“Houston We Have a Podcast” is the official podcast of the NASA Johnson Space Center, the home of human spaceflight, stationed in Houston, Texas. We bring space right to you! On this podcast, you’ll learn from some of the brightest minds of America’s space agency as they discuss topics in engineering, science, technology and more. You’ll hear firsthand from astronauts what it’s like to launch atop a rocket, live in space and re-enter the Earth’s atmosphere. And you’ll listen in to the more human side of space as our guests tell stories of behind-the-scenes moments never heard before.

John Lewis, Orion ECLS (Environmental Control and Life Support) system manager, discusses how the Orion spacecraft will keep the crew inside comfortable – and more importantly, alive – during a mission into deep space. This episode was recorded on October 2, 2018.

Transcript

Gary Jordan (Host): Houston, We Have a Podcast. Welcome to the official podcast of the NASA Johnson Space Center, Episode 79, Livable Space. I’m Gary Jordan, and I’ll be your host today. In this podcast, we bring in the experts, NASA scientists, engineers, astronauts, all to let you know what’s going on here at NASA. So you may have heard our previous episode talking about Apollo 8, the first mission where humans went to the moon. And we’re going back. This time it’s on Orion, NASA’s new deep space vehicle. And today we’re talking about how Orion will keep the crew inside comfortable and more importantly alive and reliably too. We sort of take for granted that we can walk outside and breath fresh air in a nice pressurized atmosphere, but that all has to be created in space and sustained too, and it can be pretty hard. Every exhale that you let out has some carbon dioxide, and even just a small amount can have effect on the environment over time. So what do you do about it? Discussing this topic is John Lewis, Orion ECLS, that’s Environment, Control, and Life Support system manager. We go into how Orion is designed to make sure astronauts have a livable and reliable environment inside the space craft when they travel through the not so livable deep space.

So with no further delay, let’s to right ahead to our talk with Mr. John Lewis. Enjoy.

[ Music ]

Host: John, thank you so much for coming on the podcast today.

John Lewis: Yeah, thanks for having me. This is really nice.

Host: We’ve talked a bit about Orion. I think at this point we have quite a number of episodes, but we really haven’t gotten into I guess one of the most important parts of Orion, and that’s keeping the humans inside alive and comfortable, which is a huge part of building a human rated spacecraft, and that’s what this is all about. So we’ve sent, you know, probes, rovers, all over the solar system, but the furthest humans have ever gone is around the moon. I think Apollo 13 actually when it wrapped around the moon–

John Lewis: A little further, yeah.

Host: Had the greatest distance compared to all of them. But let’s kind of pull back and talk about keeping humans alive. What, just basics of what do humans need to stay alive in space?

John Lewis: So, I kind of put it in the thought of if I put you in a box, right, what’s going to happen, first, second, third. Right. And the first thing that’s going to happen to you is the carbon dioxide that you’re breathing out from the food your metabolizing is going to start getting to an elevated level, and your body is going to go carbon dioxide is at an elevated level, I need to start breathing more, because that’s how I get the carbon dioxide out of my body. So that’s the first thing your body will notice, and that’s the thing that we react quickest to. Because if my CO2 removal device doesn’t work, boy, I’m going to get into trouble pretty quick because my levels are going to get up, so I have single digit minutes to hours depending on if I’m in a space suit or I’m in a space craft, and so I’ve got to react to that. The next thing, actually even before that, I’ll also get wet because everything you drink, half of it goes in the bathroom, and half of it comes out your skin and your breathing, right. So your half water comes to the top, half of water comes out the bottom.

And that water coming out into the air is going to start condensing on the cold surfaces of the spacecraft. As the spacecraft is dealing with the cold, the space on the outside, we’re trying our best to keep the walls about at 60 degrees Fahrenheit. And so like a glass here on Houston on a humid day will start condensing on the inside of the spacecraft. It’s an issue, most of our electronics are designed to be able to handle a certain level of condensation. In space flight, condensation happens, but if you let it persist too long, it would become an issue. And actually humidity is first because you’re putting out a lot of humidity, and it takes a little bit to raise those levels. You have more time for oxygen. You have halves of days, depending on your volume, because the amount of oxygen we’re used to dealing with in the air is about two-tenths or 20 percent of the air is oxygen. And so I can breathe down that 20 percent to around 15 percent, and I’m probably still okay, maybe a little lightheaded, but I’ve got a lot of room there. Where the CO2 is a fraction of a percent to a percent, and where it becomes a problem is at one or two percent, and so it takes a very little bit for it to start to become a problem and my body reacts to it.

Host: Wow.

John Lewis: And so that’s why oxygen, I got a little bit of time. And then on the longer scale, water will probably be your next issue. We like to drink about two and a half liters per crew per day and keep them well hydrated. If you go for a long duration of time, like Apollo 13, where they limited their water, you start to get effects from that, and so you’ve really got to be careful with that. Longer than that still, for my area, I have to worry about the trace contaminants, right. So you get in a new car, you have that new car smell. We even have the new spacecraft vehicle smell that we had to clean out when we launched ISS.

Host: Nice.

John Lewis: And so, and so you have to watch for those things that make a locker room stinky, right. And you have to say those, over time, they’re not leaking out anywhere. They stay in the vehicle, and so I have to clean those out because some of them, like carbon monoxide and ammonia, which are actually metabolically generated from us, will get to a level where it’ll become an issue in days. And so we’ve got to think about how we clean that out of the air. So the main part of the job is just keeping the right amount of, keeping the CO2 away from the crew, keeping the right amount of oxygen on the crew, keeping the air clean, giving the crew good water to drink, and then being able to take that water, whether it comes in the air or comes in the bathroom and get rid of it and put it in a place where we don’t need. The other thing we have to worry about is when everything is working great, my mission is easy, right. My whole experience is great. But I have to plan for what happens if it breaks, right. And so I planned for two what happens if it breaks.

I plan for one what happens if it breaks, which is, what happens if my system breaks, right. What happens if the thing that pulls CO2 out fails? Well, I’ve got to have another thing that pulls CO2 out, ready to go, flip the switch, and Orion different than on ISS because on ISS, big spacecraft, lots of volume, I have time. I also have friends in the Russian segment that have other CO2 removal devices, so we can figure out how to make those work. And if it’s broken, I can spend an afternoon fixing it and get it back online. In Orion, I am a tenth if not a hundredth of the size of, you know, of the ISS at 600 cubic feet, so very small, and I’m also doing key critical maneuvers, and so I don’t want to have something break that makes me stop and engine burn or something like that. So I want the computer, if it’s good, to say, wow, my CO2 removal system failed. Flip on another device, let’s get rolling again, and have those online and ready to go. So, unlike my experience working at ISS where we had what we called ORUs or On-Orbit Replaceable Units, where it’s built to unscrew these two things and pull it out, all of our stuff on Orion is flip the switch, turn the other one on, and it’s ready to go.

