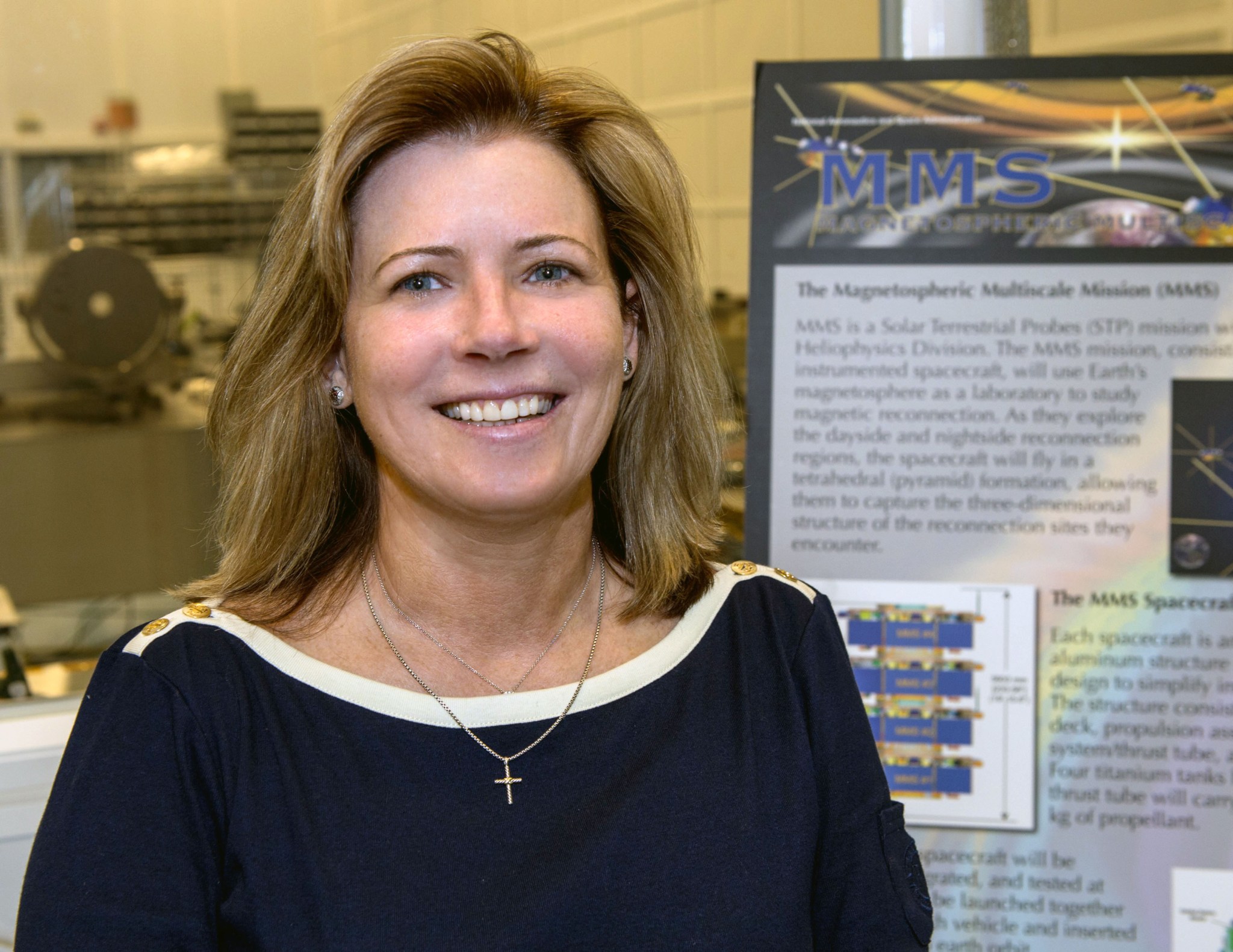

Name: Lori L. Mooney

Title: Contamination control technician

Organization: Code 540.5, Contamination Control

NASA Goddard’s Martha Stewart, contamination control technician Lori L. Mooney ensures that cleanliness makes for successful launches.

