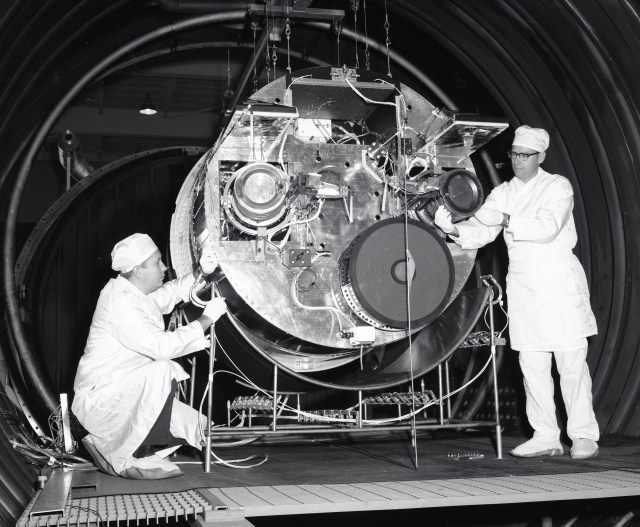

When Tony Mendez looks at a Space Shuttle Main Engine (SSME), he sees a highly durable, specialized, complex machine that’s done for more than 20 years exactly what it was designed to do: propel the world’s only reusable winged spaceships.

Mendez, an SSME technical associate with Boeing Rocketdyne at NASA Stennis Space Center (SSC), is one of about 130 engineers and technicians who work with SSMEs on a daily basis. Their work is helping NASA carry out its plan to return the Space Shuttle to flight following the loss of Space Shuttle Columbia in February 2003. That plan plays a key role in NASA’s Vision for Space Exploration, which includes completing work on the International Space Station by 2010.

Mendez works on SSC’s A-2 Test Stand, where his job on a recent afternoon included reading a mass spectrometer to ensure against leaks in the SSME heat exchanger.

“I look at this engine a lot differently now than I did the first time I saw it 20 years ago,” Mendez said. “Everything has its place. I can tell right away if something’s not right.”

Mendez, who lives in Picayune, is not alone in his knowledge of the SSME, his longevity on the job or his dedication to it.

“I make sure every time I do something, I do it 100 percent right,” he said. “Every person working here feels the same way.”

“The Columbia accident really put us under a microscope,” said Rene LeFrere of Slidell, La., an aerospace product technician with Boeing. “Of course, the accident had nothing to do with the engine, but it still makes us ask ourselves every day: ‘Are we conducting the processes correctly? Are we paying attention to detail?’ We don’t take anything for granted.”

LeFrere works with Danny Wheat of Picayune, also an aerospace product technician, in Boeing’s SSME warehouse and engine assembly facility, across the SSC campus from the A-2 Test Stand. Wheat has worked on SSMEs for 26 years.

He compared the current Return to Flight initiative with that following the Challenger mishap in 1986.

“These tragedies make you feel so helpless,” Wheat said. “We’re always careful, but after Columbia – and after Challenger – we became even more so. The astronauts go through so much to get up into space for themselves and for their country. You don’t want to see anything get in the way of that.”

Because the lives of Space Shuttle astronauts depend on their vessels, Technician Don Albritton of Picayune sees it as his personal mission to make sure nothing erodes the astronauts’ confidence in “his” engines.

“Their lives are on the line,” said the 11-year Boeing veteran. “What we do determines if their mission succeeds. It all boils down to assuring their safety. It makes me proud to be part of the team that accomplishes that goal.”

Terri Bennett, also of Picayune, echoed Albritton’s sentiments. “We are a confident group. We all take pride in what we do.”

One of the first women to work in SSC’s engine test complex, Bennett started nearly 20 years ago as a mechanic. She is now a Boeing lead quality inspector on the A-1 Test Stand. Dedication to the space program is a family tradition. Her father, James Bennett, started work at SSC (then called the Mississippi Test Facility) during the 1960s, when NASA was testing the Saturn engines that carried humans to the Moon. He retired from SSC in 1992.

“The first time I saw a Space Shuttle launch, I was overcome with emotion,” she said. “Especially right before the engines shut down, because up until that moment, it was MY engine. There is nothing like knowing you can take that thing apart and put it back together.”

Space Shuttle Discovery, NASA’s Return to Flight mission STS-114, is scheduled to launch this year. While the orbiter Discovery undergoes extensive modification and maintenance at Kennedy Space Center in preparation for its return to flight, SSC engineers, mechanics and technicians will go quietly about their work, making sure “their” Space Shuttle Main Engines continue to operate safely and perform well.

“This machine is so complex, but it works so flawlessly,” Wheat said. “Our job is to make sure we work out any possible problem here – in processing or on the test stand – long before it gets to the launch pad or up into orbit.”

Related Multimedia:

+ https://www.nasa.gov/centers/stennis/news/newsreleases/2004/STS-05-020-cptn1.html

– end –

text-only version of this release

John C. Stennis Space Center

Stennis Space Center, MS 39529-6000

(228) 688-3341