The other thing I have to worry about is what if something else fails. What if I have a fire? What if I have a hole in the side of the cabin? Or what if I have something spilled that is toxic to the crew? And so there I have to think about putting the crew in a safe space. In the case of a depressurized cabin, I have to one, allow the crew time to get in their suits, and so I got to, if I have a hole in the cabin, I can support up to a quarter-inch hole poked in the side of the cabin, however it happened, and I’ve got to maintain the pressure above 8 PSI, so slightly a little more than half of our atmosphere but with enough oxygen that they won’t know any difference. I raised my oxygen actually up to about 4/10 of the environment is oxygen. I can go that high just to keep, to keep the crew from getting dizzy or lightheaded.

Host: Right.

John Lewis: And so, and so, I’ve maintained that pressure, and the crew gets their suits on. They do their leak check, and then they let the cabin pressure go down. The other thing I have to think about is what happens if I have a fire or what happens if I have a laptop that batteries cook off? And so I’ve got to think, you know, the odds of that happening are very slim. We spent a lot of effort making sure that fire doesn’t propagate, and we pick the right materials, but fire happens, right. You’re always going to have the fire extinguisher. So, I got to think about the fire extinguisher that puts the fire out. I’ve got to think about the masks that the crew puts on because in that small volume the air is going to get very bad, very fast, and actually the first thing the crew is told to do, if you smell anything funny, put that mask on, right. And then start looking because it could get up on you really fast. Then I’ve got to be able to provide them with remote sensors because in a fire case, everything is going to be turned off, right. And so I want to have a stand-alone sensor that says this is what the air is like outside, and it’s okay or not to take your mask off wherever you found the fire.

And then I’ve got to have a way of cleaning up the cabin. I’ve got a, and so what we do is we take out our normal cabin air filter, which is just a dust filter, a HEPA filter, to clean up the cabin, and I drop a box of charcoal and other magic rocks, right, that’ll absorb and catalyze the contaminants that come off the fire and turn it into breathing air again. And so, all these cases are things that ECLSS has to think about in that contingency case, you know, on whether I failed, I lost a water tank, I’ve got to have enough water to get me home. Or, hey I got a hole in the cabin. I got to make sure I can support the crew in a depressurized cabin for up to about six days home.

Host: Wow. Okay. A lot of layers there.

John Lewis: Yeah, sorry.

Host: No, I like the, it’s good, less that, we have a lot of time to break it down. Going back to your box analogy.

John Lewis: Yeah.

Host: I like that just because if you were to just put the crew in a box and did nothing, here’s the series of events that would happen, starting with carbon dioxide. How little wiggle room you have. That’s insane. So let’s talk about the carbon dioxide removal system and kind of compare it to different things. How does that work? How is carbon dioxide actually scrubbed from the environment?

John Lewis: Yeah. So what we’ve done in past programs, actually all the way back to Mercury, is we used a chemical called lithium hydroxide, and lithium hydroxide, if you want to play with the stoichiometry, it does a couple different steps and makes lithium carbonate, and it grabs that carbon dioxide and pulls it out of the air. And so it absorbs it, but now that you’ve turned that lithium hydroxide into something else, and it no longer can pull CO2 out, and so it’s expended. And so what we’ve, what has been developed is amine chemical, amines will grab CO2 and grab water, and if you, in a cabin atmosphere condition, they’ll hold on tight to them, but if you expose them to vacuum and keep them about the same temperature, they’ll like go. And so what I do is I run the cabin air through it or the suit air through it, and it grabs the water, and it grabs the CO2, and it holds on. And then I expose that bed to space vacuum, and it let’s go, and so I have a series of alternating beds. Half of them are exposed to the cabin, half of them are exposed to the crew, I’m sorry, half of them exposed to the cabin, half of them are exposed to space–

Host: To space, yeah.

John Lewis: And so then I alternate cycling those beds, letting go of the CO2 and the water overboard. Very similar to the way ISS does it. ISS has a much bigger version of it, and what it does, since ISS wants to recycle their water, it grabs the water and grabs the CO2 and then throws the CO2 either to a tank to be turned back into oxygen again and throws the water back into the cabin. In my case, I really, all I need to do is just get that stuff overboard like shuttle and pass programs and kick it off. And so the system is a little box about, oh, a foot and a half by a foot by a foot, and every 10 to 20 minutes it cycles.

Host: Oh, that fast, wow.

John Lewis: And it just, it goes through and cycles. It was actually first used on the space shuttle on the extended duration orbiter mission. So the long duration orbiter that when Columbia was outfitted to be that EDO mission. It was called the RCRS then. It was a very big unit, and it was very cumbersome. And through development we’ve been able to make it smaller and smaller and more compact and actually only work with one single motor that rotates four ball valves and makes it all line up and– because the concern is you never want to have, I have half of my systems exposed to space vacuum, half exposed to the crew, and I never want the two to meet. Right. I don’t want to expose the crew to space vacuum, and so the way the valves actuate, it assures that what you do is it closes off from the crew in the space vacuum, and it actually equalizes the two beds, one that’s been a vacuum and one that’s exposed to the crew. And so I only lose half of my air. I get to save a little bit of my air, and then it cycles over and dumps the air overboard and then opens the new bed up to the cabin.

And so it’s, we’ve done actually quite a bit of testing on this, and we’ve done it in suited operations. The advanced suit development guys were also looking at this same approach on their advanced suits because it just allows you to go deeper and deeper in space without carrying expendables and, you know, with lithium hydroxide, it’s a dead end.

Host: Yeah.

John Lewis: I have to throw it out or send it back home to get refurbished, and it’s just not with it.

Host: So how about these beds, how long in these 10- to 20-minute cycles can you use it before, do they need to be switched out kind of like a filter?

John Lewis: They operate on order of years.

Host: Wow.