What do you do and what is most interesting about your role here at Goddard? How do you help support Goddard’s mission?

My job is to minimize contaminates, such as particles, and molecular (i.e. oils, silicones) that can contaminate the spacecraft, instruments, or even the clean room where spacecraft and instruments are built. All projects require a certain threshold of cleanliness which depends on the goal of the project and the sensitivity of the hardware.

The smallest particles of contamination can cause total failure of the hardware and ultimately the project. One single speck of dust in the wrong place could cause an instrument to fail. Many of our instruments and spacecraft built here at Goddard are extremely complex and very sensitive.

Cleanliness and contamination control is all about preventing failure; we don’t want any failures!

What do you do to keep everything as clean as required?

We start before the project even enters the clean room where we build the spacecraft and instruments. Everything comes through our pre-clean area before entering the clean room.

First, our contamination control team cleans everything in the empty clean room to bring it into certification compliance and is required by the projects. We mop the floors and we wipe down all horizontal and vertical surfaces in an effort to meet the project’s particulate threshold.

Once we get the empty clean room to the required cleanliness level, we then begin processing the hardware. We clean every single piece of hardware or item before it is placed into the clean room. Whether the item is a screwdriver or a solar array, the standard of cleanliness is the same. Our standard of cleanliness is always very high, as it meets or exceeds both project and procedural requirements!

Our cleaning protocols depend on the project’s wishes. We use various solvents such as isopropyl alcohol, acetone and hexane. We also use special wipes, nitrile gloves and latex gloves when handling all hardware. The cleaning solvents, wipes and gloves are individually tested and certified for cleanliness prior to use.

How do you make sure that people entering the clean room are free of particulates?

We have certain rules – no jewelry, no perfume and no makeup. We wear facemasks in case we sneeze or cough, which produces particles. We also try to minimize movement within the room which can contribute to increased particle counts.

We are not allowed to bring in cell phones. We have tiny lockers right outside of the clean room just big enough to fit a cell phone.

Before entering the clean room everyone signs in a logbook for control purposes. Everybody then puts their regular street shoes on a mechanized cleaning brush to remove outside particles from their street shoes.

We next walk through an air shower in which very strong air jets blow the particles off regular garments and skin.

Then comes the gowning area. We wear “white bunny suits,” which are special clean room garments that are individually tested and certified for cleanliness. Staff at the laundering company that processes our clean room garments actually wear bunny suits while performing the laundering process. The bunny suits consist of a one-piece jumper with a separate hood. We also wear special blue gloves, boots and a white face mask. The material is designed to minimize electrical static discharge which could severely harm any of our very sensitive electrical instruments.

The entire gowning process takes about half an hour. Although the bunny suits can get hot and feel uncomfortable, they are critical to maintaining cleanliness.

Can you please describe the clean rooms?

Goddard is home to one of the world’s largest clean rooms, the Space Systems Development and Integration Facility, or SSDIF, which is an 86,000-square-foot clean room. There are different levels of cleanliness authorized for clean rooms. The SSDIF is certified to the International Standards Organization, or ISO, as a Class 7 clean room and operates at a much cleaner level as you approach the large filter wall. We have several clean rooms across the center, and each has unique requirements. Many are designated by names, such as the Spacecraft Checkout Area. Additionally, the Hubble Space Telescope was assembled in the SSDIF and now the James Webb Space Telescope is being assembled in the SSDIF.

The SSDIF and other clean rooms have their own separate HVAC systems with HEPA filtration that can be controlled to re-circulate the air or add in made-up air from the outside.

Read Part Two of Lori Mooney’s interview

Read more Conversations With Goddard

Also read about what our people do Outside Goddard