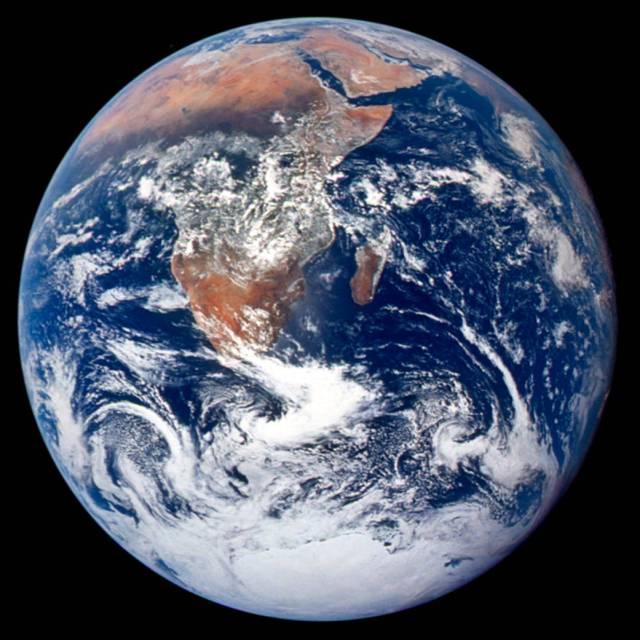

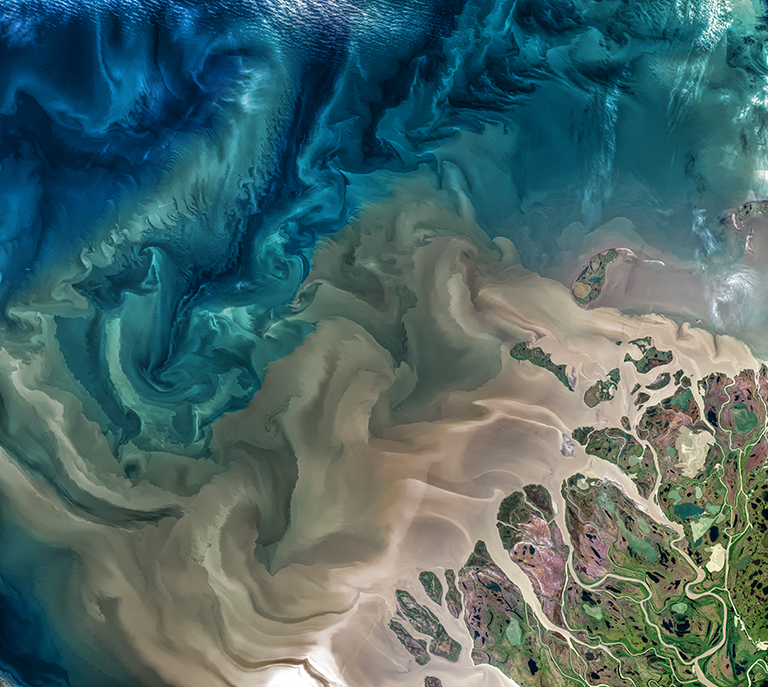

It’s rocky. It’s sandy. It’s flat. It’s cratered. It’s cold. The surface of Mars is a challenging and inhospitable place, especially for rovers. As future missions to Mars become more complex, NASA’s robotic wanderers will need new technologies to look deeper into the history of the Red Planet.

