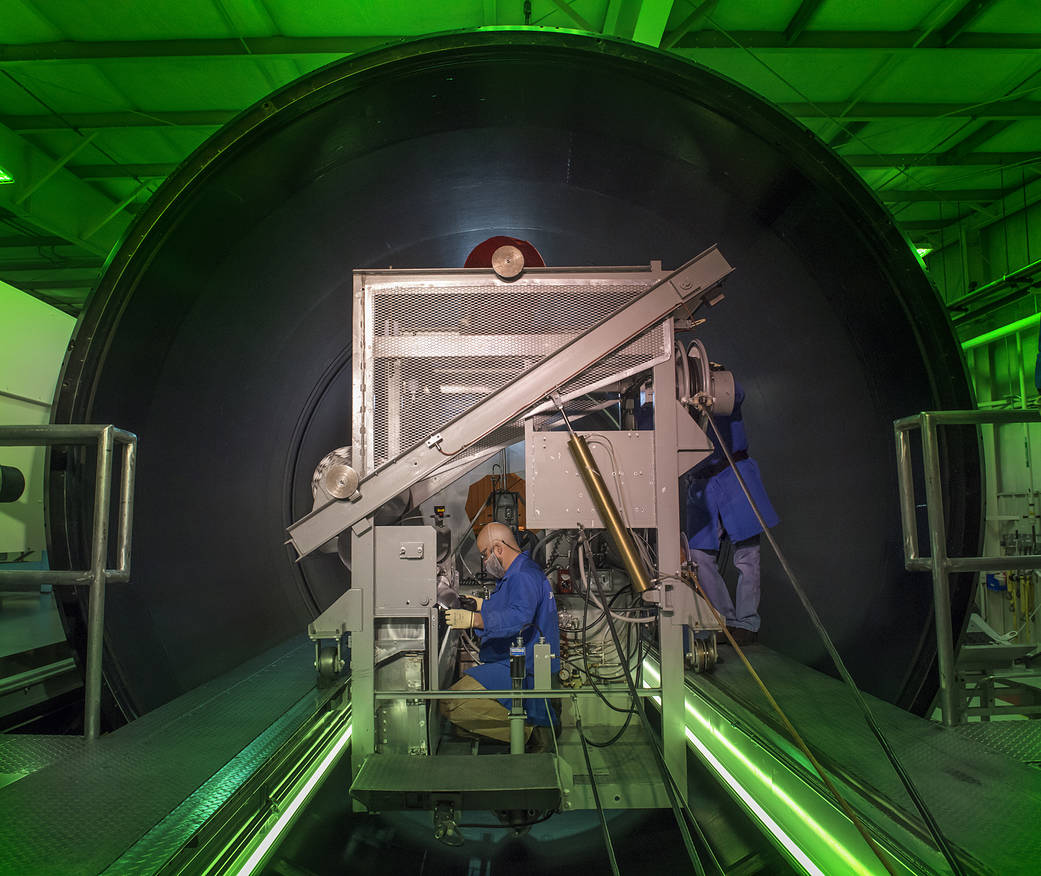

NASA and Northrop Grumman technicians in Promontory, Utah, have applied insulation to the final booster motor segment for the second flight of NASA’s deep space rocket, the Space Launch System, and NASA’s Orion spacecraft. The insulation, applied to the interior of each steel motor segment, protects the casing from the heat generated by the propellant during launch and flight. The twin, five-segment solid rocket motor boosters for SLS are the largest, most powerful solid propellant boosters ever built. SLS uses both liquid and solid propellant to provide the thrust needed to launch the vehicle and send it to space. The boosters provide more than 75% of the total thrust at launch and into the first two minutes of flight. Five motor segments are stacked together to create a single, very large motor for each booster. The manufacture and checkout of all 10 motor segments for the first test flight of SLS and Orion were completed earlier this year.

NASA is charged to get American astronauts to the surface of the Moon by 2024. SLS and the Orion are our backbone for deep space exploration. SLS and Orion will launch from NASA’s Kennedy Space Center in Florida on missions to the Gateway in lunar orbit. NASA is targeting 2022 to test SLS with astronauts aboard the Orion spacecraft.

Image Credit: Northrop Grumman Photo