John Lewis: We’re trying to get, we seen a unit that we ran in the test labs for about six years, and we’ve lost about 20 percent of the performance. So, most of our space flight hardware on Orion is designed for about five years and five uses, five flights. The years is more of seals and things like that, that’ll eventually go bad. And the launches, the biggest driver is how many times you have to go up and down on the raw hit and land and hit the water. And so all those impacts is a structural thing, and so it starts cracking it up. And so you’ve got to be wary of that. And usually our life, just like the Mars Rovers, right, we all say well the mission is going to be this short, and then we find out, oh, no, the mission was much longer because up front I’m looking at these really, well what’s the worst case? What’s the worst case of all these things? But then when you find out, you actually have margin in the device. And so we’ll see. I’m hopeful that we’ll get a lot more life out of them.

Host: Yeah. Now this may seem apparent, but there’s a reason why we’re just using these beds to sort of dump the CO2 and all the bad stuff outside and not bring it back in like ISS. What’s that reason?

John Lewis: And so if you look at ISS, ISS has a great system where, you know, at one time we had a system that can take the carbon dioxide that you breathe out and mix it with a little bit of hydrogen that you get from your oxygen generator, and you let the carbon go overboard, and you turn it back into water that you then turn back into oxygen. And then you take all your humidity condensate and urine, and you run it through a couple filters and distillation steps and everything until where it’s drinkable water again, and then I’ve got a water electrolysis unit that I take water and run it through kind of a reverse fuel cell, right, to where I put water in, and it turns it into hydrogen and oxygen, and I can breathe that oxygen, it’s like the Russian electron. And then I use that hydrogen again to help me recover the CO2. But all of that takes up several rack bays in the International Space Station, so imagine something two meters tall by, you know, a meter wide if not a little more, and there’s a lot of equipment in there, a lot of expendables. And so I’ve got to think about lightweight.

I’ve got to think about it’s got to work and if I can find a system that has a single valve, you know, then that meets my needs. All I have to do is two things. I have to keep crew going for 21 days, and I can, up to four crew. And then if I go dock to anything, whatever, the Space Gateway or wherever that may be, I’ve got to be able to hang out there for at least six months. So my seals and leakages and things like that will be sized by that. But I can do that with classical gas storage and water storage and things like that, and we’ve yet to get to the state of the art where the recycling equipment is small enough, you know, we’ve yet to get the recycling in the box, right.

Host: Yeah.

John Lewis: And there are people that are pushing to develop that, but right, it’s always, it’s always out there. And so right now the best weight option is just to let the water and the CO2 go overboard for spacecrafts like Orion but for a long duration. As soon as you go past a month or so, that’s where turning the water back into drinkable water and turning the CO2 back into breathable air is very key, because then you don’t have to bring up all those expendables for that.

Host: Yeah, that’s a huge difference. ISS is, I mean it’s been continuously habited for years, but for Orion you’re talking about 21-day missions–

John Lewis: Twenty-one days.

Host: Up to 21 days, so yeah, you don’t really need to have that sort of redundancy. It’s too much weight, too much mass.

John Lewis: Yeah, keep it simple.

Host: Yeah, keep it simple. Yeah, I like that. Thinking about the box analogy going down, I think the next one was humidity that you had to be concerned about. Is it the same system, or is that a different–

John Lewis: It’s the same system in our case.

Host: Okay.

John Lewis: The swing beds will absorb humidity and CO2 at the same time. In past projects all the way back to Mercury and the current EMU does the same, uses what we call the condensing heat exchangers, basically like an air conditioner in your house where you run cold water through a set of fans and you run air on the other side, and the water just condenses out. You have to be tricky in that system because it’s microgravity, right, and the water goes where it wants to go.

Host: Right.

John Lewis: And so you have to make the passages really small, and you’ve got to put a little bar at the end that sucks the water out and then separates the air from the water, so you have to have a spinny whirly gig thing that separates the water and then puts that into a tank and then vents that overboard or gives it to your water processor. And then the spinny whirly gig thing is a very complicated, delicate device, and we know how to do it, and we’ve done it since the shuttle and station, but it is, it is a wear item. It’s a power item, and this aiming system absorbing both of those just makes it much simpler. I’ve got three motors, I’ve got three swing beds, individual and independent units. I need all three to exercise, exercise to keep your bone loss and everything down.

Host: Yeah.

John Lewis: That’s a real high metabolic rate, right, so I’m generating a lot of CO2 and humidity. And so, and so I’ve sized for that, but I can go down to a single unit and still get home. So I actually can suffer a couple failures of units, but all it takes to operate these aiming swing beds is three valves, one on each unit, and it just is a valve that moves 270 degrees, and every ten minutes it does it. So less moving parts the better, right. And you worry about the chemistry of the amine and things like that, but the amine has been used in nuclear subs for half a century, right, as soon as we started being able to go down and staying under water for a long period of time. They started looking and amine there. Their amine systems take advantage of gravity though, and they’re able to, because it comes out as a liquid, and this system has a way of suspending it on a solid and keeps it from, you know, coming out in the air. And so that’s what’s been very advantageous is that dual removal.

It’s different than the ISS unit because the ISS actually has one part that holds the water back and the other part that pulls the CO2, which is nice, because if you mix them all together, it’s hard to separate them, right. Hard to separate the CO2 in the water. Yeah, but in the ISS system, it automatically does that and keeps the water back in the cabin to where the air conditioner can pick it up so you can drink it again.

Host: Ah, okay, so it’s the part, the logic of that is for the recycling part of the whole– yeah.

John Lewis: The recycling, right. I want to, the way I treat my CO2 is different than the way I treat my water.

Host: Right.

John Lewis: For me, it’s all going overboard, I don’t care.

Host: So you can mix them, yeah.

John Lewis: It’s all good, so it doesn’t matter.

Host: That’s actually interesting, one thing you were talking about was it’s such a small environment that you actually have to think about the environment based on what you’re doing in it. So if you’re working out, more CO2, more humidity, that requires you kind of jacking up the systems on your environment a bit just to deal with that.

John Lewis: Yes.

Host: That’s funny.

John Lewis: And you have to think about well what happens if I don’t do that, right? Well, my CO2 levels will get high or my humidity levels will get high and I’ll start condensing on the shelves, and I’ll worry about microbial growth in the cabin and things like that. And so we are, when you put yourself in a really small environment, you realize how much you’re driving that local environment just by what you do.

Host: Yeah.

John Lewis: So.

