Seconds matter in documenting flight tests of a new system intended to travel to space and back.

Just ask a group of pilots, photographers and videographers who have been documenting parachute tests in the Arizona desert aimed at ensuring the successful descent of the future Orion spacecraft as it comes back to Earth from deep space destinations.

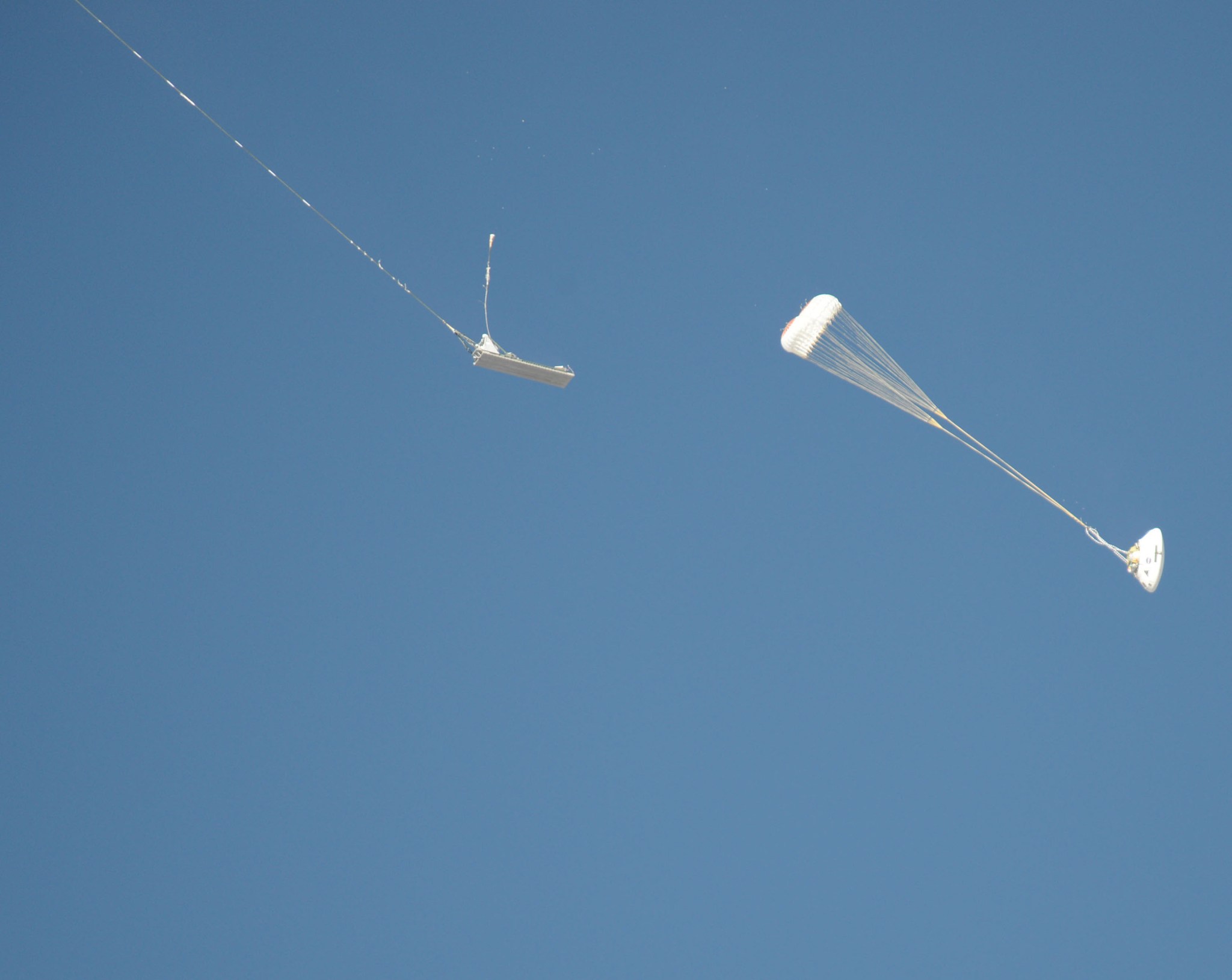

Photographers and videographers from NASA’s Armstrong Flight Research Center at Edwards, California, and the agency’s Johnson Space Center in Houston, only have moments to capture critical imagery engineers need to analyze the performance of the parachute system. It’s their job to document how the parachute system performs as a test version of Orion is extracted from a C-17 aircraft at about 25,000 feet altitude.

“The countdown is critical because I have 10 seconds to capture it, or I have nothing,” said Armstrong’s Carla Thomas of the key sequence she is responsible for documenting. She can shoot as many as 200 frames during the event.

Photographer James Blair of Johnson agreed time is short.

“It would be accurate to say fractions of a second count,” he said. “The various stages of chute deployment can be over in a blink of an eye.”

“There are no do overs and it’s all in the timing,” added Lori Losey, Armstrong’s NASA TV producer.

Thomas, Blair and Losey supported Orion parachute development tests at the U.S. Army Yuma Proving Ground near Yuma, Arizona, where NASA performs the tests, most recently on Aug. 26. One more in this development series is planned for November, leading to testing of the final design beginning in 2016.

Harold Robertson, deputy for test operations for the Capsule Parachute Assembly System project, explained the role of chase, photo and video support. Chase is a term used to describe an aircraft that accompanies the test aircraft to observe how events unfold.

“It’s extremely valuable. Parachutes are very difficult to instrument. A lot of the evaluation of the performance is watching how they fly,” Robertson said. “It’s really important for the engineers to be able to see the video and augment that with still photos for key events such as deployment and inflation.”

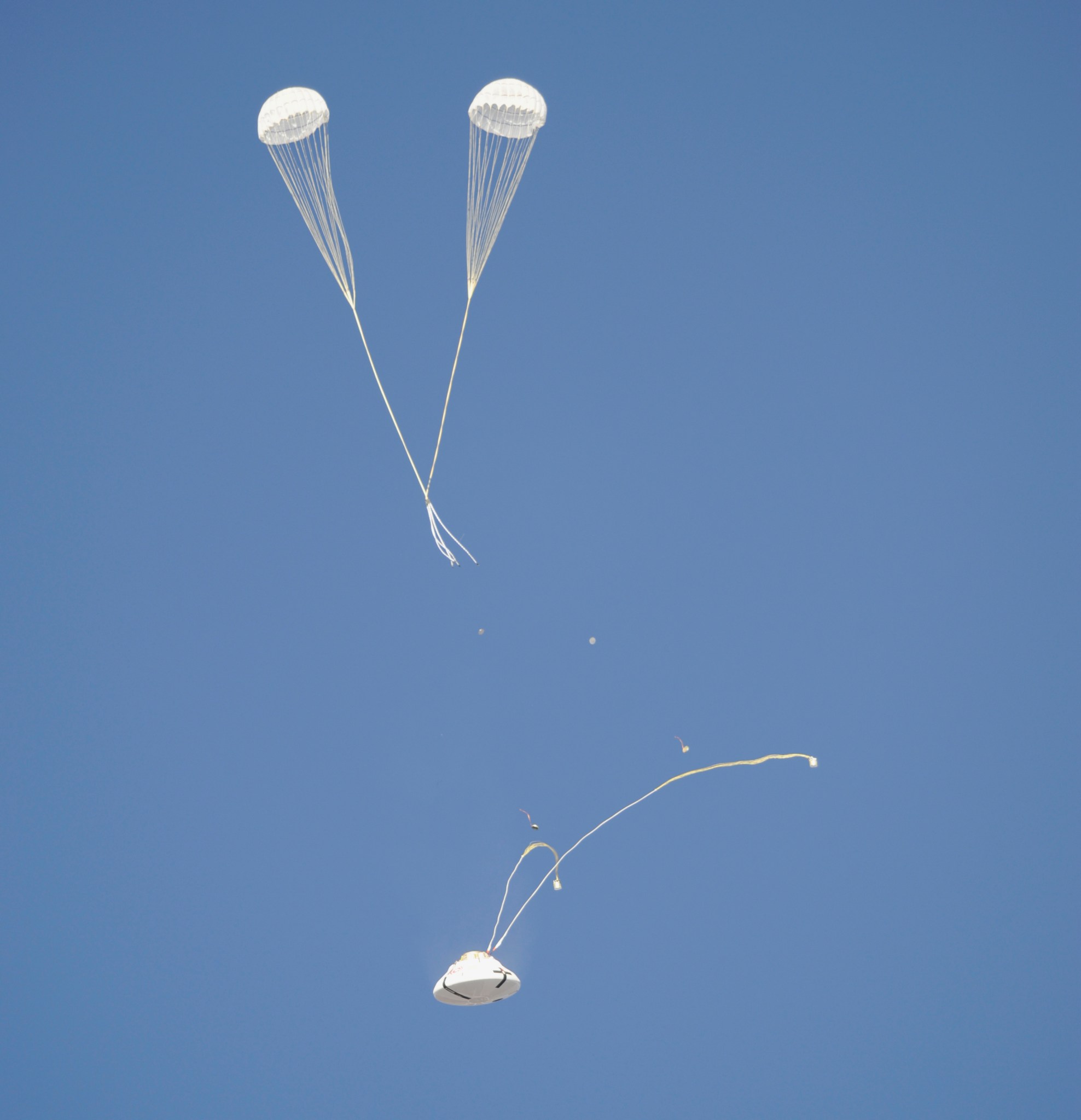

The engineering development tests have demonstrated the robust nature of the system by showing how it works in a number of deliberately arranged failures, such as when two parachutes were deliberately set to fail in the recent test. Each demonstration builds on and develops confidence in the overall system and answers questions that just can’t be modeled in the laboratory, Robertson said. The system has proven robust, but the documentation has been helpful for maturing several test techniques.

“We found two key issues from the video we collected from the chase aircraft, Robertson said, referring to challenges the team discovered years ago. “One is called extraction line whip. Essentially, when extraction parachutes used to pull the test article out of the airplane, it was like someone took a jump rope and whipped it all the way back to the system’s attach points causing some minor damage to the floor of the aircraft. Video taken from chase aircraft during the airdrop testing, and the tow tests we did in December 2013 at Edwards Air Force Base, helped resolve that issue.”

The second challenge involved higher loads on the reposition test equipment after the U.S. Air Force C-17 carried and dropped the mockup of Orion. The C-17 was based at the Air Force Test Center at Edwards Air Force Base, California.

“There is a single attachment point for the two extraction chutes and a deployment mechanism that changes the attachment from a single point to a dual point suspension,” Robertson explained. “That mechanism failed – it opened prematurely – even though it was a successful test. The platform parachutes deployed early and that was undesirable even though we were able to recover the platform successfully. The video we collected on that test was helpful in understanding what the problem was and working toward an engineering solution and to keep that from happening again.”

