my hand and say hey, I’m now a part of your team. To building living monuments of trainers and to work with this world-class team with people who are truly living history. When we’re on the launch pad emotions will be many. But more importantly when we land, and we tell the nation and really the world that NASA has always been here. NASA continues to inspire and this is just one great giant leap forward into this new space economy. Boy, to be able to be a part of that and say we helped build this. We built this here, is just the best feeling in the world. And I can’t wait for everyone listening to be able to be in Florida, see it on TV, see it around the world and to spot the Starliner in space. It might inspire you to come join us.

Host: All right. Well, Selena, Tony I’m going to let you get back to the midterms. I know you’re excited to graduate. I can’t wait to see more from Starliner. Thanks for spending a little bit of time and showing, telling us all what’s going on and what there is to look forward to. I really appreciate it.

Tony Castilleja: We’ll see you on the launch pad.

Celena Dopart: Thanks so much for having us.

[Music]

Host: Another big thanks to Tony and Celena for coming on the show today. If you want to learn more about Starliner or the Commercial Crew Program, you can always said online to NASA.gov/commercial crew or head over to social media. You can find them on Facebook at NASA Commercial Crew or on Twitter @commercial_crew. And as always, if you have any ideas for podcast or something you want to hear more about, head over to social media and use that hashtag #askNASA to submit your favorite idea. This podcast was recorded on November 1, 2018. Thanks to Alex Perryman, Pat Ryan, Norah Moran, Kelly Humphreys, Kyle Herring, Steve Siceloff, Kerry Arnold and Gary Jordan. And thanks again to Tony Castilleja and Celena Dopart for coming on the show. We will be back next week.