Host: So another thing that you were talking about was redundancy. Part of your design is you want it to be, you want it to have those redundant systems so if something were to come up, it could be easy to go to another system. How do those work? Are they the same? Is it just the same system but multiples, or is it–

John Lewis: In most cases, we have what’s called a like redundancy to where I have, like I mentioned before, I have three swing bed units. I need all three for exercise, but I can go all the way down to a single and still get home. So, in that case you have to be really sure that you’re not going to have a common cause failure. You’re not going to have–

Host: Right.

John Lewis: This one thing of this design is flawed, and that’s why we spend a lot of effort in developing the chemistry, exposing it to as much environments as we can. We have a development swing bed that we launched up on orbit, the cameras on the ISS, and it’s slightly different. It had a way to keep the water in the cabin, because the ISS didn’t want us to waste our water, but we were able to expose that to the space craft environment, because it’s really interesting. You’ll find like spacesuit guys and ECLSS guys will always get something broken due to a very small trace contaminant that you will learn the name for the first time, you know, on that failure. The spacesuit was affected by thiolate esters. And it’s like, what’s a thiolate ester. Well, it’s what affected the spacesuit, and it caused its cooling pack to not work right, and it was just this chemical that was found in part per billion levels, right. And that part per billion levels changed the way that system performed.

And so when I think about this amine chemical, I want to expose it to as much of the spacecraft smell, as much of the human smell, and make sure that it works over a long duration. Then we take those units, and we expose them to launch load environments and to shock environments and to landing loads environments and high temperature and low temperature, and we make sure they work through all those. And we actually make sure they work to a percentage over what we ever expect on space, one, because we don’t totally trust our math, right. I trust my math, but I don’t want to be so cocky to say that I didn’t make an error, so I’m going to push my testing to a little further and get that confidence that over and above that this unit is sized for that so then I can have that confidence of, yes, you can have three of these devices, and you’re going to be in good shape.

Host: Yeah.

John Lewis: There’s other areas where we have a dissimilar redundancy to where I have my waste collection system, which is running through a spin separator and all these magic parts to separate the urine from the air and to dump it overboard, but if that breaks, partially driven by I didn’t have room for two of them, I looked at a much simpler urine collection system, which is basically a bag that I can then hook up and vent overboard, but peeing into a bag when you’re in microgravity isn’t as easy as you would think, right. And so there’s some mess involved and some things you’ve got to think about, but we’ve had good ISS experience with that, and so I’ve got a, in that case it’s a dissimilar redundancy where I’ve got something that’s a different approach that allows me to have a different way of getting home.

Host: Is that part of it too, the waste management, is that part of the ECLS systems?

John Lewis: Yes, waste management is part of ECLSS. We take care of everything going in and out of the crew, except food, the food guys take care of that and they do a great job of it. They make food taste much better than I’ll be able to so.

Host: And that’s another part that’s not going to get recycled like space station, right. That’s another one that everything goes overboard, right.

John Lewis: Right, yeah. Everything goes overboard. Urine, we vent overboard, and then fecal, we store in a can.

Host: Oh.

John Lewis: If we are ever going to like a lander, we probably will do like what Apollo did is where they took all their trash and threw it in the lander before they cast off the lander when they came home. So they took all the rocks out, put the rocks back in the command module, and they put all the waste into the crew module, I mean into the lunar module to get home. Similar to what we do on progress vehicles on ISS, right. Get all the good stuff out that you want, then you take all the bad stuff. You put it in there as best you can, and the challenge always in space flight is just like Murphy’s Law, you know, you unpack a box, and it never packs back the same. And so fitting it all in the same spot is the challenge to do that.

Host: Okay. But the difference with Orion is you have not as much room to play with, kind of like Apollo, right?

John Lewis: Yeah, we’re, we are, so the space shuttle was 2000, 2100 cubic feet. Shuttle was 350 cubic feet, that’s pressurized volume. We are about 660. So we are much more Apollo-like and so we get that tight volume, space is key. That’s why if you look at Shuttle hardware and you look at the accompanying space station hardware, space station hardware is very big. It’s loads weren’t greater, and so it wasn’t driven by, hey, I’m going to have a rougher environment, but whenever you want to be able to remove something, you’ve got to have big knobs on them and make it to where it’s easy to pull it out and the seals were repeatable. And so a lot of space station hardware is driven by on-orbit replacement.

Host: That’s interesting.

John Lewis: And so we’ve got to drive things small again because we’ve got to fit everything under the floorboards. So when you see the crew, the bottom two crew in Orion and sitting on the back where their feet are and behind them and up along the sides is all where the ECLSS equipment is, and it fills it up full. And we are, I wouldn’t like to admit, but we don’t totally fit just yet. We are at our critical design review, and it’s part of the design process. It’s is working all the interferences and everything like that to make sure it fits. And so that’s why having something that’s on-orbit replaceable is very hard because the space is very tight for us.

Host: Yeah. That’s one of the big challenges is okay now take all this knowledge, shrink it–

John Lewis: Yes.

Host: And make it super redundant–

John Lewis: Yeah.

Host: Which is, increases weight.

John Lewis: Yeah, in some ways we’re challenged because we’re like the shuttle, right. I have a shirt-sleeve, 14.7, sea level environment, where Apollo had the 5 PSI 100 percent oxygen environment. The disadvantage of that is from flammability concerns that Apollo had to deal with the entire program, but there is an advantage of if you get a hole in the cabin in Apollo in a 100 percent oxygen vehicle, you can get in your suit and go down to low pressure because you’ve already gotten all the nitrogen out of your system. In the space shuttle, they didn’t have to worry about that because they could find a runway. One, they were a big volume. They could find a runway at 135 minutes. Right. I’m away from the Earth. My quickest trip home is six days. So if I have any failure, whether it’s a hole in the cabin, I lose a water tank, I lose and oxygen tank or a prop system fails, we always got to be able to get home in six days, and so I’ve got to think about how I keep the crew, you know, going in that configuration, and one of the challenges from when I’m six days from home, I’ve got a normal body’s level worth of nitrogen in my body, and if I got to jump in a spacesuit, I’ve got to do prebreathes like the crew is going EBA.

Host: Yeah.

John Lewis: Well, but the only thing is, I’m going to be in my suit, and I can’t go as low in pressure. So what we did is we allowed the suits to, normally a spacesuit operates about at a third of the atmosphere, about 4 PSI. EMUs operate about that. And we did prebreathes on shuttle in the cabin environment at a pressure of 10.2, ISS airlock does the same thing, so about two-thirds of the environment. The lower you go, the more chance that nitrogen has to come out of your body and give you bends and give you that issue. And so, but spacesuits don’t like going in high pressure, because the higher they are, it’s basically like a balloon that’s holding you in, and you’re really stretching hard on that suit. And so the guys in the suit development had developed a suit to handle up to 8 PSI, and that allows you to do a prebreathe to get all the nitrogen out of your blood and to allow you to go down to a lower pressure. So that’s why we’re kind of in this, we’re kind of like ISS, and we’re kind of like Shuttle, but then we’re kind of like Apollo, and so you kind of have the worst of both worlds, right, in some cases, right.

And every time, every time you make a spacecraft from Mercury and Vostok to all the way to the infinite one built, you’re going to have to think about how do I optimize this vehicle with the technologies I have? How do I get it to where everything works at its best and I got the most capacity, and you’re always going to be at that leading edge of your technology. And so we do a lot of analysis and ringing hands and testing and things like that to assure that we’ve got all the capacity we need, and there are things and areas where I lose a little sleep going well I hope we don’t ever get in that situation. Because I do know that we are right line on line, you know, to be able to make it work, but that’s what space flight is.

Host: Yeah, yeah. No, I guess, so the logic behind not doing 100 percent oxygen like Apollo was the flammability thing.

John Lewis: Yeah.

Host: And that was priority number one. No, we’re not going to have, we’re going to make sure that it’s going to be a safe environment.

John Lewis: Yes.

Host: I think at a certain level of oxygen is where it will sort of distinguish over time.

John Lewis: Yeah, so what you do, Apollo did it and Mercury did it because there’s only so much weight you can throw uphill, and our space capsules were built to weigh about as much as our nuclear warheads, about 3000 pounds, because we were using missiles for it. And to make that fit, because we made such light nuclear warheads, we had to make light spacecraft, which is kind of a weird flip, and so that pushed them to say, well, a cabin that only has to hold 5 PSI or a third of atmosphere is a lot lighter than has to hold a full atmosphere. But we’ve gotten more capable rockets now, and the flammability concern, as we learned with Apollo 1 is severe. And so, at Apollo 1, they set up a test lab out at White Sands facility in New Mexico, and they burn everything, right. And they prove that when you set a strip of this and a chamber at the right conditions that that fire puts itself out before it gets a certain length, and so we make sure all our materials self-extinguish. And that is a function of what percentage your oxygen is. So, if you look at the air right now that you and I are breathing, I could look at it in two different ways. I can look at it as I’m at 14.7, 15 PSI, and about 3 PSI of that is oxygen. And then about 11ish PSI is nitrogen, and there’s a whole mess of CO2 and water and other things.

Host: Yeah.

John Lewis: What you and I care about is that partial pressure of oxygen. Because what happens is, is when I breathe it in, it’s the partial pressure across my lungs where I’ve got blood with a certain pressure of oxygen and air, and it’ll actually diffuse across if I have the right partial pressure. So if you go on the top of Pike’s Peak, where it’s about 1.8, 1.9 PSI partial pressure, you’re going to start to feel a little tingly. Your teeth start to feel numb. You’re decision processes aren’t that good. Now, fire on the other hand, the way it works is it works mostly on percentage. So it says, I first order don’t really care whether your nominal atmosphere is at 14.7 or 10. If you get over 30 percent, then certain materials will burn more, and so the higher and higher you get in oxygen percentage, the fire stays at. And so what I have to do on a spacecraft is I have to keep them—what’ll happen is when I get in the lowest pressure, and what sets my lowest operational pressure, which is 9.5 PSI.

So why do I change pressure at all? Right. Why would I even do that? I may come up to a spacecraft, you know, I would love to stay at normal atmospheric pressure like station does, but I may come up to a spacecraft that’s at a slightly lower pressure. I may have a lander coming up from the moon that only designed itself to be about a 10 PSI vehicle because it would become a lighter vehicle. So I’ve got to be able to come down in pressure and meet them. So I try to get a good range to where I can operate at the highest high and the lowest low, and what sets my lowest low is the percentage of oxygen, maximum percentage I can have before I worry about fire, crosses over the line of where I just have enough for the crew to breathe. And so if I get any lower pressure, I’m either going to set a fire, or the crew is going to get dizzy. And so, and so that’s what keeps me in that box, and so you basically have to look at what my materials are. So materials are very key at understanding what burns and what I’m allowed to do oxygen wise.

Host: Yeah. And that goes to some of these other things that you touched on, which was emergencies, you know, what happens in depressurization event? What happens in the case of a fire? The first case, the first offense against a fire is the environment itself, actually introducing nitrogen into the environment and bringing that oxygen down, testing all your materials, there’s all these different levels. But you were talking about some of the procedures for fire. You’d mention extinguishers and masks and stuff. How does that work? Is that part of the design to have these things kind of at hand?

John Lewis: Yeah, it’s very interesting. I talked to Dr. Pedley, who is our materials and process specialist, and he, I said, well, you know, tell me a little about what we do for fire. And he says, well, I make sure that your materials are good with certain margin up to your environment so that no matter how you light them they won’t propagate. I make sure that all your ignition sources, things that will spark, will be arrested and I won’t have a, you know, a sparking event happen. I’ll have a circuit breaker that’ll pop off and keep that from happening. And so you control the ignition source, you control the materials, and so that keeps that flame from happening. And I say, oh, great, I can save weight and not have a fire extinguisher. He goes, no, you’ll always have a fire extinguisher, right. Because it’s, it is, you’d never know absolutely, and so what we’re actually, the biggest thing that drives us, so I got two areas I worry about for fire. I worry about it in the ECLSS bays and the bays where all of the electronic equipment is. So the parts under the crew’s backs and under their seats where all of the computers and everything and the life support equipment are running, and then in the open cabin, I worry about fires in that area.

And there’s two different ways I fight it. The interesting thing about fire is at microgravity fire actually self-extinguishes rather nicely. Because what happens is on the Earth if you look at a candle burning, and the flame is going up, it’s making heat, and it draws up, and the CO2 goes up, and it brings in more oxygen. If you have fire where you have no free convection or you have no up, the fire basically turns all the oxygen in that area to carbon dioxide and self-extinguishes that localized fire.

Host: Oh.

