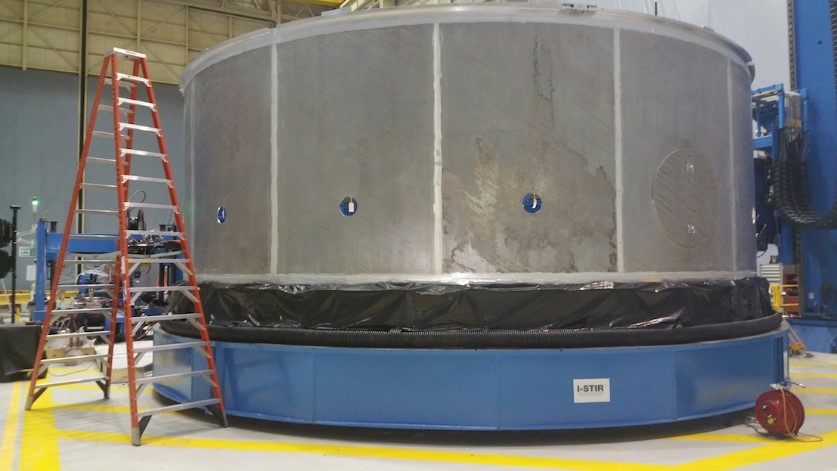

Engineers recently completed fabrication of the core stage simulator structural test article for NASA’s new rocket, the Space Launch System (SLS). The SLS will be the most powerful rocket ever built for deep space missions, including to an asteroid and ultimately to Mars.

The structural test article is a replica of the top of the core stage and is approximately 10 feet tall and 27 feet in diameter. The rocket’s core stage, towering more than 200 feet tall, will house the vehicle’s avionics and flight computer. It also will store cryogenic liquid hydrogen and liquid oxygen that will feed the vehicle’s RS-25 engines. When combined with two five-segment solid rocket boosters, the rocket will produce 8.4 million pounds of thrust at liftoff to carry 154,000 pounds.

