Credits: STScI

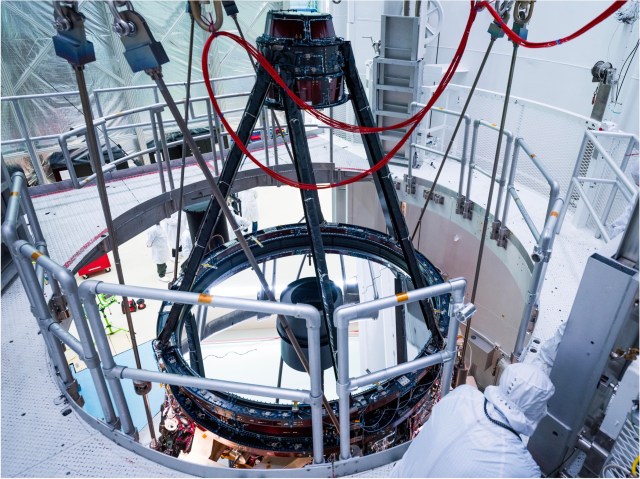

The newest video in the “Behind the Webb” series takes viewers behind the scenes to reveal how the pieces that make up each layer of the James Webb Space Telescope’s thin sunshield are bonded together.

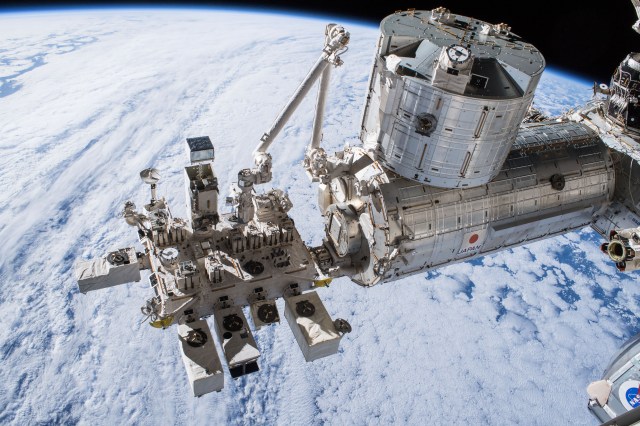

NASA’s Webb telescope has a five-layer sunshield that is as large as a tennis court. The sunshield will help keep the infrared instruments aboard as cold as possible by blocking out heat and light.

The video called “Webb’s All Sewn Up” was produced at the Space Telescope Science Institute or STScI in Baltimore, Md. and takes viewers behind the scenes with engineers who are testing or creating the Webb telescope’s components.

In the 4 minute and 9 second video, STScI host Mary Estacion takes the viewer to the Mantech facility in Huntsville, Alabama, to find out just how engineers on the ground are working with the sunshield layers and binding them together.

Mary interviewed John Cranston, the sunshield process engineer at Mantech’s NeXolve Corporation who described Kapton, the raw material that creates the sunshield. NeXolve is a subsidiary of ManTech International Corporation and completed the manufacturing of all template layers for the Webb Telescope sunshield.

Cranston showed viewers Kapton and explained how the aluminum and silicon coatings that are applied to some sunshield layers work.

Each of the five layers consists of at least 55 individual pieces or “gores” of Kapton bonded together, and each layer is shaped slightly differently. The first layer faces the sun and will be the hottest, while the fifth layer faces the telescope and instruments and will be the coolest.

Bonding the extremely thin gores of the sunshield together to achieve precise shapes is vital to the sunshield’s performance and was a significant engineering challenge. Engineers couldn’t use glue because it would add too much mass.

In the video, Mary takes viewers to see where the individual pieces will be seamed together by a thermal welding technique on what is called the “spot bonding machine.” The machine applies just the right amount of heat to the material in small spots to fuse it together but not so much that it burns through.

The “Behind the Webb” video series is available in HQ, large and small Quicktime formats, HD, Large and Small WMV formats, and HD, Large and Small Xvid formats.

To see the Behind the Webb’s “Webb Sunshield All Sewn Up” video, visit: http://webbtelescope.org/webb_telescope/behind_the_webb/21

Rob Gutro

NASA’s Goddard Space Flight Center