John Lewis: If you don’t have ventilation. I keep ventilation in the cabin. I keep a big fan going on to keep the air well mixed or keep the guy breathing connected to my equipment pulling CO2 and humidity out and oxygen well mixed. But actually when we see a fire in the cabin, the first thing the smoke, I have a smoke detector looking for that, the first thing that smoke detector does is it turns off the cabin fan. If you turn off the cabin fan, you stop that air moving, and you stand a good chance that the fire will self-extinguish. Below the bays where all the equipment is, what we did is we said if we can rate the materials there for 10 percent over our normal materials level, so our normal oxygen concentration, the highest we expect to get, then I’ve got margin that they really won’t burn. So, if at high as I’d ever get in Orion is 30 percent, all my materials were tested to 40 percent, and they showed that, yep, you can light it with 10 percent over, and it self-extinguishes. And we also showed, we lit fires in the electronics boxes, and we showed that they actually pull all the oxygen out of the electronics box and self-extinguish rather quick.

Host: Oh.

John Lewis: Actually, the guys at WSTF, they’re great guys, they love burning things and telling you great stories of how it burned, and they myth-busted that one. They did a normal electronics box, and the fire self-extinguished. So then they threw in more material, and it self-extinguished. They threw in foam and anything they thing that would just ignite, because you never know, some assembly process got some in there, some escaped, and it’s also fun to see how far you can go. And they ignite it, and it self-extinguished. So it gave us the confidence that, no, that design will self-limit fires. So, we early on in Orion had an avionics bay fire suppression system similar to shuttle, had an avionics bay fire suppression system, and when you’re going uphill, you don’t want to think about it. You just flip the switch.

Host: Sure.

John Lewis: But they also used air to cool their electronics. But Orion because we are, I can operate the cabin with a vacuum in it, right, because I’ve got to be able to go spacewalk or I’ve got to be able to get the crew in a depressured cabin, all my electronics is cooled sitting on a cold plate. What a cold plate is, it’s just a piece of metal with some tubes running through it that the active thermal system is running through water or coolant, propylene glycol water coolant. And so their electronic devices are bolted right on it, and the heat goes into that. And so there’s no moving air. I don’t have to have an air conditioner down there, and so with no moving air and what my material is rated over a certain amount, the fire safety folks at Glen Research, White Sands, and here felt that, no, you’ve got enough margins that you can get rid of that fixed fire suppression system.

Host: Yeah.

John Lewis: And the cabin, I’ve got to worry about all things crew, right. You know, I’ve got cloth, I’ve got laptops, I’ve got all these things that can be variable, and I’ve got ventilation that’s pushing around. And so what we actually made a change from past projects and programs and we’ve actually tested a lot of this out on ISS, the kind of fires that really worry us are battery fires. And why so, google laptop battery fire and watch the video on YouTube or wherever, and you will see that there is a lot of stored energy in these little devices. Everybody wants their device to show really bright colors and show the last two or three movies while you’re stuck on the airplane and be bright and vibrant and last for a long time. That takes power. And so battery makers are getting smarter and smarter of making more and more energy in a much smaller space. So it’s got a lot of high-energy density. And very rarely those things will short out, and when they short out, they will cause a fire.

And so that fire is self-generating and will propagate, and I can’t really do anything about materials wise because it’s just, it’s just letting that energy out. And past fire extinguisher systems we’ve used have been like halon and carbon dioxide, and those just inhibit the fire from interacting with the air. It keeps it away. And the problem is that for a paper fire, well that’s great, because it take the oxygen away and it stops the fire, but for a battery fire, it’s making it’s own heat. As soon as the oxygen gets back in there again, it’s going to light off again. So what you got to do is you got to make the heat go away. And so we’ve gone to a water spray fire extinguisher.

Host: Oh.

John Lewis: Because when you spray water on it, that water turns into steam. When you turn that water into steam, you’re pulling a lot of energy out of that fire to turn that water and liquid into a steam, into a vapor. And so when you do that, you cool the fire way off, and so we said, yeah, we definitely have to go to a water fire extinguisher and actually work with ISS, and they actually, we developed a water mist fire extinguisher for them to prove that it would work on ISS and have confidence there. The only problem is I hope to never use it on ISS, I’ve never had a fire. And so we had a look at that. The other thing we had to look at is on Shuttle and on ISS and actually on Apollo, if there was a fire, I put an oxygen mask on. I put an oxygen mask on my face, and remember I talked to you about, well I got to worry about oxygen percentage, right. My oxygen percentage gets too high, it’s going to be a problem. What was my oxygen percentage limit on Apollo? Well, it was 100 percent. So it doesn’t matter, you’re already there. You got other problems with 100 percent oxygen, but you’re already there and so you don’t have to worry about it.

Host: Yeah.

John Lewis: On Shuttle, and even moreover on Station, you have a very large cabin. And so the oxygen takes a long time to build up. I have a small cabin, so if I put on an oxygen mask, I would bust through my oxygen limits very quick. And so we looked at using cartridge-type masks that have scrubbing filters to pull out the carbon monoxides and the acid gases and all those things that are coming off this fire, and so what we’ve done is extensive testing because we’re kind of going outside of an ordinary experience base for us, and you’ve got to know what comes off of a laptop fire, because now I’m designing rocks to absorb it and keep it from the crew. And so we’ve got a whole team of folks that are setting laptops on fire and tablets on fire and extinguishing them and then learning what comes off of them and then making sure I can, make sure the crew breathes clean and that my cabin gets cleaned up by using that same kind of rock to clean it up.

And so it’s that, I’m torn between, you know, I have no quick trip home. I’ve got a really small volume, and I can’t use some of my classic devices. And then I’ve got some new things like laptop batteries, which make it more challenging.

Host: Yeah. One device that’s got to filter all of these different things, and is it part of that story that you were telling about, that one thing you had no idea that was like a part per billion, just testing for every–

John Lewis: Right.

Host: Yeah.

John Lewis: And that’s it. You find a lot of these, you know, it’s an alphabet soup of these crazy compounds that come off, and there are hazardous to crew at varied levels, and there’s even limited data on that. So the guys in space and life science have been doing a very thorough exhaustive search of, hey, you found this one crazy chemical Y. What is that? What does it do? What is the data we have on it? And what is the limit that we need to clean it down to. And we know from the fire test at White Sands how high it gets, and so we figured out how much scrubbing we have to do. And ultimately it all has to fit in the spacecraft. And we look at there’s two ways of doing it. I can either clean up the cabin good enough where I can take off my mask and get home for the rest of the mission, or if I can only clean it up good enough for the crew to be exposed to it for an hour, is I get in my suits, and I go ahead and de-press the cabin and then re-press the cabin back up again and get a fresh load of air in there to do that.