Extraction parachutes are parachutes used to pull the platform that the Orion mockup sits on in the aircraft away from it before the mockup is subsequently separated from the platform and the parachute system for the spacecraft begins deploying. The platform parachutes are then deployed later to slow it down and land the platform which allows for test equipment reuse.

Armstrong research pilot Denis Steele and associate director for Flight Operations Frank Batteas made a considerable contribution to obtaining documentation, Robertson said. Steele and Batteas determined a flying pattern and altitudes for as many as five aircraft involved in each test that would allow photographers and videographers to keep the test article in view longer to gather the most documentation.

“Within 10-15 seconds after the test article comes off the platform, the next five seconds are critical,” said Jim Ross, Armstrong photo chief. “It is easier to take images because the aircraft is at the same altitude as the C-17. I shoot until I can’t see the parachute system.”

Batteas explained development of a detailed timeline of key events from the point the platform is dropped from the C-17 was an important job for the team.

“We try to capture all of that in the first 18 seconds with high speed video by turning our aircraft so the parachute system is in sight as it exits the airplane,” Batteas said. “We capture the very first part that they are looking for which is the exit of the platform and test article from the C-17. After that, anything we can get is good for them because there are a lot of dynamics that happens as the platform separates from the test article.”

Blair has supported the Orion parachute tests since 2008 and described his first time as a photographer in the UH-1 chase helicopter.

“I was placed in the back seat known as the ‘hell hole’ because of the extreme wind and vibration that position experiences,” he recalled. “It lived up to its reputation with my hands going numb from cold. Looking through the camera’s viewfinder and spotting the test article was also a challenge due to the camera movement.”

His experience in Yuma paid off during the Orion flight test last December, as he documented Orion’s reentry from space from a U.S. Navy SH-60S Seahawk during the recovery efforts. “It was an experience of a lifetime,” he said.

Flight testing of the parachute system began in 2007. The final round of Orion qualification parachute tests are scheduled to be complete in 2019, when the system will be ready to provide the Orion spacecraft and its crew a safe return from space.

Johnson’s Engineering Directorate manages the Capsule Parachute Assembly System project for Orion. Team members include NASA, Jacobs Engineering, Lockheed Martin, Fox Parachute Services and Airborne Systems of Santa Ana, California, where the parachutes are manufactured and packed.

View some of the parachute tests here: https://www.youtube.com/user/NASACPAS