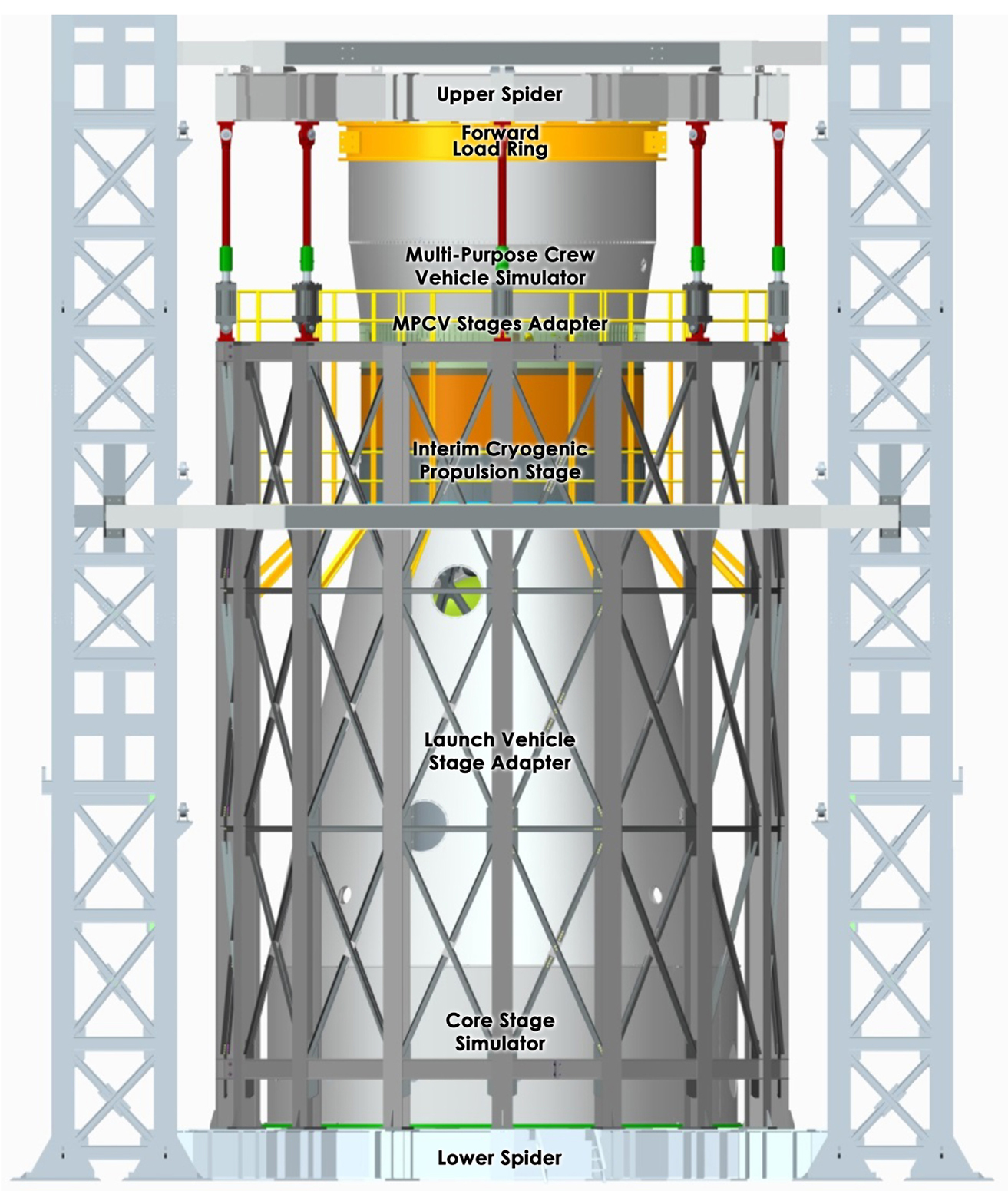

The full configuration at launch includes several parts that are stacked on top of the core stage to reach a total height of 322 feet. When the test versions of all the parts are completed, engineers will stack the 56-foot tall structure at a Marshall test stand for testing to verify the integrity of the hardware and ensure it can withstand the loads it may experience during flight. They include:

- Orion spacecraft – designed to carry the crew to distant planetary bodies; provide emergency abort capability; sustain the crew during space travel; and provide safe re-entry from deep space

- Multi-purpose crew vehicle stage adapter – connects the Orion spacecraft to the SLS

- Interim cryogenic propulsion stage — gives the Orion spacecraft the big push needed to fly beyond the moon before the spacecraft returns to Earth for the first flight test of SLS

- Launch vehicle stage adapter — used to connect the core stage and interim cryogenic propulsion stages

“Our engineering workforce has the expertise to produce large test articles, such as the core stage simulator,” said Keith Higginbotham, integrated structural test lead in the Spacecraft/Payload Integration & Evolution (SPIE) Office at NASA’s Marshall Space Flight Center in Huntsville, Alabama, where the work is being conducted, and the SLS Program is managed for the agency. “We’ve made a tremendous amount of progress and look forward to testing.”

After inspections and final machining, the core stage simulator test article is scheduled to be completed by mid-April. Engineers have already completed structural test articles of the multi-purpose crew vehicle stage adapter and Orion spacecraft simulator, and test articles for the interim cryogenic propulsion stage and launch vehicle stage adapter are currently in production.

“Our skilled, talented engineering and technician team members, manufacturing capabilities and robotic welding facilities allow us to build these critical large space structures for Space Launch System testing at the Marshall Center,” said Tim Vaughn, chief of the Metals Engineering Division in Marshall’s Materials and Processes Laboratory. “The lessons we learned building the core stage simulator has helped us hone processes that we will use to produce other SLS test hardware.”

At the same time, the SPIE Office kicked off its critical design review March 19, which is a major milestone for the program and proves the hardware is mature enough for production. This is the last rocket element to undergo a critical design review before the SLS Program begins its integrated critical design review this summer.

The first flight test of the SLS will feature a configuration for a 70-metric-ton (77-ton) lift capacity and carry an uncrewed Orion spacecraft beyond low-Earth orbit to test the performance of the integrated system. As the SLS evolves, it will provide an unprecedented lift capability of 130 metric tons (143 tons) to enable missions even farther into our solar system.

For more information about SLS, visit: