Marshall Space Flight Center

Capabilities

Pictured at sunset is Marshall Space Flight Center’s Propulsion R&D Lab, Building 4205.

NASA/Charles Beason

Propulsion

- Propulsion Systems Design

- Propulsion Systems Design and Integration

- Component Design and Development

- Propulsion Structural, Thermal & Fluid Analysis

- Solid Propulsion Systems

- Propulsion Systems Research and Development Labs

A laser powder directed energy deposition nozzle head building layers of JBK-75 alloy. Engineers and technologists at Marshall lead metal additive manufacturing, or 3D printing, developments for propulsion applications to mature processes.

NASA

Materials and Processes

- Materials and Processes Laboratory

- Advanced Manufacturing

- Mechanical Testing

- Damage Tolerance

- Material Diagnostics, Metallurgy, and Failure Analysis

- Advanced Metal Joining Facility

- Nonmetallic Materials

- Digital Manufacturing

- Additive Manufacturing

- Composites Manufacturing

- Electrostatic Levitation Laboratory

- Space Environmental Effects

- High Intensity Solar Environment Testing

- Tribology and Metrology

- Solar and Ultraviolet Radiation Testing

- Impact Testing Facility

Advanced Concepts

The Advanced Concepts Office (ACO) performs early-phase analyses and feasibility evaluations of space systems for planning purposes.

View the PDF about Advanced Concepts

Space Transportation Systems

- Spacecraft & Vehicle Systems

- Structural Design and Analysis

- Flight Mechanics and Analysis

- Systems Engineering and Integration

Space Systems

- Space Systems

- Systems Engineering and Integration

- Mechanical & Optical Design, Analysis & Fabrication

- Avionics Design

- Systems Development, Integration & Test

Westward-facing view of Buildings 4221 (left) and 4203 on Marshall Space Flight Center campus

