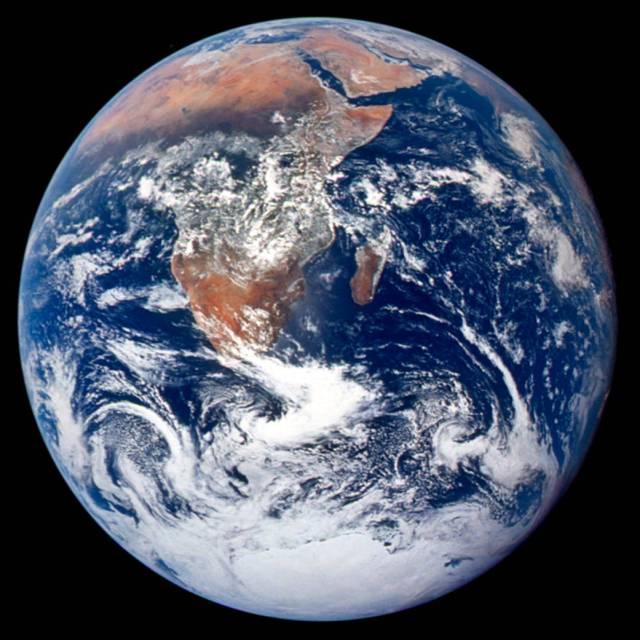

NASA’s commercial space partners continue to meet milestones under agreements with the agency’s Commercial Crew Program (CCP), as they move forward in their development of spacecraft and rockets that will transport humans to destinations in low-Earth orbit.

The achievements in February are the latest development in a cycle that is seeing all four industry partners meet their milestones in their Commercial Crew Integrated Capability and Commercial Crew Development Round 2 agreements with the agency.

Blue Origin, The Boeing Company, Sierra Nevada Corporation (SNC) and Space Exploration Technology (SpaceX) are developing unique transportation systems and face challenging evaluations and tests in 2014. CCP’s engineering team is working closely with its partners as they develop the next generation of crewed spacecraft. Ultimately, NASA intends to certify and use commercial systems to fly astronauts from the United States to the International Space Station, and back.

“We have been very pleased to see all the companies in this extraordinary partnership continue to hold to schedules of development that keep us on a path to resume flights into space for astronauts on American-made spacecraft lifting off from U.S. soil,” said Kathy Lueders, acting CCP program manager.

Blue Origin completed a review of the design, manufacture and assembly of its sub-scale propulsion tank, a smaller version of the tank that will boost the company’s Space Vehicle into low-Earth orbit. Engineers will use the results to evaluate design features and manufacturing processes for orbital operations.

Boeing wrapped up a critical design review of the primary structures for its CST-100 spacecraft in late February that advances the design of many of the spacecraft structures to a point at which fabrication can begin. The primary structures are comprised of two major components — the crew module and the service module. The crew module is the pressurized shell where the crew sits during a mission. The shell also contains the computers, cooling systems and other critical components to keep the flight crew and their cargo safe during flight. The service module houses propulsion and abort systems, used to maneuver the spacecraft during flight.

The critical design review was backed up by significant materials testing to verify the materials would hold up to the strenuous demands of spaceflight. One of the challenges in developing a primary structure for spacecraft is to make it light, but still have the strength to tolerate the rigors of spaceflight, and to safely house the vehicle’s critical components.

Also in February, SpaceX completed an early design review for the ground systems it anticipates using at NASA’s Kennedy Space Center in Florida to launch the company’s crewed Dragon spacecraft on the company’s Falcon 9 rocket. NASA engineers reviewed plans to adapt existing structures at Kennedy to accommodate the rocket. Because the Dragon spacecraft will be flying people, the ground system designs have to include ways for the crew to safely enter the spacecraft at the top of the rocket, plus a means for them to evacuate the pad quickly in the unlikely event of an emergency.

All four of NASA’s industry partners continue to meet their established milestones in developing crew transportation systems and are preparing for several more. Blue Origin is working toward the interim design review of its space vehicle subsystems. Boeing’s next milestone comes in April when the software for the CST-100 goes through a critical design review.

As with hardware elements of the spacecraft, the software has undergone numerous tests and simulations to confirm it will hold up to the demanding realm of spaceflight. SNC is preparing to evaluate the data from numerous wind tunnel tests of its Dream Chaser spacecraft and United Launch Alliance Atlas V rocket integrated stack configurations at NASA’s Langley and Ames Research Centers. SNC also is actively conducting several reaction control systems and main engine motor tests at their Poway, Calif., facility. These evaluations and tests are crucial tools for advancing SNC’s spacecraft. Also in April, SpaceX will complete an integrated critical design review that will cover all elements of the crewed Dragon spacecraft and Falcon 9 rocket. This precedes a busy summer for the company as preparation continues on two launch abort system test flights later this year.

Milestones achieved by CCP’s partners continue to advance commercial spacecraft and transportation systems from design to reality. The successes of NASA and American aerospace companies are ushering in a new generation of space transportation capabilities, which will enable new opportunities for humans to live and work in space.

For more information about CCP and its aerospace industry partners, visit:

https://www.nasa.gov/commercialcrew

-end-

Stephanie Martin

Kennedy Space Center, Fla.

321-867-2468

stephanie.a.martin@nasa.gov

Trent J. Perrotto

Headquarters, Washington

202-358-1100

trent.j.perrotto@nasa.gov