Host: Oh, okay.

John Lewis: And so, and so similar to shuttles used to purge–

Host: Purge.

John Lewis: Because shuttle had a lot of gas. They would just open up a vent and just purge it out.

Host: Yeah.

John Lewis: And shuttle also had 135 minutes to find a runway, and for us, we’ve got up to six days to get home. And so, again, I have to make sure that the crew, I can get them in a condition that they’ll be safe to get home.

Host: Yeah. Isn’t that like an engineer’s dream to be part of that team, that test, just like, all right, let’s just light stuff on fire and see what happens.

John Lewis: Yeah.

Host: Yeah.

John Lewis: Yeah, and it’s fun too because there’s a, you know, that’s the joy of working like this, is you get to get exposed to people that have an art and a craft to achieve that art, right.

Host: Yeah.

John Lewis: And whether it be lighting fires or figuring out how to make a chemical absorb something or figure out how to make a rocket engine work, and you get to see the passion and the thought that’s put into it, and they’re all really hard problems. It’s not, I would just add more of that, right. Just put another set of tires on the back of the truck. You’ll be able to carry more. It’s like, no, there’s only, I always say there’s only so much paint in a spacecraft, and you just got to move it around to cover it just right.

Host: Right.

John Lewis: And cover it just thin enough.

Host: Yeah. All right. So one thing that I wanted to end with, and we can go into a little bit more depth here, is the depressurization event, what would happen. Because you were mentioning several steps, you know. If there was a little depressurization, we can do this. But ultimately, worst case scenario, you depressurize and you have up to six days to figure out how to keep the crew alive and get home. So, how are those steps?

John Lewis: Yeah, that’s one of my biggest driving requirements is the–

Host: Really?

John Lewis: I get a hole in the cabin and you got to get the crew home.

Host: Yeah.

John Lewis: And so, the first thing you got to do is you got to go, hey, there’s a hole, tell the crew. And so we’ve got a smart sensor that goes, hey, that’s not normal. Pressure is going down faster than it should. Turn the horns on and wake everybody up, because you got limited time. Then the computer will look at it while the crew starts getting stuff together and goes, will tell them, hey, you’ve got 60 minutes or you’ve got four hours, right. And that’ll be able to tell them is this a fast leak or a slow leak or do I have time to go look for the leak, right. And so if it is a fast leak, the fastest leak we size for again is, it’s a quarter-inch hole, and I can allow the cabin to go down to the half atmosphere, and the crew will get their suits on, and everybody has to do a leak check. So what we’ll do is one guy will get his suit on. The other guys are still trying to get their suits on, and they’re configuring the spacecraft and doing a whole bunch of other stuff. And they’ll hop in, and they’ll do a leak check on their suit and make sure it’s good. Then they’ll plug in the next person, do a leak check on two, and then three, and then four, and then we also have enough time to say, well, when the last person finds a leak in their glove and they’ve got to depressurize and undo the glove or visor and cycle it and clear it out, we know we’ve got a good tight suit.

Because after that, the cabin goes to vacuum. We’ll hold the crew at 8 PSI in their suits, so they’ll all be Michelin men stuck in their suits.

Host: Yeah.

John Lewis: And we’ll let the cabin go down to vacuum. That is the challenge because just say to yourself, six days stuck in a suit, and you can imagine that it’s a challenge.

Host: Oh yeah.

John Lewis: And one of the things we ran into first was there’s the general ick factor, right. I’m in my restroom for that many days, and no matter what size diaper I wear, it’s going to not be able to do it, and the spacesuit guys are working on developing how do I manage that as best to keep the crew from getting any rashes or infections.

Host: Yeah.

John Lewis: But one of the things we found out early is when you urinate, you urinate a substance called urea, and what that urea does is when it gets around microbes and bugs, it turns into ammonia. That’s why if anybody has kids they know the smell of a baby diaper genie and it’s, you know, it’s ammonia right.

Host: Yeah.

John Lewis: And the ammonia gets up to a concentration where it would be fatal to the crew.

Host: Wow.

John Lewis: And so we have to make sure to get the urine out of the suit and vent it overboard. And it’s in a system similar to Apollo, a little more challenging with a mixed sex crew, but we’ve got to think about getting that urine out, because I cannot handle that. And so we keep the crew in suits for those six days. We think we have enough gas left over after I feed the leak that I can pressurize the cabin up to about a third of an atmosphere and get the crew mobility. Because they’re, remember when we talked about prebreathing at 8 PSI? It’s about 12 hours I’ve got to stay in that 9 PSI case, and then I will allow the cabin to go down, I mean the suits to go down to 4 to where there’s a little bit more mobility in the suits and they’re not this rigidized. Well then I can, right before we reenter, re-press the cabin to about the suit pressure to where there’s very little delta pressure across the suit, and so they get a lot more flexibility in the suit. And so then they can assemble the spacecraft for reentry, get the seats up, get in their seats, get strapped down. Then I’ll let the cabin go down again.

The next challenge is, is I come in through the atmosphere and I reenter. I’m going to be repressurizing the cabin from the outside because you’re dropping through the air so fast the pressure on the outside is building. And spacecraft are great at holding pressure in one direction, and that’s out. I can hold, you know, 14.7 normal atmosphere out. I probably can hold twice that, you know, from a design standpoint.

Host: Wow.

John Lewis: And so I’ve got structure holding it out. But holding it in, yeah, I can’t do anything holding it in. I can only hold about a PSI in. So one pound per square root inch higher on the outside. It’ll crush like a Coke can.

Host: Wow.

John Lewis: So we have valves that will open up and re-press from outside, so a big five-inch valve will start repressing air from the outside as soon as that pressure builds up. So as soon as I get within a half a PSI from outside to in, we’ll start repressing. So I’ve got two things I’ve got to do there. One, first off, I have the crew that is in their suits at about a third of an atmosphere, but the outside is repressurizing, and I’ve got to make sure to keep them above that or they’ll crush and go negative and get squeezed like a tube of toothpaste by the outside air pressure. So I’ve got to start feeding oxygen to repressurize the whole system to where when we land I’m always above that pressure. The other thing I’ve got to worry about is the outside of a spacecraft is a very stinky environment. I’ve got ammonia coming off of my cooling system. I’ve got ammonia coming off of my prop system. Because a byproduct of the propulsion system, the jets that keep the vehicle steered right going through the atmosphere is ammonia, the hydrazine fuels will break down into ammonias that come out.