NASA/Emmett Given

Specialized Test Capabilities

- Test Laboratory

- Propulsion Test Laboratory

- Aerodynamic Research Facility

- Environmental Test Facility

- Fluid Dynamics

- Structural Strength Test Lab

- Structural Dynamics Testing

- Special Test Equipment Design

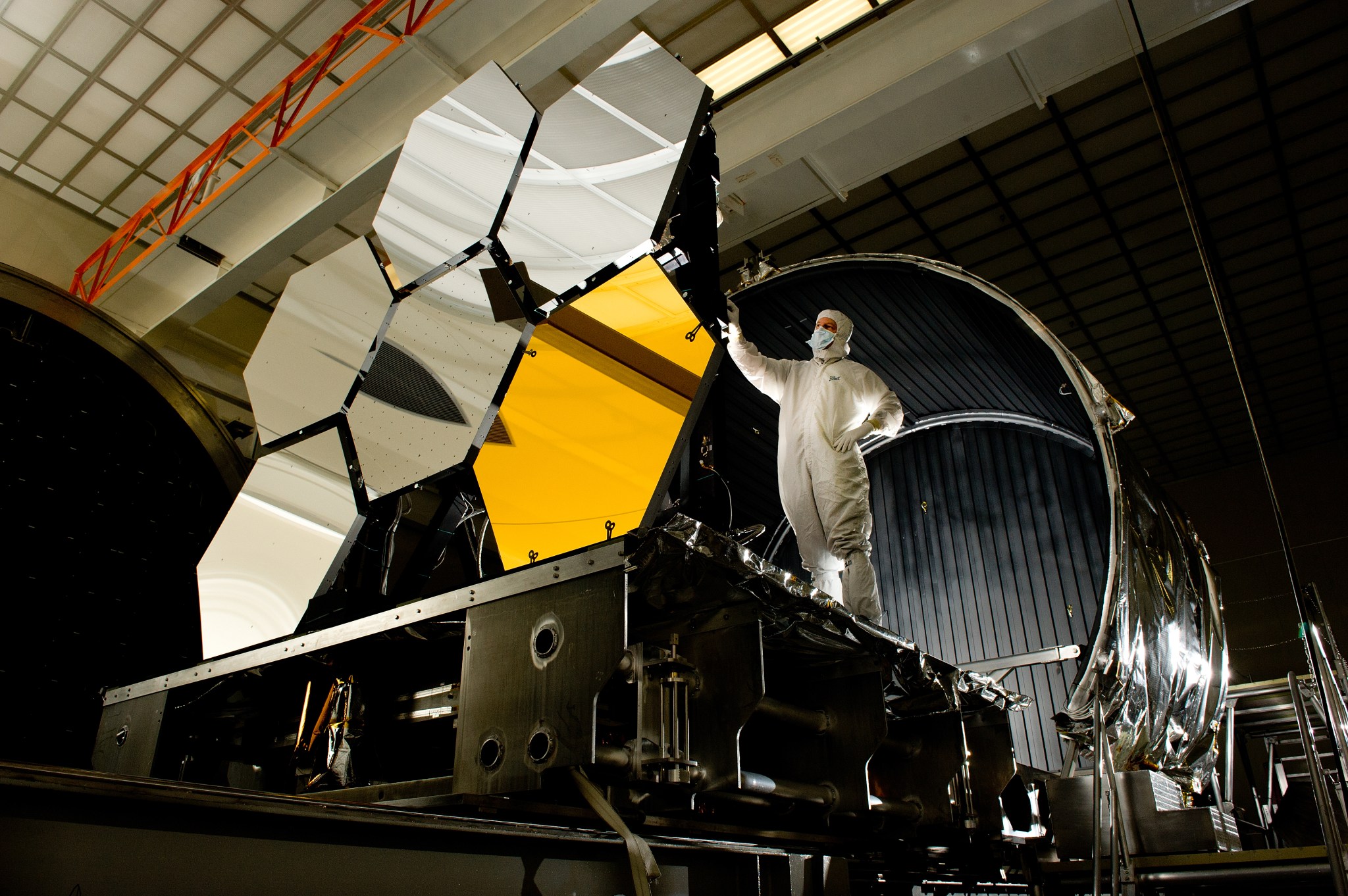

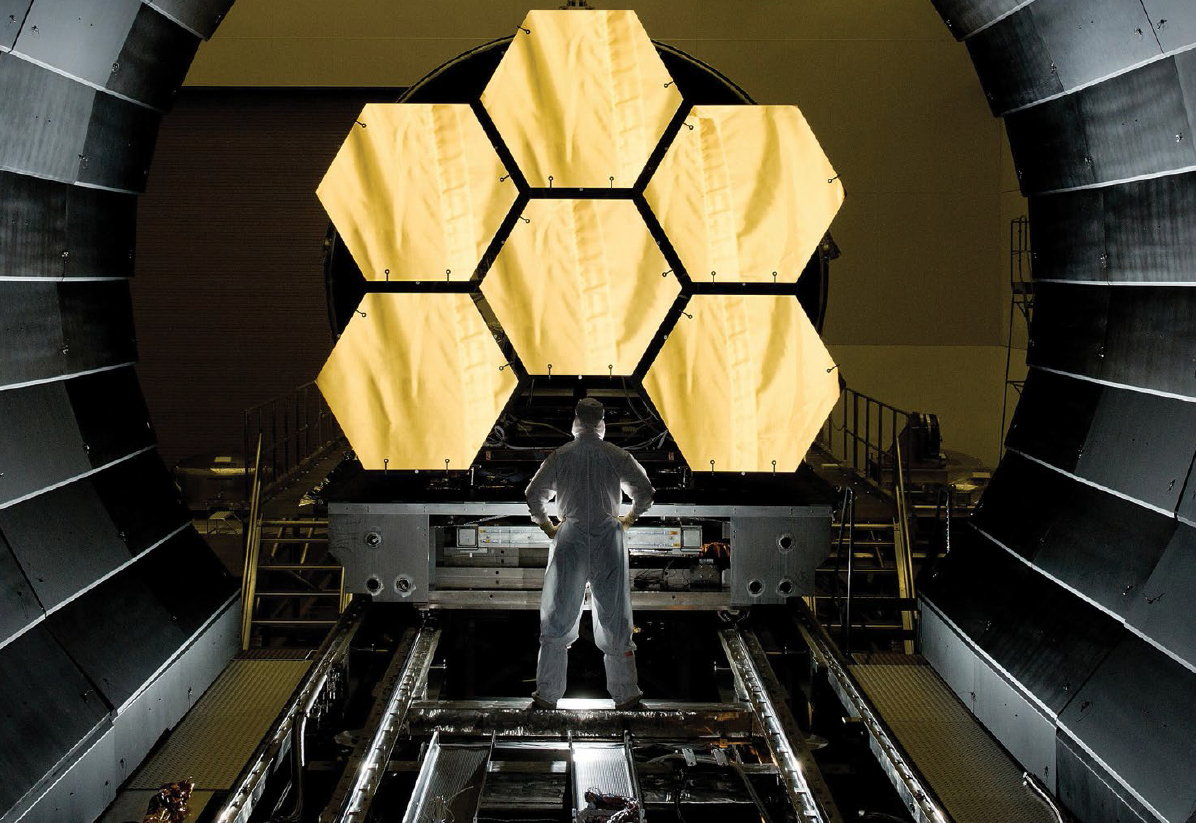

Six of the 18 segments that form NASA’s James Webb Space Telescope’s primary mirror are pictured before undergoing cryogenic testing in 2011 at Marshall Space Flight Center in Huntsville, Alabama.

Payload & Mission Operations

- Payload & Mission Operations

- Science Mission Operations

- Science Mission Operations Training

- Mission Training Complex

The Payload Operations Integration Center (POIC) after installation of new wall monitors.

Do Business with Marshall

Learn how you can work with NASA's Marshall Space Flight Center. Companies, academic institutions, state and other federal agencies can use NASA resources to support their needs and initiatives that align with NASA’s mission.

Learn More about Do Business with Marshall