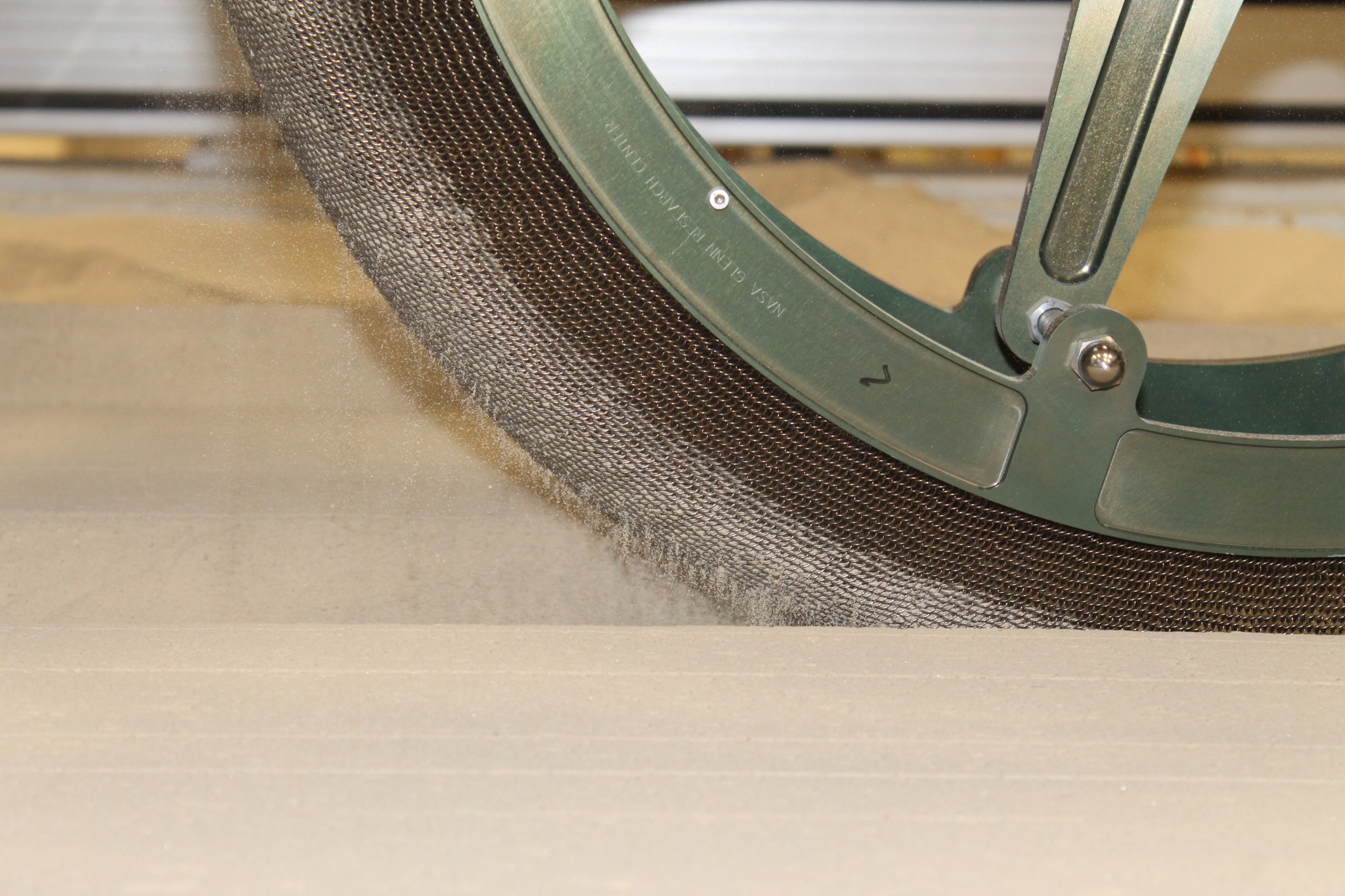

One of those technologies is an innovative new tire in development at NASA’s Glenn Research Center using innovative shape memory alloys (SMA).

Tires made from these shape-shifting materials offer unmatched durability because they flex with the terrain unlike current rigid wheels. They can actually envelop rocks without the risk of puncture. And they can be designed to provide a smoother ride – almost like adding shock absorbers – to minimize potential damage to systems on the rover.

“Glenn began working with the U.S. tire industry years ago to develop a better non-pneumatic, or airless, tire for the Moon,” said Vivake Asnani, lead tire engineer at Glenn. “This led to an advanced tire known as the Spring Tire, constructed using a network of steel springs, that adapted and contoured to terrain like a traditional rubber tire.”

Glenn engineers have since replaced the conventional steel with springs made of SMA to improve a rover’s ability to operate in extremely rocky terrain and at the cold temperatures of Mars. This is appealing to mission planners for future use on Mars because of its lighter weight, traction performance and durability.

Engineers are now refining SMA materials processing, working designs and completing environmental testing on a new Mars tire at Glenn’s Simulated Lunar Operations Lab.

“We’re developing a Mars-grade material that greatly improves SMA capability and makes reversible material deformations possible in the harsh Martian environment without sacrificing performance,” said Dr. Santo Padula, lead SMA materials and design engineer at Glenn.

Testing has proven the tire’s superior grip meets or exceeds all traction performance demands and will give rover drivers the ability to cross varying terrains. The more capable tires also allow for a rover design using four tires as opposed to the past six-tire configurations. So, in the case of future human exploration or robotic missions, these tires can provide valuable flexibility in the vehicle and spacecraft design.

The next of NASA’s Mars exploration missions, Mars 2020 and its Perseverance rover, is scheduled to launch in July.

Meanwhile, engineers at Glenn will continue to mature SMA technologies for applications on Mars and here on Earth, including passenger vehicle, military and aircraft tires. A concept SMA passenger tire has been tested, and could eventually replace conventional air-filled tires, eliminating the risk of punctures and driving under-inflated, while improving fuel efficiency and safety.

Jimi Russell

NASA’s Glenn Research Center