And I don’t know if I’m ingesting those as I’m coming back down through the atmosphere, and so I’ve got to think about that and worry about that. And so on normal reentries, I’m going to put that air monitor that I pull out for fire, I’m going to hang it on the wall, and it’s going to tell me what the ammonia levels and the hydrazine levels even, even if I have a prop system that’s even letting pure hydrazine out. Because those are very toxic and very low levels, and so I’ve got to make sure the cabin is clean. Because the crew is going to look at that number and say, now we can clean that out. We’ll turn on the post-landing ventilation fan and scrub the cabin. Or guys, we’ve got ten minutes of oxygen in our suits, and let’s go grab the raft and let’s get away from the spacecraft because there’s too much of a hazardous environment. And so that whole scenario is if anything the one that makes all of us lose a little bit of sleep worrying about it and worrying the details, and that’s what drives the design of our suit systems, our cabin re-press systems and everything, is how to handle that possibility of a depressurized cabin return.

Host: Wow.

John Lewis: So–

Host: It’s pretty incredible all these different things that are trying to kill you during the whole space flight.

John Lewis: Yeah, yeah.

Host: But you can still design something where the crew is going to get in, and honestly, I think the crew is going to feel pretty comfortable based on what you’ve talked about with all the redundancies and everything. Looking forward to some of these first couple missions, EM-1, EM-2, actually testing. What are we looking for for the ECLSS side of the house? Where are we going to test some of this stuff?

John Lewis: So EM-1 is mostly active thermal–

Host: Okay.

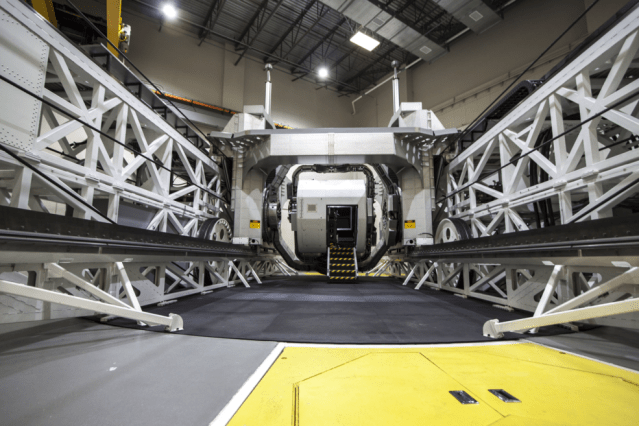

John Lewis: From the ECLSS active thermal, so it has all the cooling systems. For us, for ECLSS I has a nitrogen tank and a way to put that into the cabin because the cabin is going to be leaking, you know. It’s going to be up to, EM-1 can be up to 30 days, so it’s a longer duration than are even normal. And so, remember when I talked about how I don’t want to have less air on the inside of the cabin than outside, so I’ve got to be able to pressurize that. I also have my negative pressure relief valve. During that same time, we have test facilities down here where we’re going to be not only testing the components but integrating the suit loop and the pressure control systems and the chambers here in building seven. Actually the same chamber that we use to certify the lunar modules and all the EMUs, the spacesuits rather, we do spacewalks in.

Host: Yes.

John Lewis: And we’re going to convince ourself that I’ll run through the same scenarios that I would in the spacecraft, but I’ll do it in a manned or unmanned configuration where I can really push the system hard and know that I’m going to do that. So we’re, as a matter of fact, we’re getting ready to start another test to make sure that my oxygen system all the way from the European service module, going all the way into the Lockheed system, that all that system works together and is able to provide oxygen to crew and their suits and in the cabin, and so we’re getting ready to do testing late this year and early into next year to really run that out and run it to its extreme. And then we’re going to get a lot of the qualification hardware and integrate that into that same facility, and we will qualify the design that says, you got a hole in the cabin, get in your suit, make sure everything works, and I’ll convince that it works. My system, because I don’t have liquids separate from gases, like I did in an air conditioner condensing heat exchange on shuttle, I’m not as much driven by microgravity, and so I can test that a lot on my performance, but I am driven by pressure, so I need a vacuum chamber to vary my pressure around and make sure that works.

And so we’re doing a lot of testing on the ground, and in parallel, we’re right now doing preliminary and critical design review on a lot of the components for EM-1, and we’re going start, I’m sorry, for EM-2, for the manned mission, and we’re going to have those component being built this spring and being delivered early summer to the ONC building to start building up EM-2. And so we’re, we’re right in the tunnel and getting ready to go on that. So we’ll be, we’ll be sitting council on EM-1 and making sure everything is coming together on EM-2 and then worrying about all the tiny details of this didn’t work quite like I thought it did or this surprise came up and then working through that.

Host: Wow. All right. It’s going to ramp up isn’t it? This is an exciting time coming up.

John Lewis: Yeah, it is. Very exciting. Yeah.

Host: All right. Well, John, I think this was a fantastic overview of the ECLS systems. Everything from just how to make, you know, Orion support the humans to what happens in the worst case scenario, what are we going to do about it. So I appreciate you coming on. Thank you.

John Lewis: Yeah, no progress at all. Thanks a lot.

[ Music ]

Host: Hey, thanks for sticking around. So we talked with John Lewis today about Orion ECLS systems, environmental life control, going into everything about how the environment, the livable environment inside Orion is sustained to what happens in an emergency. You can check out one of our many episodes on Orion. We have a couple episodes scattered about in no particular order, but it’s just depending on whatever you wanted to listen to. We have a nice overview for Episode 17. We talk about how the crew is going to operate in missions up to 21 days, more like 16 days, on Episode 28. You can actually listen to the audio from inside one of the test missions for Orion for Episode 35. And if you go to NASA.gov/Orion, there’s an article called the Top Five Technologies Needed for a Spacecraft to Survive Deep Space. We’ve been going around and talking to all experts who have gone through these five technologies. They’re covered in Episode 67 with the heat shield. Episode 68 talks about navigation. Episode 75 more on radiation shielding, and this one on ECLS systems. We’ll get through all five eventually.

So on social media you can follow along with what’s going on with Orion on either the Orion accounts or the Johnson Space Center accounts of Facebook, Twitter, and Instagram. Use #askNASA on your favorite platform to submit ideas to the show. This episode was recorded on October 2, 2018. Thanks to Alex Perryman, Pat Ryan, Norah Moran, Laura Rashawn, Rachel Kraft, and Kylie Klem. Thanks again to Mr. John Lewis for coming on the show. We’ll be back next week.